In essence, vacuum deposition is a family of processes used to apply an exceptionally thin, uniform layer of material onto a surface inside a low-pressure vacuum chamber. This technique is not simply for coating an object; it is for creating high-performance films with precisely engineered properties, such as enhanced durability, specific electrical conductivity, or unique optical characteristics.

The critical insight is that the vacuum itself is the key enabling factor. By removing air and other gases, vacuum deposition creates a pristine, controlled environment that allows for the creation of coatings with a level of purity and structural integrity impossible to achieve in normal atmospheric conditions.

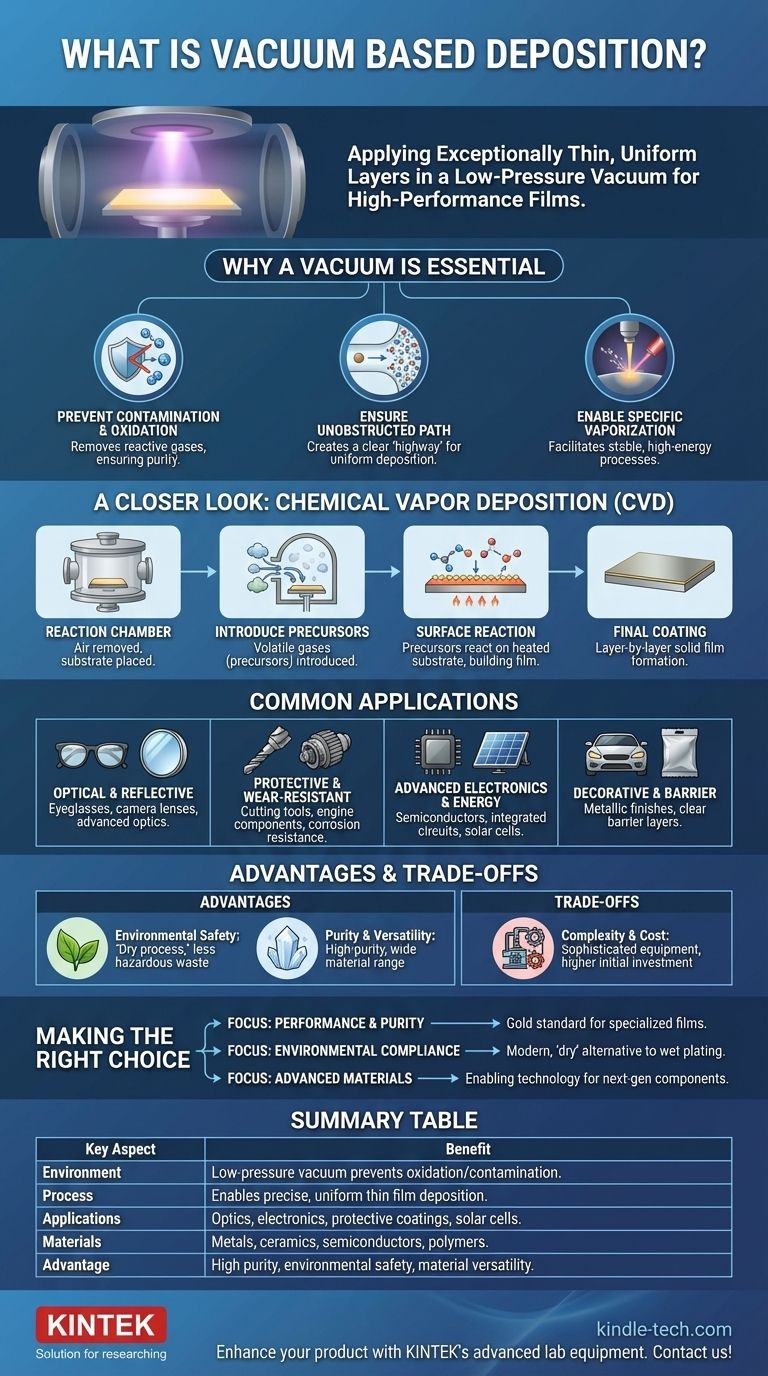

Why a Vacuum is Essential for High-Performance Coatings

The use of a vacuum is not incidental; it is fundamental to the success of the process. It solves three critical problems that would otherwise prevent the formation of a high-quality thin film.

To Prevent Contamination and Oxidation

Most materials, especially when heated to a vapor state, will instantly react with oxygen and other molecules present in the air. This oxidation and contamination would ruin the desired properties of the final coating.

A vacuum chamber removes these reactive gases, ensuring the deposited material remains in its pure form from the source to the substrate.

To Ensure an Unobstructed Path

At normal atmospheric pressure, the air is dense with molecules. Vaporized coating particles would constantly collide with these air molecules, much like trying to run through a dense crowd. Their path, known as the mean free path, would be incredibly short.

The vacuum clears this path, creating a "highway" that allows the vaporized coating material to travel directly to the target surface without interference. This ensures a uniform and consistent film.

To Enable Specific Vaporization Methods

Many of the high-energy techniques used to vaporize solid source materials can only operate effectively in a vacuum. Without it, these processes would be unstable, inefficient, or simply impossible to initiate.

A Closer Look at the Process: Chemical Vapor Deposition (CVD)

While there are many methods, Chemical Vapor Deposition (CVD) is a widely used vacuum-based technique mentioned in industrial applications.

The Reaction Chamber

The process begins by placing the object to be coated, known as the substrate, inside a sealed reaction chamber from which all the air is pumped out.

Introducing Gaseous Precursors

One or more volatile gases, which contain the elements to be deposited, are then introduced into the chamber. These gases are known as precursors.

The Surface Reaction

The substrate is typically heated, causing the precursor gases to react or decompose on its hot surface. This chemical reaction builds up a solid, thin film of the desired material, layer by layer. This method is used to grow materials like carbon nanotubes and deposit a wide range of metallic, ceramic, and semiconducting films.

Common Applications Across Industries

The precision and versatility of vacuum deposition make it indispensable in numerous high-tech and industrial fields.

Optical and Reflective Coatings

This includes everything from anti-reflection coatings on eyeglasses and camera lenses to the highly reflective surfaces of mirrors and the specific interference films used in advanced optical instruments.

Protective and Wear-Resistant Layers

Extremely hard and durable coatings can be applied to cutting tools, engine components, and other industrial parts to dramatically increase their lifespan and resist corrosion. It is a key technology for replacing hazardous materials like cadmium.

Advanced Electronics and Energy

Vacuum deposition is fundamental to manufacturing semiconductor devices, integrated circuits, and solar cells. It's used to lay down the microscopically thin layers of conducting, insulating, and semiconducting materials that make these devices work.

Decorative and Barrier Films

The process is used to create durable, metallic decorative finishes on plastics and metals, often serving as an environmentally safer replacement for traditional electroplating with chromium. It is also used to create clear barrier layers on flexible food packaging to prevent permeation.

Understanding the Advantages and Trade-offs

Choosing any manufacturing process requires weighing its benefits against its inherent complexities.

Advantage: Environmental and Safety Benefits

Vacuum deposition is considered a 'dry process', producing significantly less hazardous waste compared to wet chemical processes like electroplating. This makes it an attractive alternative for replacing toxic materials and meeting strict environmental regulations.

Advantage: Purity and Material Versatility

The vacuum environment ensures an exceptionally high-purity coating, free from the contaminants that plague other methods. It can be used to deposit a vast range of materials, including metals, alloys, ceramics, and polymers.

Consideration: Process Complexity and Cost

The equipment required for vacuum deposition—including vacuum pumps, reaction chambers, and high-energy sources—is sophisticated and expensive. The process requires precise control and expertise, making the initial investment and operational costs higher than some traditional coating methods.

Making the Right Choice for Your Application

The decision to use vacuum deposition hinges entirely on your primary technical and business goals.

- If your primary focus is performance and purity: Vacuum deposition is the gold standard for creating defect-free, highly specialized films for demanding applications in optics, electronics, and aerospace.

- If your primary focus is environmental compliance: This technology offers a 'dry,' modern alternative to hazardous wet-plating processes like chroming or cadmium plating.

- If your primary focus is advanced material development: This is a key enabling technology for manufacturing next-generation components in semiconductors, solar cells, and advanced sensors.

Ultimately, understanding vacuum deposition is understanding how to manipulate matter at a near-atomic level to build superior products from the surface up.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Environment | Low-pressure vacuum prevents oxidation and contamination |

| Process | Enables precise, uniform thin film deposition |

| Applications | Optics, electronics, protective coatings, solar cells |

| Materials | Metals, ceramics, semiconductors, polymers |

| Advantage | High purity, environmental safety, material versatility |

Ready to enhance your product with high-performance thin films?

At KINTEK, we specialize in providing advanced lab equipment and consumables for vacuum deposition processes. Whether you're developing cutting-edge semiconductors, durable protective coatings, or precision optical components, our solutions ensure the purity and performance your applications demand.

Contact us today to discuss how our expertise can support your laboratory's coating and material development needs.

Get in touch with our experts now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating