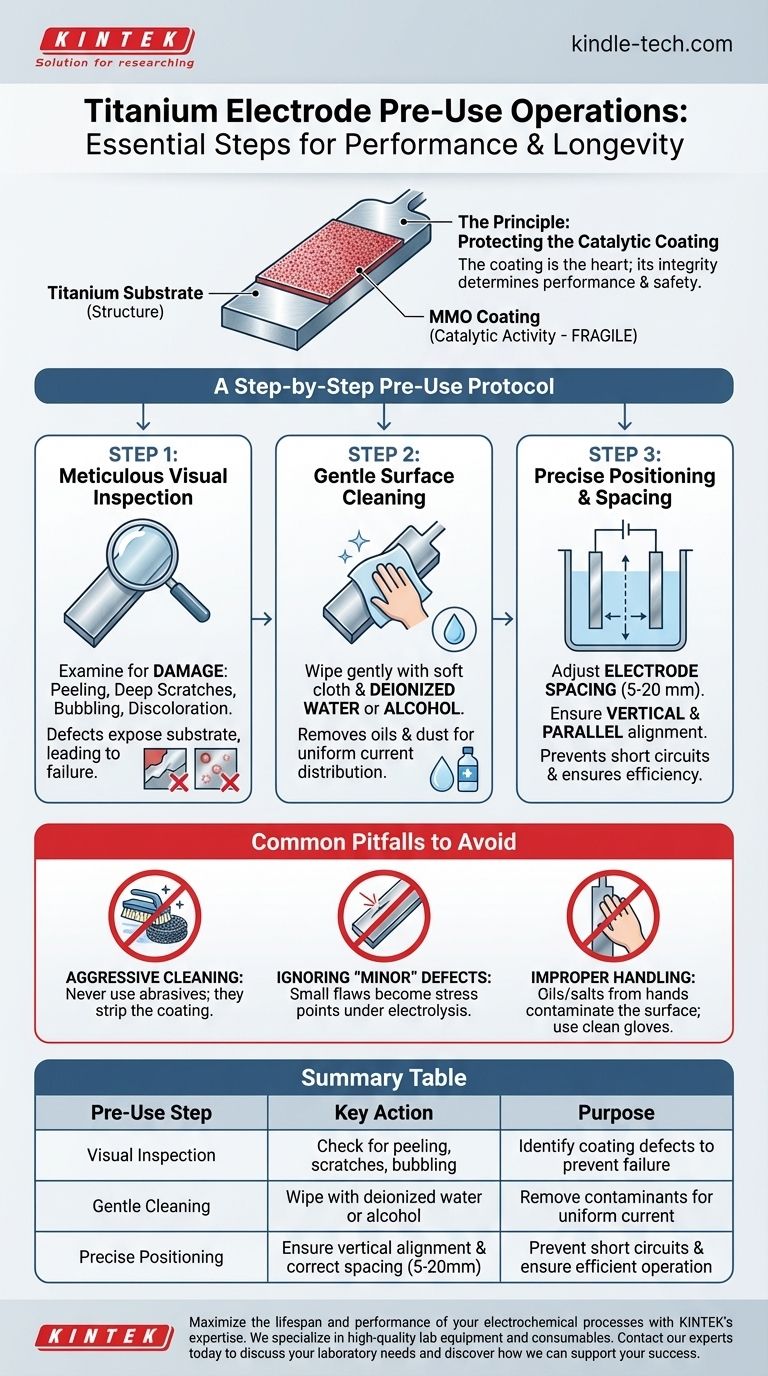

Before use, every titanium electrode requires three critical operations: a thorough visual inspection of the coating, a gentle cleaning with deionized water or alcohol, and precise positioning within the electrolytic cell. These steps are not mere formalities; they are essential for ensuring operational safety, process efficiency, and the longevity of the electrode's vital catalytic coating.

The core purpose of pre-use preparation is to protect the fragile, active coating on the titanium substrate. This coating is the functional heart of the electrode, and its integrity directly determines performance, safety, and lifespan.

The Principle: Protecting the Catalytic Coating

A titanium electrode's value comes from its surface coating, typically a mixed metal oxide (MMO). This thin layer is where the electrochemical reactions occur.

The underlying titanium provides structural integrity and corrosion resistance, but the coating provides the catalytic activity. Any damage to this layer compromises the entire electrode.

Therefore, all handling and preparation procedures are designed to preserve this delicate surface.

A Step-by-Step Pre-Use Protocol

Follow this sequence rigorously before introducing any electrode into service.

Step 1: Meticulous Visual Inspection

Before anything else, carefully examine the entire coated surface.

Look for any signs of damage or imperfection, such as peeling, deep scratches, bubbling, or significant discoloration.

These defects can expose the underlying titanium substrate, creating points of failure that can lead to rapid degradation or passivation once a current is applied.

Step 2: Gentle Surface Cleaning

The goal is to remove contaminants without causing mechanical damage.

Wipe the coating surface gently using a soft cloth with deionized water or alcohol. This removes residual oils, dust, or fingerprints left from handling.

These contaminants can cause uneven current distribution, leading to localized overheating and premature failure of the coating.

Step 3: Precise Positioning and Spacing

Proper placement within the electrolytic cell is critical for both safety and performance.

Adjust the electrode spacing according to your cell's design, typically between 5 mm and 20 mm.

Ensure the electrodes hang perfectly vertically and parallel to one another. Any tilting or misalignment dramatically increases the risk of a short circuit, which can destroy both the electrodes and the power supply.

Common Pitfalls to Avoid

Mistakes during preparation are a primary cause of premature electrode failure.

Aggressive Cleaning Methods

Never use steel wool, abrasive pads, or hard tools to clean the electrode surface.

These materials will scratch and strip away the thin catalytic coating, rendering the electrode useless. Damage of this type is irreversible.

Ignoring "Minor" Defects

Do not dismiss small scratches or bubbles as insignificant.

Under the harsh conditions of electrolysis, these minor flaws become concentration points for electrical and chemical stress, accelerating the degradation of the surrounding coating.

Improper Handling

Always handle electrodes with clean gloves when possible.

Oils and salts from your hands can contaminate the active surface, potentially interfering with the electrochemical process and creating "blind spots" on the coating.

Making the Right Choice for Your Goal

Your preparation focus should align with your operational priorities.

- If your primary focus is maximizing electrode lifespan: The meticulous visual inspection is your most critical step to prevent introducing a compromised electrode into service.

- If your primary focus is ensuring process consistency: Gentle, thorough cleaning is key to providing a uniform surface for predictable and repeatable electrochemical results.

- If your primary focus is operational safety: Precise vertical alignment and correct spacing are non-negotiable to prevent catastrophic short circuits.

Ultimately, diligent preparation is the foundation for reliable and long-lasting electrode performance.

Summary Table:

| Pre-Use Step | Key Action | Purpose |

|---|---|---|

| Visual Inspection | Check for peeling, scratches, bubbling | Identify coating defects to prevent failure |

| Gentle Cleaning | Wipe with deionized water or alcohol | Remove contaminants for uniform current distribution |

| Precise Positioning | Ensure vertical alignment and correct spacing (5-20mm) | Prevent short circuits and ensure efficient operation |

Maximize the lifespan and performance of your electrochemical processes with KINTEK's expertise. Proper electrode preparation is just the beginning. KINTEK specializes in high-quality lab equipment and consumables, including electrodes designed for durability and consistent results. Our team can help you select the right equipment and provide guidance on best practices to ensure your lab operates safely and efficiently.

Contact our experts today to discuss your specific laboratory needs and discover how we can support your success.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

People Also Ask

- What are the properties of graphite at high temperatures? Unlock Its Strength and Stability in Extreme Heat

- What is the thermal conductivity of graphite at high temperatures? A Guide to Thermal Management in Extreme Heat

- Why does graphite have a high melting point? The Power of Its Giant Covalent Structure

- How should contamination of a gold plate electrode be prevented and managed? Essential Care for Reliable Data

- Why are platinum or graphite used as cathodes in PEO for Zircaloy-4? Achieve High-Purity Coatings Today

- What is the primary function of high-purity graphite electrodes in AC leaching? Powering Efficient Metal Recovery

- What are the advantages of using Dimensionally Stable Anodes (DSA)? Enhance Reactor Efficiency and Durability

- Why is glassy carbon selected for mediator-assisted indirect oxidation of glycerol? The Key to Unbiased Research