The immense power of a hydraulic press is derived directly from the materials used in its construction. It is primarily built from high-strength steel for its frame to contain enormous pressure, while its core hydraulic system relies on precisely machined cylinders, pistons, and high-performance seals to generate and transmit force without failure.

The material choices for a hydraulic press are a direct reflection of its function. The fundamental principle is using rigid, non-deforming steel for the structural frame and wear-resistant, precisely engineered components for the hydraulic system to ensure safety, longevity, and the reliable transmission of force.

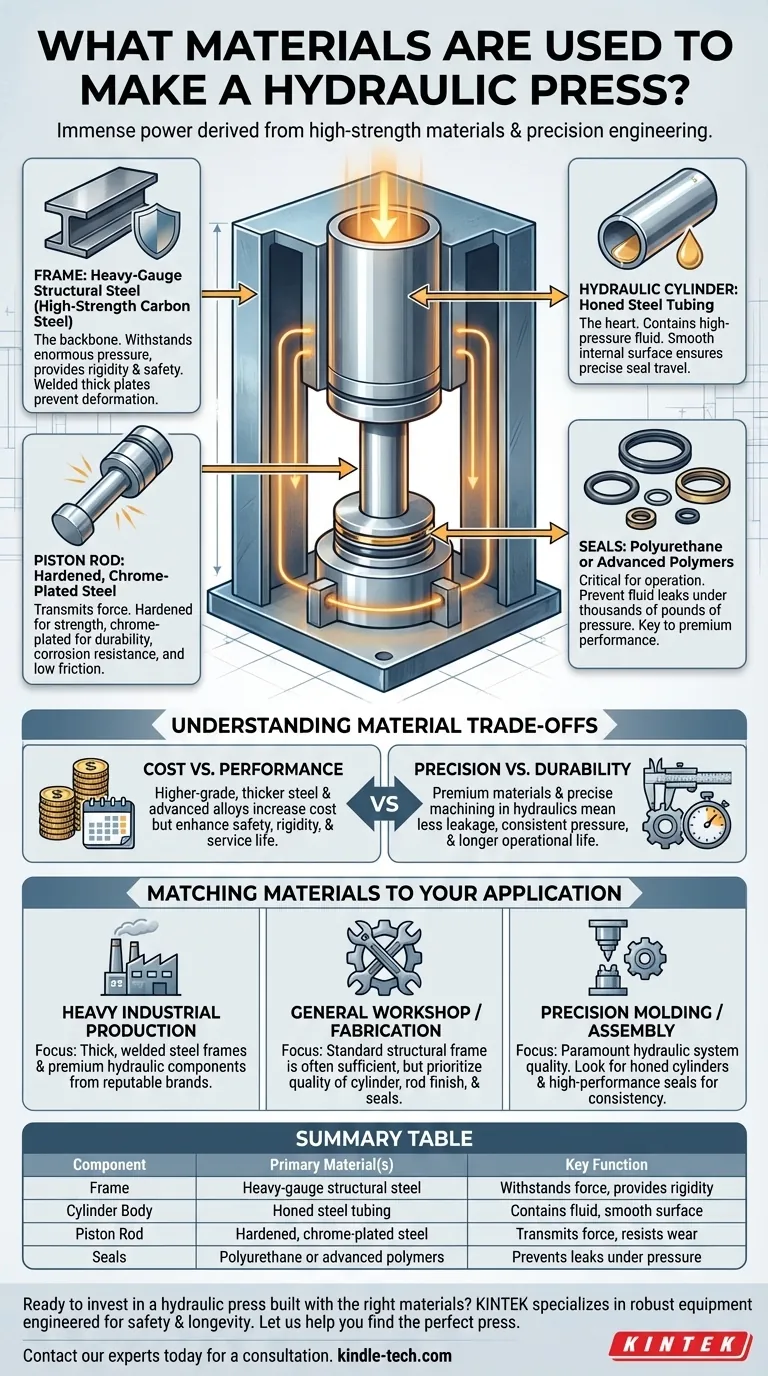

The Anatomy of a Press: Key Components and Materials

A hydraulic press is a system where each component's material is chosen specifically for the role it plays in generating and containing force.

The Frame: The Foundation of Strength

The frame is the backbone of the press, responsible for withstanding the immense force generated by the hydraulic system.

The primary material for the frame is heavy-gauge structural steel, often high-strength carbon steel. It is used in thick plates that are welded together to create an exceptionally rigid structure that will not deform under load.

The Hydraulic Cylinder: The Heart of the Machine

The hydraulic cylinder is where the fluid pressure is converted into mechanical force. Its materials must handle high pressure and constant movement.

The cylinder body itself is typically made from honed steel tubing. The honing process creates an extremely smooth and precise internal surface for the piston seals to travel against, preventing leaks.

The piston rod, which extends from the cylinder to press the workpiece, is made from hardened, chrome-plated steel. The hardening provides strength, while the chrome plating offers a durable, corrosion-resistant, and low-friction surface.

The Hydraulic System: Seals and Fluid

While less visible, the smaller components of the hydraulic system are critical for its operation and longevity.

High-performance seals are arguably one of the most crucial components. They are typically made from durable elastomers like polyurethane or other advanced polymers designed to prevent fluid leaks under thousands of pounds of pressure.

The quality of these seals is often what distinguishes premium hydraulic systems, such as those from brands like Rexroth mentioned in industry literature.

Understanding the Trade-offs in Material Selection

The specific grade and quality of materials used in a press directly impact its performance, lifespan, and cost.

Cost vs. Performance

Higher-grade, thicker steel and advanced alloys for the frame increase the machine's cost but also significantly enhance its safety, rigidity, and service life.

Less expensive presses may use thinner or lower-grade steel, making them susceptible to frame flex or fatigue over time, especially when used at their maximum rated tonnage.

Precision vs. Durability

The material science behind the hydraulic components is a key differentiator. Premium brands use superior materials for seals and more precise machining on cylinders and pistons.

This results in less internal leakage, more consistent pressure application, and a longer operational life before requiring a rebuild. Cheaper components may fail or wear out sooner, leading to downtime and inconsistent performance.

Matching Materials to Your Application

Choosing a press requires looking beyond the tonnage rating and considering how its materials align with your work.

- If your primary focus is heavy industrial production: Prioritize presses with thick, welded steel plate frames and premium hydraulic components from reputable brands known for their durability.

- If your primary focus is general workshop or fabrication use: A press with a standard structural steel frame is often sufficient, but pay close attention to the quality of the hydraulic cylinder, rod finish, and seals.

- If your primary focus is precision molding or assembly: The quality of the hydraulic system is paramount. Look for evidence of precision-honed cylinders and high-performance seals to ensure consistent and repeatable pressure.

Ultimately, understanding the materials used in a hydraulic press empowers you to assess the true quality, safety, and long-term value of the machine.

Summary Table:

| Component | Primary Material(s) | Key Function |

|---|---|---|

| Frame | Heavy-gauge structural steel (carbon steel) | Withstands immense force, provides rigidity and safety |

| Cylinder Body | Honed steel tubing | Contains high-pressure fluid, provides a smooth surface for seals |

| Piston Rod | Hardened, chrome-plated steel | Transmits force, resists wear and corrosion |

| Seals | Polyurethane or advanced polymers | Prevents fluid leaks under extreme pressure |

Ready to invest in a hydraulic press built with the right materials for your specific needs?

At KINTEK, we specialize in providing robust laboratory and industrial equipment. Our hydraulic presses are engineered with high-quality materials to ensure safety, longevity, and reliable performance for your pressing, molding, or fabrication tasks.

Let us help you find the perfect press for your application. Contact our experts today for a personalized consultation and discover the KINTEK difference in quality and support.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Lab Heat Press

People Also Ask

- What is the purpose of a laboratory hydraulic press for LATP electrolyte pellets? Achieve Optimal Density & Conductivity

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!