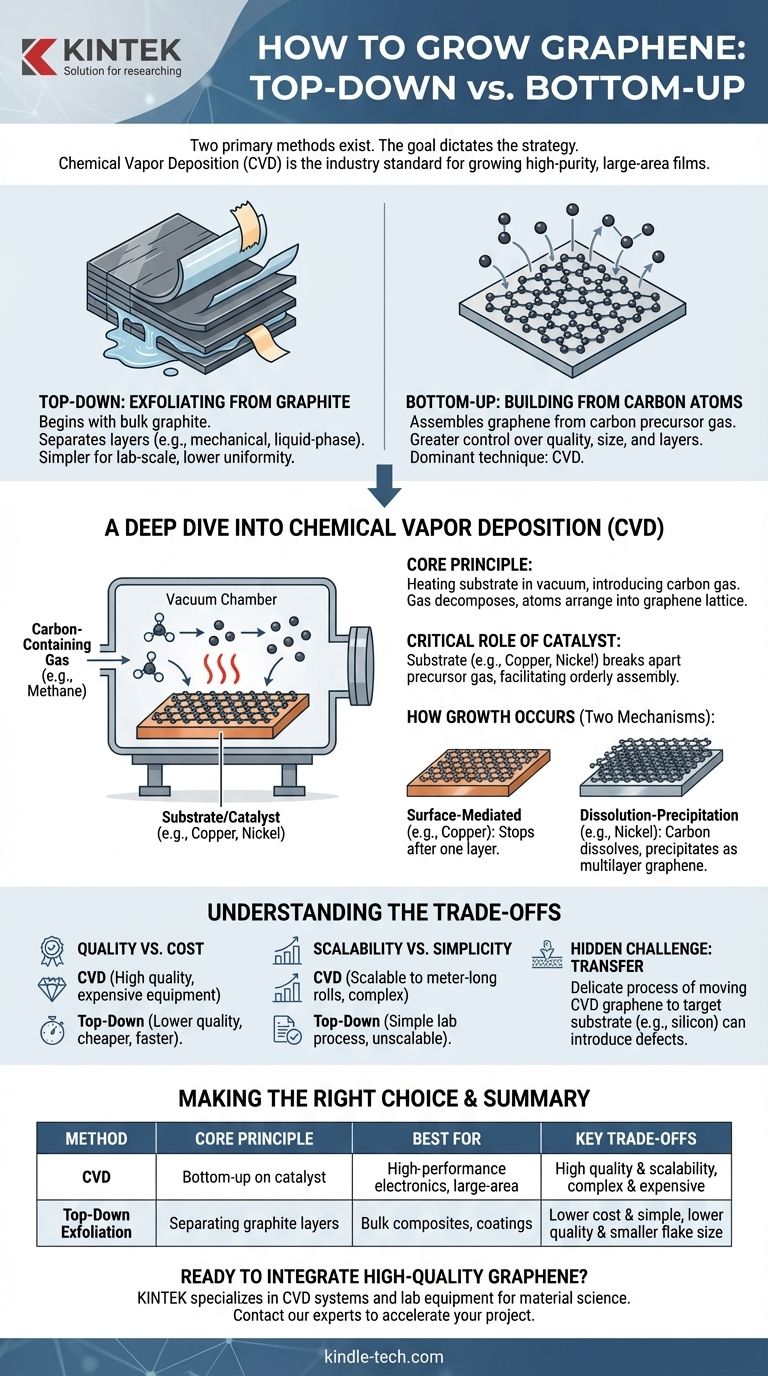

The primary methods for producing graphene fall into two categories: 'top-down' approaches that start with graphite and 'bottom-up' approaches that build the material atom by atom. The most prevalent and powerful method for growing large, high-quality sheets of graphene is a bottom-up technique called Chemical Vapor Deposition (CVD).

While several methods exist to produce graphene, the choice is not arbitrary. The underlying goal—whether for advanced electronics or bulk composites—dictates the most effective strategy, with Chemical Vapor Deposition (CVD) being the industry standard for growing high-purity, large-area films.

The Two Fundamental Approaches: Top-Down vs. Bottom-Up

To understand how graphene is grown, it is essential to distinguish between the two core philosophies of its creation.

Top-Down: Exfoliating from Graphite

This approach begins with bulk graphite, which is essentially a stack of countless graphene layers. The goal is to separate, or exfoliate, these layers.

Methods like mechanical exfoliation (the "Scotch tape method") or liquid-phase exfoliation are simpler for lab-scale work but often result in smaller, multi-layered flakes with less structural uniformity.

Bottom-Up: Building from Carbon Atoms

This is the true "growth" method. It involves assembling graphene from individual carbon atoms sourced from a precursor gas.

This approach offers far greater control over the final product's quality, size, and number of layers. The dominant technique in this category is Chemical Vapor Deposition (CVD).

A Deep Dive into Chemical Vapor Deposition (CVD)

CVD is popular because it reliably produces high-quality, large-area graphene films suitable for demanding applications like electronics and sensors.

The Core Principle of CVD

The process involves heating a substrate material within a vacuum chamber and introducing a carbon-containing gas, such as methane.

At high temperatures, the gas decomposes, freeing carbon atoms that then arrange themselves on the surface of the substrate into the characteristic hexagonal lattice of graphene.

The Critical Role of the Catalyst

The substrate is not merely a surface; it's an active catalyst. Transition metals like copper and nickel are commonly used.

These metals are cost-effective and efficiently break apart the precursor gas molecules, facilitating the orderly assembly of carbon atoms into a single, uniform layer.

How Growth Occurs

The specific growth mechanism depends on the catalyst. On metals with low carbon solubility (like copper), growth is surface-mediated, naturally stopping after a single complete layer is formed.

On metals with high carbon solubility (like nickel), a dissolution-precipitation mechanism occurs. Carbon atoms dissolve into the hot metal and then precipitate out as graphene layers upon cooling, which allows for the controlled growth of multilayer graphene.

Controlling the Final Product

The key factors in any CVD process are the catalyst, conditions, and atmosphere. By precisely controlling the temperature, pressure, and flow of gases, technicians can dictate the quality, thickness, and domain size of the resulting graphene sheet.

Understanding the Trade-offs

No single method is universally superior; each comes with inherent compromises that make it suitable for different purposes.

Quality vs. Cost

CVD produces the highest quality, single-layer graphene, which is essential for electronics. However, it requires specialized, expensive equipment.

Top-down exfoliation is often cheaper and faster for producing large volumes of graphene flakes, but the quality and consistency are much lower, making it suitable for applications like composites or inks.

Scalability vs. Simplicity

CVD has been demonstrated on an industrial scale, producing meter-long rolls of graphene film. The process, however, remains complex.

Mechanical exfoliation is simple enough to be done in any lab but is fundamentally unscalable for mass production of large films.

The Hidden Challenge: Transfer

A critical, often overlooked, step in the CVD process is transferring the grown graphene from its metal catalyst onto a target substrate (like silicon or plastic).

This delicate transfer process is a major source of potential defects, wrinkles, and contamination that can compromise the material's exceptional properties.

Making the Right Choice for Your Application

Your choice of production method is dictated entirely by your end goal and performance requirements.

- If your primary focus is high-performance electronics or fundamental research: CVD is the required standard, as it is the only method that can grow large-area, high-purity, single-layer films.

- If your primary focus is creating bulk composites, coatings, or conductive inks: Top-down exfoliation methods are often more cost-effective and sufficient for producing the necessary volume of graphene flakes.

- If your primary focus is fabricating controlled multi-layer graphene: The CVD process, especially using the dissolution-precipitation mechanism on catalysts like nickel, offers the most precise control.

Ultimately, understanding the principles behind each method empowers you to select the most effective path from raw carbon to a truly functional material.

Summary Table:

| Method | Core Principle | Best For | Key Trade-offs |

|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Bottom-up growth from carbon gas on a catalyst (e.g., copper, nickel) | High-performance electronics, sensors, large-area films | Highest quality & scalability, but complex process & expensive equipment |

| Top-Down Exfoliation | Separating layers from bulk graphite (e.g., Scotch tape method) | Bulk composites, conductive inks, coatings | Lower cost & simpler, but lower quality & smaller flake size |

Ready to Integrate High-Quality Graphene into Your Research or Production?

Choosing the right production method is critical for your application's success. KINTEK specializes in providing the advanced lab equipment and consumables needed for cutting-edge material science, including Chemical Vapor Deposition (CVD) systems for growing superior graphene.

We serve laboratories and research institutions focused on developing next-generation electronics, sensors, and composite materials. Let us help you achieve precise control over your graphene's quality, thickness, and size.

Contact our experts today to discuss how our solutions can accelerate your project from raw carbon to a functional, high-performance material.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating