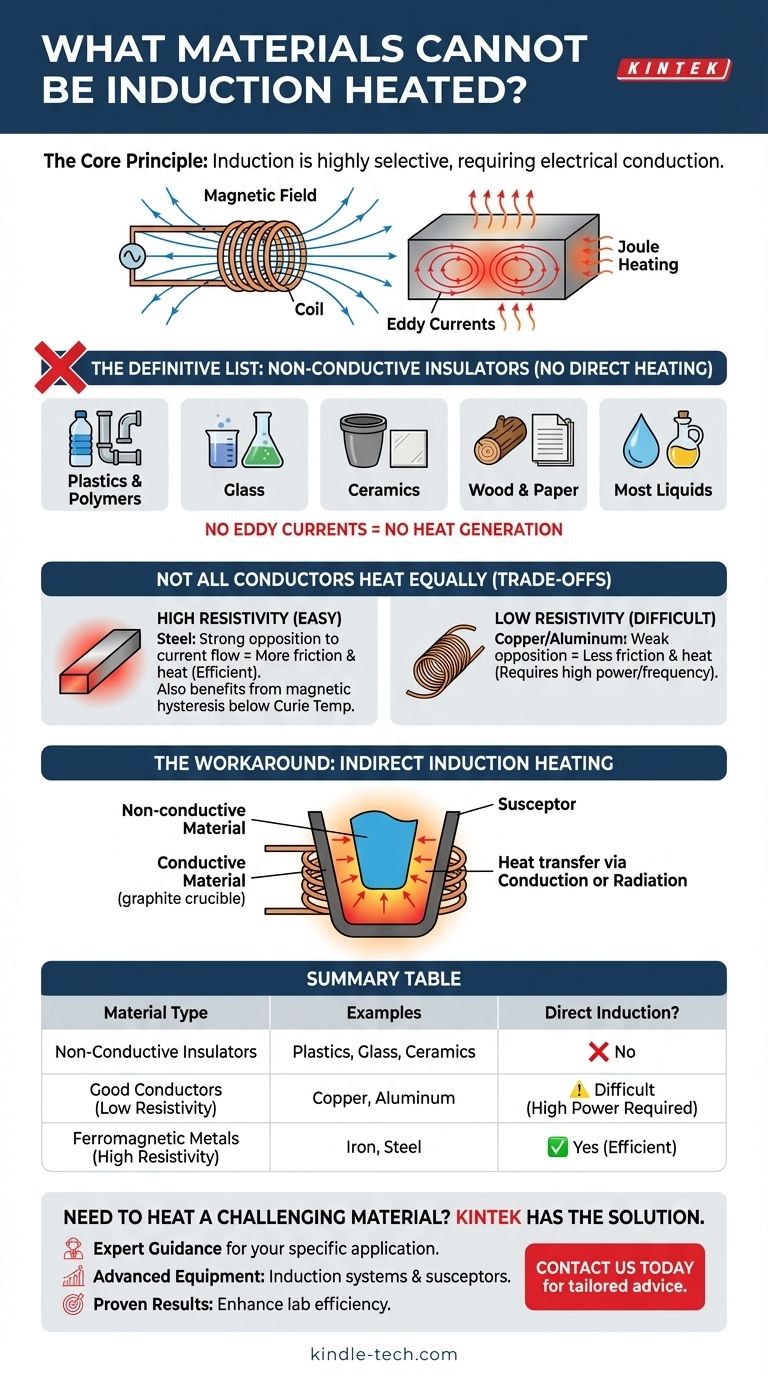

At its core, induction heating is a highly selective process. It cannot be used to directly heat materials that are poor electrical conductors. This means common materials like plastics, glass, ceramics, wood, and paper will not heat up when placed in an induction field.

Induction heating relies on generating electrical eddy currents within a material itself. If a material cannot conduct electricity, it lacks the pathway for these currents to flow, rendering direct induction impossible.

The Fundamental Principle: Why Conduction is Key

To understand which materials are incompatible, we must first understand how induction works. The entire process depends on a material's ability to conduct electricity.

The Magnetic Field

An induction system uses a coil of wire through which a high-frequency alternating current (AC) is passed. This creates a rapidly changing magnetic field around the coil.

Inducing Eddy Currents

When an electrically conductive material is placed inside this magnetic field, the field induces circulating electrical currents within the material. These are known as eddy currents.

Resistance Creates Heat

The material's natural resistance to the flow of these eddy currents generates friction and, therefore, intense heat. This is known as Joule heating. Without conductivity, no eddy currents can form, and no heat is generated.

The Definitive List: Materials That Cannot Be Heated

The primary reason a material cannot be induction heated is its lack of electrical conductivity. The free electrons found in metals simply aren't present in these materials.

Non-Conductive Insulators

These materials are electrical insulators and will not respond to an induction field.

- Plastics & Polymers (e.g., Polyethylene, PVC, Teflon)

- Glass

- Ceramics (e.g., Alumina, Zirconia)

- Wood & Paper

- Most liquids (e.g., pure water, oils)

Understanding the Trade-offs: Not All Conductors Heat Equally

Simply being a metal does not guarantee efficient induction heating. Two key properties, resistivity and permeability, dictate how well a material will heat.

The Role of Resistivity

Resistivity is a measure of how strongly a material opposes the flow of electric current. Higher resistivity leads to more friction and thus more heat.

This is why steel, which has high resistivity, heats very easily. In contrast, copper, which has very low resistivity, is an excellent conductor and is much more difficult to heat with induction.

The Impact of Magnetic Properties

Magnetic materials like iron and certain steels are far easier to heat than non-magnetic ones. This is because they also generate heat through a process called hysteresis loss.

This secondary heating effect, however, disappears when the metal is heated past its Curie temperature, at which point it loses its magnetic properties.

The Workaround: Indirect Induction Heating

If your goal is to heat a non-conductive material, you are not entirely out of options. The solution is to heat it indirectly.

Using a Conductive "Susceptor"

This involves placing the non-conductive material into a conductive container, such as a graphite crucible or a metal vessel.

The induction field heats the conductive container (the susceptor), and that heat is then transferred to the non-conductive material through conduction or radiation. A common example is cooking food (non-conductive) in a metal pan on an induction cooktop.

Making the Right Choice for Your Goal

Selecting your approach depends entirely on the material you need to heat.

- If your primary focus is heating conductive metals like steel: Direct induction is the most rapid, precise, and efficient method available.

- If your primary focus is heating non-conductive materials like ceramics or polymers: Direct induction is not an option; you must use an indirect method by heating a conductive susceptor.

- If your primary focus is heating highly conductive metals like copper or aluminum: Be prepared for a challenge, as you will require higher frequencies and significantly more power to achieve effective heating.

Ultimately, mastering induction heating is about understanding the electrical properties of your target material.

Summary Table:

| Material Type | Examples | Can Be Directly Induction Heated? |

|---|---|---|

| Non-Conductive Insulators | Plastics, Glass, Ceramics, Wood | ❌ No |

| Good Conductors (Low Resistivity) | Copper, Aluminum | ⚠️ Difficult (requires high power/frequency) |

| Ferromagnetic Metals (High Resistivity) | Iron, Steel | ✅ Yes (heats very efficiently) |

Need to heat a challenging material? KINTEK has the solution.

Whether you're working with highly conductive metals like copper or non-conductive materials like ceramics, our expertise in lab equipment and consumables ensures you get the right setup for efficient and precise heating.

Let us help you optimize your process:

- Expert Guidance: Get tailored advice for your specific material and application.

- Advanced Equipment: Access industry-leading induction heating systems and susceptors for indirect heating.

- Proven Results: Enhance your lab's efficiency with reliable, high-performance solutions.

Contact us today via our contact form to discuss your project and discover how KINTEK can meet your laboratory heating needs.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Anti-Cracking Press Mold for Lab Use

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

People Also Ask

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance