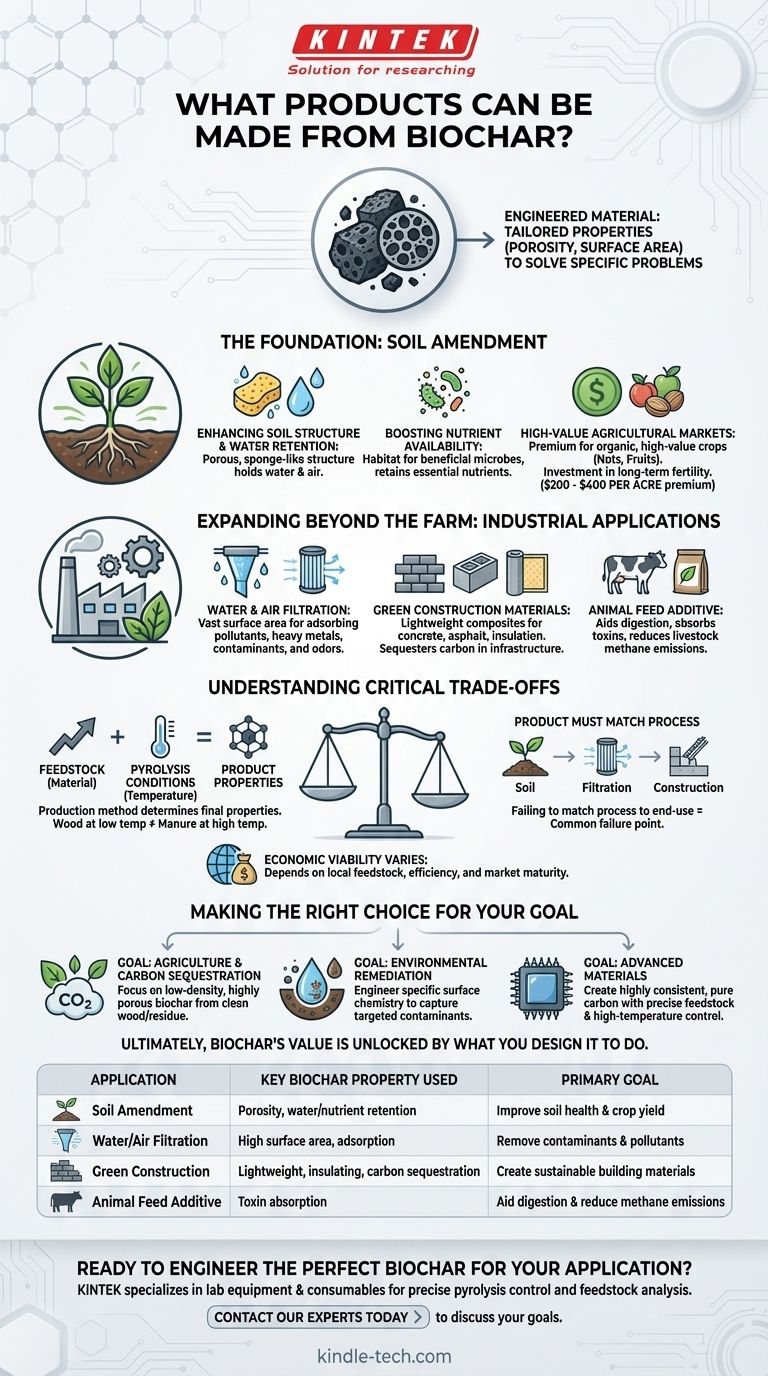

At its core, biochar is most widely known as a powerful soil amendment for agriculture. Its true potential, however, is as a versatile platform material whose unique physical properties are enabling a growing list of products across various industries, from filtration to construction.

While agriculture remains its primary market, thinking of biochar as a single product is a mistake. It is an engineered material whose value is unlocked by tailoring its specific properties—like porosity and surface area—to solve specific industrial or environmental problems.

The Foundation: Biochar as a Soil Amendment

The most established and commercially recognized use for biochar is to improve soil health. This application leverages its fundamental physical characteristics created during the pyrolysis process.

Enhancing Soil Structure and Water Retention

Biochar's incredibly porous, sponge-like structure is the key to its agricultural benefits. It creates microscopic pockets in the soil that hold water and air, improving drainage in dense soils and water retention in sandy soils.

Boosting Nutrient Availability

This same porous structure acts as a habitat for beneficial soil microbes. It also helps to retain essential nutrients, preventing them from being washed away by rain or irrigation and keeping them available for plant roots.

High-Value Agricultural Markets

The willingness of organic farmers and producers of high-value crops like nuts and fruits to pay a premium—sometimes $200 to $400 per acre—demonstrates this market's viability. These sectors see biochar as an investment in long-term soil fertility and crop resilience.

Expanding Beyond the Farm: Industrial Applications

The same properties that make biochar valuable in soil can be adapted for a range of industrial and environmental products. This is where the market is rapidly evolving.

Water and Air Filtration

Biochar's vast surface area and porous nature make it an excellent filtration medium. It can be used to adsorb and remove pollutants, heavy metals, and other contaminants from water or odors from the air.

"Green" Construction Materials

When incorporated into building materials, biochar creates lighter-weight composites. It is being used in concrete, asphalt, and insulation to reduce material weight, improve insulating properties, and, critically, sequester carbon directly within our infrastructure.

Animal Feed Additive

In specific forms, biochar is used as an additive to animal feed. It is believed to aid digestion, absorb toxins within an animal's gut, and reduce the methane emissions associated with livestock.

Understanding the Critical Trade-offs

Not all biochar is created equal. The potential to create different products is entirely dependent on how the biochar is made and from what materials.

Production Method is Everything

The properties of the final biochar product are determined by two things: the feedstock (the organic material being heated) and the pyrolysis conditions (especially temperature). A low-temperature biochar made from wood has very different properties than a high-temperature biochar made from manure.

Product Must Match the Process

Biochar intended for soil needs different characteristics than biochar intended for water filtration or use in concrete. Failing to match the production process to the end-use application is the most common reason for product failure and a poor return on investment.

Economic Viability is Not Guaranteed

While the applications are promising, the economic case for each depends on local feedstock costs, production efficiency, and the maturity of the target market. The agricultural market is established, but many industrial applications are still emerging.

Making the Right Choice for Your Goal

The "best" biochar product is entirely dependent on your primary objective. You must start with the problem you intend to solve.

- If your primary focus is agriculture and carbon sequestration: Focus on producing a low-density, highly porous biochar from clean wood or crop residue to maximize its value as a soil amendment.

- If your primary focus is environmental remediation: You will need to engineer biochar with a specific surface chemistry designed to capture the particular contaminants you are targeting in water or soil.

- If your primary focus is advanced materials: Your goal will be creating a highly consistent and pure carbon product, which requires precise control over feedstock and high-temperature production for applications in construction or electronics.

Ultimately, biochar's value is unlocked not by what it is, but by what you design it to do.

Summary Table:

| Application | Key Biochar Property Used | Primary Goal |

|---|---|---|

| Soil Amendment | Porosity, water/nutrient retention | Improve soil health & crop yield |

| Water/Air Filtration | High surface area, adsorption | Remove contaminants & pollutants |

| Green Construction | Lightweight, insulating, carbon sequestration | Create sustainable building materials |

| Animal Feed Additive | Toxin absorption | Aid digestion & reduce methane emissions |

Ready to Engineer the Perfect Biochar for Your Application?

The right production process is critical to your biochar's success. KINTEK specializes in the lab equipment and consumables needed to precisely control pyrolysis conditions and analyze feedstock, ensuring your biochar is tailored for maximum performance in agriculture, filtration, construction, or other advanced materials.

Contact our experts today to discuss how we can support your biochar production and research goals.

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How much temperature can graphite withstand? Unlock its true potential up to 3000°C

- Can graphite withstand high-temperature? Maximizing Performance in Controlled Atmospheres

- What is the temperature resistance of graphite? Unlocking Its High-Temp Potential in Your Lab

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- What is the graphite furnace used for? Achieve Extreme Heat Up to 3000°C in a Controlled Environment