At its core, a press is made hydraulic by its use of an incompressible fluid, typically oil, to generate immense compressive force. The machine operates on a fundamental principle of fluid mechanics known as Pascal's Law. A pump pressurizes the fluid within a sealed system, and that pressure acts on a piston to produce a powerful, controlled stroke.

The defining characteristic of a hydraulic press is not just its use of fluid, but its ability to achieve massive force multiplication. By applying a small, manageable force to the fluid over a small area, the system generates a significantly larger and more powerful output force over a larger area.

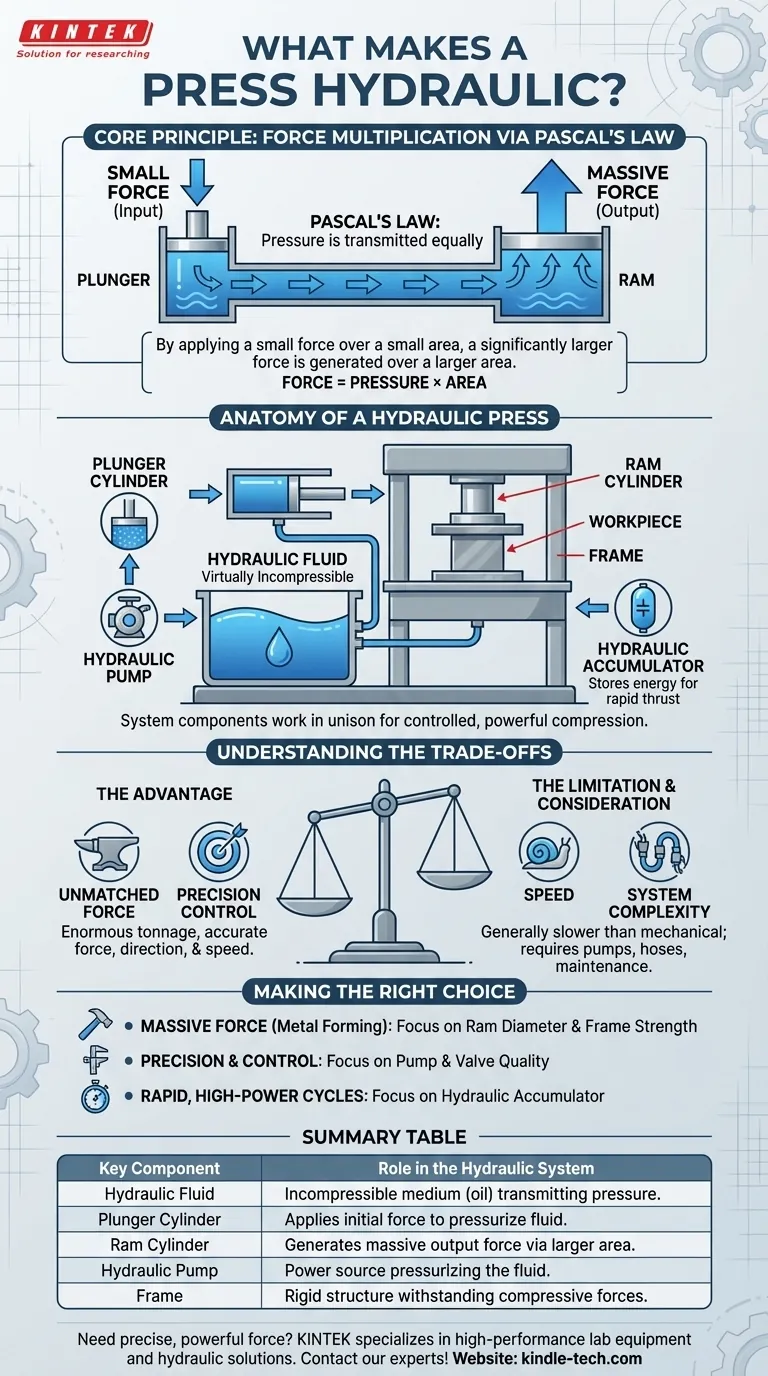

The Core Principle: Pascal's Law Explained

The entire operation of a hydraulic press hinges on a single, elegant concept discovered by Blaise Pascal in the 17th century. Understanding this principle is key to understanding the machine.

What is Pascal's Law?

Pascal's Law states that when pressure is applied to a confined, incompressible fluid, that pressure is transmitted equally and undiminished to every portion of the fluid and the walls of its container.

Imagine squeezing a sealed water bottle. The pressure you apply with your hand isn't just felt where you're squeezing; it's distributed evenly throughout the entire bottle.

How This Creates Force Multiplication

A hydraulic press exploits this law by using two interconnected cylinders of different sizes: a small one called the Plunger and a large one called the Ram.

A small force is applied to the Plunger, which pressurizes the hydraulic fluid. Because that pressure is transmitted equally throughout the system, the same pressure is exerted on the much larger Ram.

Since Force = Pressure × Area, the same pressure acting on the larger surface area of the Ram results in a much greater output force. This is the mechanical advantage that defines the hydraulic press.

Anatomy of a Hydraulic Press

While the principle is simple, a functional press relies on several key components working in unison to apply and control the force.

The Two-Cylinder System

This is the heart of the press. The small Plunger cylinder is where the initial force is applied, and the large Ram cylinder is what delivers the powerful compressive stroke to the workpiece.

The Hydraulic Fluid

Oil is the most common fluid used. It is chosen because it is virtually incompressible, meaning it won't squash under pressure, allowing for efficient force transfer. It also acts as a lubricant for the system's moving parts.

The Power Source

A hydraulic pump is used to pressurize the fluid. It's the engine of the system, creating the initial pressure that the Plunger will then apply to the fluid, starting the force multiplication process.

The Hydraulic Accumulator

In some high-demand systems, an accumulator is included. This device stores high-pressure fluid, acting like a capacitor. It can release this stored energy on demand for a very strong and rapid thrust when needed.

The Frame

The frame is the rigid structure that holds the cylinders and the workpiece. It must be incredibly strong to withstand the immense forces generated by the ram without bending or failing.

Understanding the Trade-offs

Like any technology, hydraulic systems offer distinct advantages but also come with inherent limitations that are important to recognize.

The Advantage: Unmatched Force and Control

Hydraulic presses can generate enormous tonnage with exceptional precision. The force, direction, and speed of the ram can be controlled with a high degree of accuracy by regulating the fluid pressure and flow rate.

The Limitation: Speed

Generally, hydraulic presses are slower than mechanical presses. The time it takes to pump fluid and move the large ram can limit the cycle rate for high-volume, repetitive tasks.

The Consideration: System Complexity

The system requires pumps, high-pressure hoses, valves, and a reservoir for the fluid. This complexity means maintenance is a factor, and fluid leaks can be a potential issue if not properly managed.

Making the Right Choice for Your Goal

The design and focus of a hydraulic press are directly tied to its intended application. Understanding its core components helps you evaluate its suitability for a specific task.

- If your primary focus is massive force for forming metal: The diameter of the ram and the strength of the frame are the key specifications, as they determine the maximum tonnage for forging or stamping.

- If your primary focus is precision and control: The quality of the hydraulic pump and valve system is critical, as these components allow for exact regulation of pressure and ram movement.

- If your primary focus is rapid, high-power cycles: The inclusion of a hydraulic accumulator is essential, as it provides the stored energy needed to deliver powerful strokes without constantly over-tasking the pump.

Ultimately, a hydraulic press masterfully leverages the simple, reliable properties of a confined fluid to transform a small input into an immensely powerful and controllable output.

Summary Table:

| Key Component | Role in the Hydraulic System |

|---|---|

| Hydraulic Fluid | Incompressible medium (like oil) that transmits pressure equally. |

| Plunger Cylinder | Applies initial force to pressurize the fluid. |

| Ram Cylinder | Generates massive output force via pressure acting on a larger area. |

| Hydraulic Pump | Power source that pressurizes the fluid to start the process. |

| Frame | Rigid structure that withstands the immense compressive forces. |

Need precise, powerful force for your lab or production line? KINTEK specializes in high-performance lab equipment, including hydraulic systems designed for reliability and control. Our expertise ensures you get the right press for your specific application, whether it's for material testing, forming, or R&D. Contact our experts today to discuss how a KINTEK hydraulic solution can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System