To ensure accurate and repeatable results in FTIR spectroscopy, the most critical precautions are protecting the instrument's sensitive optics from moisture and contamination, meticulously preparing your sample, and performing a clean, representative background scan immediately before analyzing your sample. These steps are fundamental to preventing instrument damage and acquiring a spectrum that reflects your material, not your environment or a procedural error.

The reliability of any FTIR spectrum is built on a foundation of preventative care. Success depends less on the final measurement and more on the meticulous steps taken beforehand to protect the fragile optics and eliminate atmospheric and sample-related interference.

Protecting the Spectrometer's Core Components

The heart of an FTIR spectrometer contains optical components that are highly effective at transmitting infrared light but are also uniquely vulnerable to environmental conditions.

The Critical Role of Infrared Optics

Many FTIR components, such as windows, beam splitters, and sample holders (like KBr pellets), are made from alkali halide salts (e.g., Potassium Bromide - KBr, Sodium Chloride - NaCl). These materials are used because they are transparent to IR radiation and do not create interfering signals.

Why Moisture is the Primary Enemy

These salt-based optics are hygroscopic, meaning they readily absorb moisture from the air. Even brief exposure to high humidity can cause the crystal surfaces to fog, etch, or even dissolve over time, severely degrading the instrument's performance.

Handling Optics and Sample Holders

You should never touch optical components with your bare hands. Oils and moisture from your skin will contaminate and damage their surfaces. Always use powder-free gloves and handle windows or pellets by their edges.

Proper Storage and Environment

To prevent moisture damage, the optical components within the spectrometer are often housed in a sealed and desiccated compartment. Sample preparation materials like KBr powder should be stored in a desiccator and dried in an oven before use to remove absorbed water. For high-precision work, the sample chamber is often purged with a dry, inert gas like nitrogen to displace water vapor and carbon dioxide.

Avoiding Contamination for Accurate Spectra

An FTIR spectrum is incredibly sensitive. Its purpose is to detect molecular vibrations, and it will just as easily detect vibrations from contaminants as it will from your sample.

The Problem of Atmospheric Interference

Gases in the ambient air have distinct infrared absorption bands. Carbon dioxide (CO₂) and water (H₂O) vapor are the most significant culprits. Their presence can create sharp, interfering peaks in your spectrum, potentially obscuring important signals from your sample.

The Importance of the Background Scan

Before running a sample, you must perform a background scan. This measures the spectrum of the ambient environment (including the CO₂ and H₂O) and any signal from the empty sample holder. The instrument then automatically subtracts this background from your sample's spectrum.

It is crucial to run the background scan immediately before the sample scan under identical conditions. A delay can allow atmospheric conditions to change, leading to poor subtraction and false peaks in the final spectrum.

Preventing Sample Cross-Contamination

Always ensure your sample preparation tools (spatulas, mortar and pestle) and sample holders (ATR crystal, salt plates) are impeccably clean. Residue from a previous sample will contaminate your current one, leading to a composite spectrum that is impossible to interpret correctly.

Common Pitfalls in Sample Preparation

The majority of poor FTIR results can be traced back to improper sample preparation. This is where attention to detail is paramount.

For KBr Pellets: The "Cloudy Pellet" Problem

When preparing a solid sample in a KBr pellet, a cloudy or opaque appearance is a common issue. This is almost always caused by moisture in the KBr powder or by KBr particles that are not ground finely enough to prevent light scattering.

For KBr Pellets: Incorrect Sample Concentration

The amount of sample mixed with the KBr powder is critical. Too much sample will cause the strongest absorption bands to become "flat-topped" (total absorbance), losing all quantitative information. Too little sample will result in a weak, noisy spectrum where key features may be missed.

For ATR-FTIR: Ensuring Good Contact

Attenuated Total Reflectance (ATR) is a popular technique that measures the surface of a sample. Its effectiveness depends entirely on achieving firm, uniform contact between the sample and the ATR crystal (often diamond or zinc selenide). Any air gaps will severely weaken or eliminate the IR signal, resulting in a poor-quality spectrum.

A Practical Checklist for Reliable Results

Your approach should be guided by the goal of your analysis. Use these principles to establish a robust workflow.

- If your primary focus is high-precision quantitative analysis: You must purge the sample chamber with dry nitrogen or air to create a stable, interference-free atmosphere for both background and sample scans.

- If your primary focus is routine qualitative identification: A fresh background scan immediately before each sample is your most important tool for mitigating atmospheric changes.

- If you are preparing KBr pellets: Always use dry KBr powder stored in a desiccator and ensure your final pellet is transparent and glass-like for the best results.

- If you are using an ATR accessory: Clean the crystal meticulously before each measurement and apply sufficient pressure to ensure complete contact between the sample and the crystal surface.

Ultimately, treating the instrument and your sample with meticulous care is the single most important factor in acquiring trustworthy spectroscopic data.

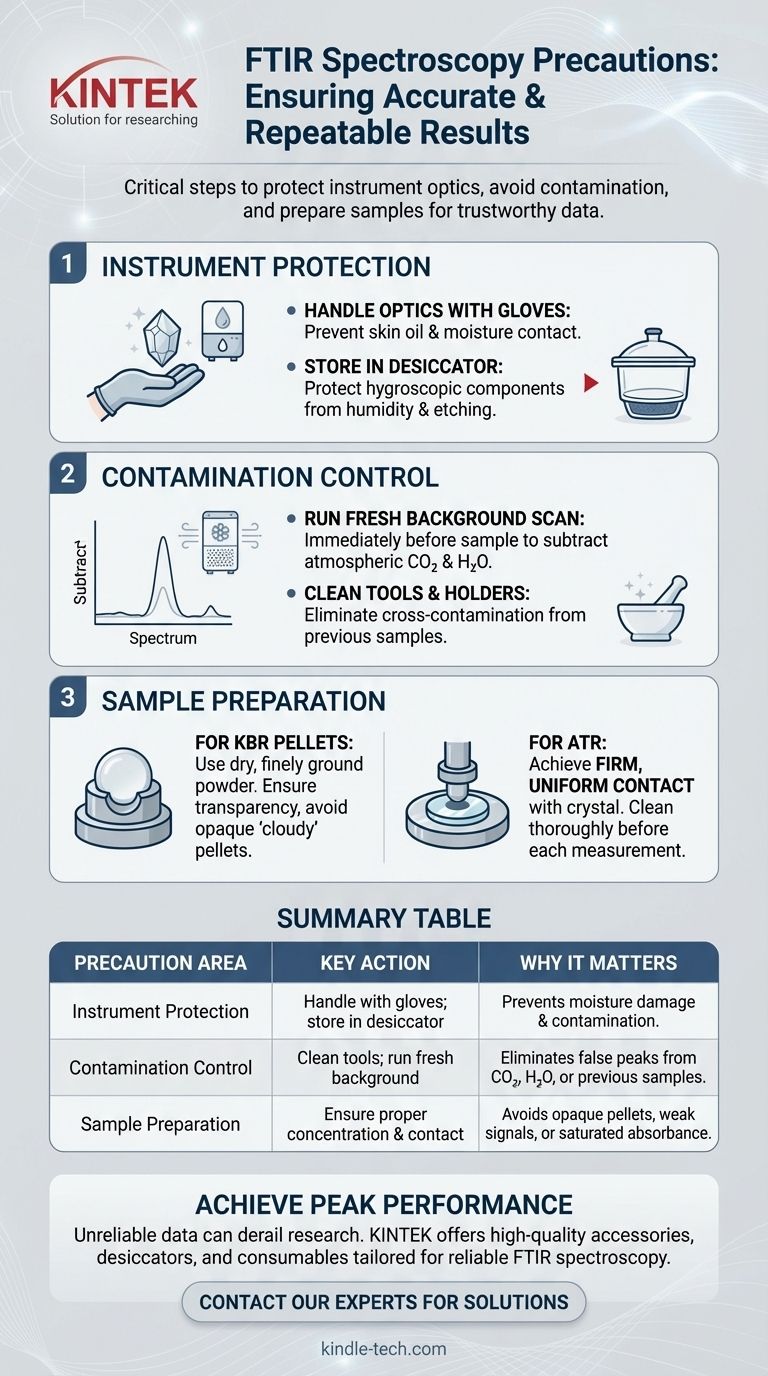

Summary Table:

| Precaution Area | Key Action | Why It Matters |

|---|---|---|

| Instrument Protection | Handle optics with gloves; store in desiccator | Prevents moisture damage & contamination of hygroscopic components |

| Contamination Control | Clean tools & holders; run fresh background scans | Eliminates false peaks from CO₂, H₂O, or previous samples |

| Sample Preparation | Ensure proper sample concentration & contact (e.g., clear KBr pellets, firm ATR contact) | Avoids opaque pellets, weak signals, or saturated absorbance |

Achieve Peak Performance in Your Lab

Unreliable FTIR data can derail your research and quality control. KINTEK specializes in providing high-quality lab equipment and consumables tailored for spectroscopy. Our range includes durable FTIR accessories, desiccators for proper storage, and pure KBr powders to ensure your sample preparation is flawless.

Let us help you enhance accuracy and efficiency in your laboratory workflows.

Contact our experts today to discuss your specific FTIR needs and discover the right solutions for reliable, repeatable results.

Visual Guide

Related Products

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Three-dimensional electromagnetic sieving instrument

- Infrared High Resistance Single Crystal Silicon Lens

- Infrared Thermal Imaging Temperature Measurement Double-Sided Coated Germanium Ge Lens

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How is temperature tracking managed in Ultra Freezers? From Basic Charts to Smart Alerts

- What are the effects of pyrolysis on biomass? A Tunable Process for Biochar, Bio-oil, and Syngas

- What roles do bed materials play in biomass gasification? Optimizing Heat Transfer and Chemical Stability

- What is the difference between thick film and thin film PCB? Choosing the Right Circuit Technology

- What does HIP process do? Eliminate Porosity for Superior Material Performance

- What is the role of ultrasonic cleaning equipment in the surface modification of biomedical materials? Boost Adhesion

- Why pyrolysis is better than incineration? Transforming Waste into Valuable Resources

- What is a general purpose laboratory oven? A Guide to Drying, Sterilizing, and Curing