At its core, a hydraulic press achieves its immense power through a principle known as force multiplication. It uses an incompressible fluid to convert a small force applied to a small area into a massive force exerted over a larger area. This allows a modest input effort to generate an output capable of crushing cars or forging steel.

The fundamental concept is not about creating energy, but trading distance for force. To generate a powerful but short movement in the large piston, you must apply a small force over a much longer distance on the small piston.

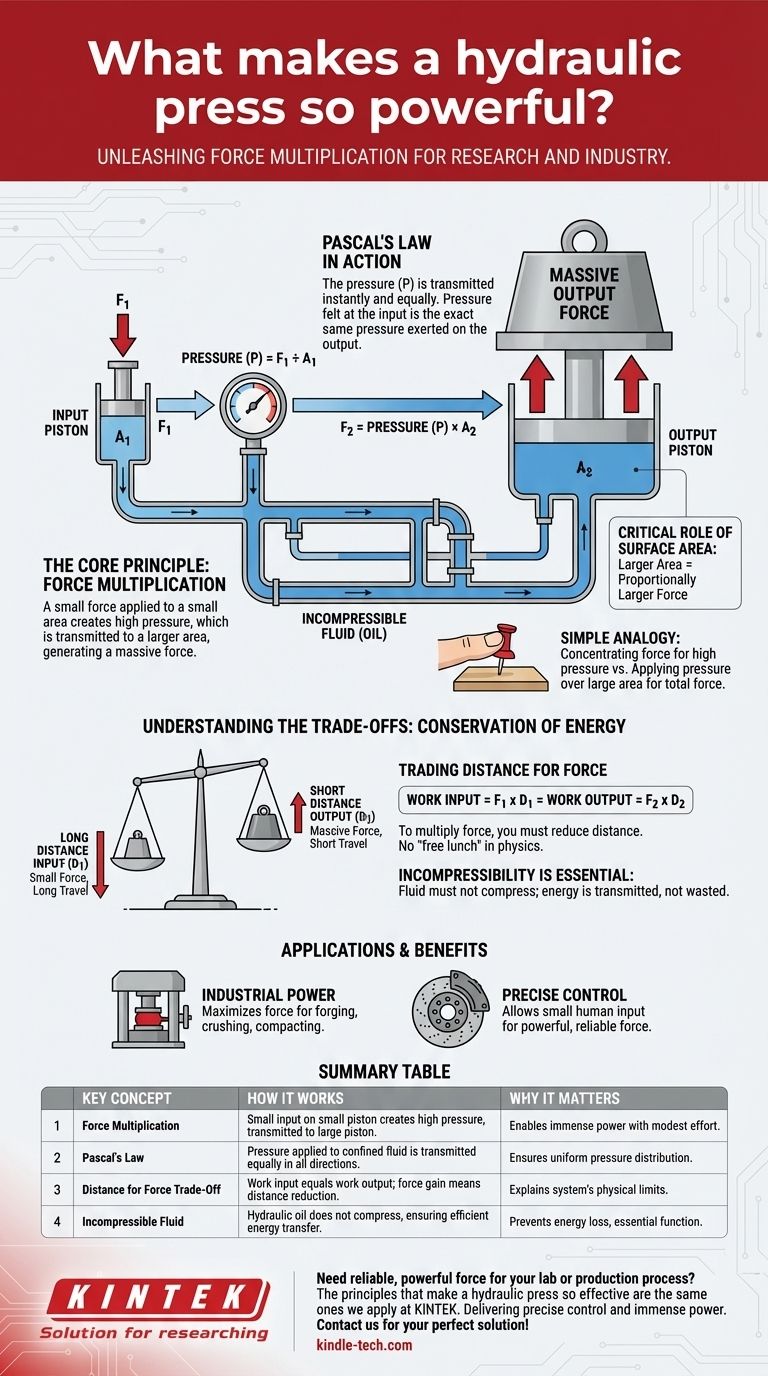

The Core Principle: Force Multiplication

The entire operation of a hydraulic press is governed by a fundamental law of fluid mechanics. Understanding this principle is key to seeing how simple leverage is transformed into incredible power.

It Starts with Pressure

When you apply an initial force to the first, smaller piston (the input piston), you aren't just pushing the fluid. You are creating pressure within the sealed hydraulic system.

Pressure is defined as Force ÷ Area. A small force on a small piston can create surprisingly high internal pressure.

Pascal's Law in Action

The fluid, which is typically an incompressible oil, transmits this pressure instantly and equally to every part of the container. This concept is known as Pascal's Law.

This means the pressure felt at the small input piston is the exact same pressure exerted on the large output piston.

The Critical Role of Surface Area

Here is where the multiplication happens. The output piston has a much larger surface area than the input piston.

Since Force = Pressure x Area, and the pressure is the same on both pistons, the piston with the larger area must produce a proportionally larger force.

A Simple Analogy

Imagine pushing a thumbtack into a board. Your thumb applies a force over the large, flat head. That same force is concentrated onto the tiny, sharp point, creating immense pressure that penetrates the wood.

A hydraulic press works in reverse. It takes a constant pressure and applies it to a very large area (the output piston), generating an immense total force.

Understanding the Trade-offs

The power of a hydraulic press seems almost magical, but it is bound by the laws of physics. There is no "free lunch" in this system; the multiplied force comes at a cost.

The Conservation of Energy

A hydraulic press cannot create more energy than you put into it. The work done on both pistons must remain the same (ignoring minor losses from friction).

Work is calculated as Force x Distance.

Trading Distance for Force

To keep the work equal on both sides, if you multiply the output force by 100 times, you must reduce the distance it travels by 100 times.

This means you have to push the small input piston a very long way (e.g., 100 inches) just to make the large output piston move a short distance (e.g., 1 inch).

Incompressibility is Essential

This entire process relies on the fluid being incompressible. If the fluid could be easily squeezed, the initial input energy would be wasted compressing the fluid itself rather than being transmitted to the output piston. This is why hydraulic systems use specialized oils, not air.

How This Principle is Applied

Understanding force multiplication allows you to see its application in various engineering goals.

- If your primary focus is immense power for industrial processes: Systems like forging presses or car compactors are designed with an enormous difference between the input and output piston areas to maximize force multiplication.

- If your primary focus is precise control with human input: Systems like vehicle brakes or aircraft controls use this principle to allow a small physical effort from a person to apply a powerful and reliable force exactly where it's needed.

The hydraulic press is a masterclass in using fundamental physics to turn a simple push into an unstoppable force.

Summary Table:

| Key Concept | How It Works | Why It Matters |

|---|---|---|

| Force Multiplication | A small input force on a small piston creates high pressure, which is transmitted to a larger piston, generating a massive output force. | Enables tasks requiring immense power, like crushing cars or forging steel, with relatively modest input effort. |

| Pascal's Law | Pressure applied to a confined fluid is transmitted equally in all directions throughout the fluid. | Ensures the pressure created by the small piston is the exact same pressure exerted by the large piston. |

| Trade-Off: Distance for Force | The work input (force x distance) equals work output. A large force gain results in a proportional reduction in the distance the large piston moves. | Explains the physics behind the system; you can't get more energy out than you put in. |

| Incompressible Fluid | Hydraulic oil does not compress, ensuring that the input energy is transmitted efficiently to the output piston. | Prevents energy loss and is essential for the system to function effectively. |

Need reliable, powerful force for your lab or production process? The principles that make a hydraulic press so effective are the same ones we apply at KINTEK. We specialize in robust lab equipment and consumables, delivering the precise control and immense power your operations require. Let our experts help you find the perfect solution for your application. Contact KINTELA today to discuss your specific needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the function of a hydraulic press? A Powerful Solution for Shaping and Forming Materials

- Why is a laboratory hydraulic press required for boron carbide ceramic green bodies? Mastering Precise Pressure Loads

- Which is the most common type of press used in industry? Hydraulic vs. Mechanical

- What is the purpose of the XRF test? Rapid, Non-Destructive Elemental Analysis

- What is the function of an industrial hydraulic press used with steel dies? Achieve High-Density CrFeCuMnNi Compacts

- What PSI should a hydraulic press be? The Answer Lies in Tonnage, Not Just Pressure

- What role does a laboratory hydraulic press play in electrode sheets? Optimize Connectivity & Stability

- How does a laboratory hydraulic press ensure the quality of sulfide electrolyte pellets? Optimize Ion Transport