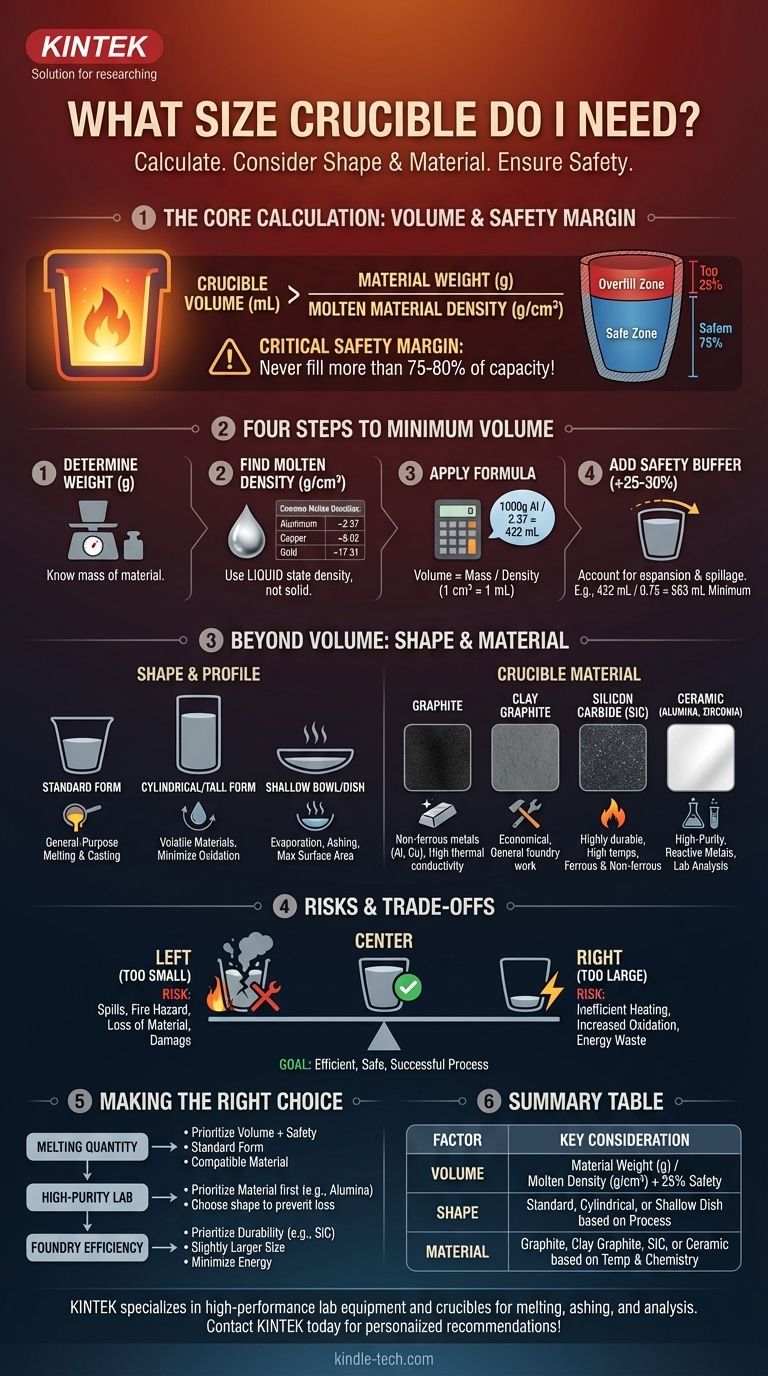

Choosing the right crucible size is a straightforward calculation based on the weight and density of the material you intend to heat. The fundamental formula is Crucible Volume (mL) > Material Weight (g) / Molten Material Density (g/cm³). However, you must also incorporate a critical safety margin, ensuring the crucible is never filled more than 75-80% of its total capacity to prevent dangerous spills.

Selecting a crucible requires you to look beyond simple volume. The correct choice balances three factors: the calculated volume of your material, the shape required by your process, and the crucible material's compatibility with your heating method and substance.

Calculating Your Minimum Crucible Volume

The first step is always to determine the minimum internal volume required to safely contain your material in its molten state. This is a four-step process.

Step 1: Determine the Weight of Your Material

First, know the mass of the material you plan to heat. For calculations, this should be in grams (g).

Step 2: Find the Density of Your Molten Material

You must use the density of the material in its liquid state, as most substances expand when heated. Using the solid-state density will result in a crucible that is too small.

A quick reference for common metals (approximate molten densities):

- Aluminum: 2.37 g/cm³

- Copper: 8.02 g/cm³

- Gold: 17.31 g/cm³

- Iron: 7.0 g/cm³

- Silver: 9.31 g/cm³

Step 3: Apply the Core Formula

The formula to find the required volume is Volume = Mass / Density. Since 1 cm³ is equal to 1 milliliter (mL), the result of your calculation will be the minimum volume in mL.

For example, to melt 1000g of aluminum:

1000g / 2.37 g/cm³ = 422 cm³, which means you need a minimum volume of 422 mL.

Step 4: Add a Critical Safety Margin

Never use a crucible that just barely holds your calculated volume. Always add a safety buffer of at least 25% to account for thermal expansion, bubbling, and to prevent spillage when handling with tongs.

A good rule of thumb is to never fill a crucible beyond 75-80% of its total rated capacity.

Continuing the example:

422 mL / 0.75 = 563 mL. You should look for a crucible with a rated capacity of at least 563 mL.

Why Size Isn't the Only Factor

The dimensions and material of the crucible are just as important as its volume. Different applications demand different solutions, and choosing incorrectly can lead to failed processes or damaged equipment.

Crucible Shape and Profile

The geometry of a crucible directly impacts its performance for a specific task.

- Standard Form: These are beaker-shaped and are excellent general-purpose crucibles for melting and casting.

- Cylindrical/Tall Form: A taller, narrower profile reduces the surface area, minimizing oxidation and preventing splashes. These are ideal for processes involving volatile materials.

- Shallow Bowl/Dish: A wide, shallow form maximizes the surface area, which is ideal for applications like evaporation or ashing samples in a laboratory.

Crucible Material

The crucible must be able to withstand the target temperature and be chemically inert to the substance being heated.

- Graphite: Excellent for melting non-ferrous metals like aluminum, brass, and gold due to its high thermal conductivity and resistance to thermal shock.

- Clay Graphite: A durable and economical choice for general foundry work with non-ferrous metals.

- Silicon Carbide (SiC): A highly durable, long-lasting material that handles very high temperatures and rapid temperature changes. It is suitable for both ferrous and non-ferrous metals.

- Ceramic (Alumina, Zirconia): Used for high-purity applications, laboratory analysis (TGA), or when melting reactive metals that would be contaminated by a carbon-based crucible.

Understanding the Trade-offs and Risks

Choosing the wrong crucible size or type carries significant consequences. Understanding the trade-offs is key to a safe and efficient process.

The Risk of a Crucible That's Too Small

This is the most dangerous mistake. A crucible that is too small will overflow as the material melts and expands. This leads to loss of valuable material, catastrophic damage to your furnace, and a serious fire or burn hazard.

The Problem with a Crucible That's Too Large

Using a grossly oversized crucible is inefficient and can harm your results. It requires significantly more energy to heat the crucible and its contents. It also increases the surface area-to-volume ratio, which can lead to greater heat loss and potential oxidation of the melt.

Material Incompatibility

Heating a substance in a chemically reactive crucible can destroy both the crucible and your material. For example, using a graphite crucible to melt iron at high temperatures can cause carbon to dissolve into the iron, changing its properties. Always verify material compatibility.

Making the Right Choice for Your Goal

Select your crucible by matching its specifications to the demands of your work.

- If your primary focus is melting a specific quantity of metal: Prioritize the volume calculation with a 25-30% safety buffer and choose a standard-form crucible made of a compatible material (like graphite or SiC).

- If your primary focus is a high-purity lab analysis or ashing: Focus on crucible material first (e.g., high-purity Alumina or Zirconia) and select a shape that prevents sample loss.

- If your primary focus is foundry efficiency and durability: Select a crucible that is only slightly larger than needed for your standard charge to minimize energy waste and invest in a durable material like Silicon Carbide to reduce long-term costs.

By considering volume, shape, and material together, you can select a crucible that ensures safety, efficiency, and successful results for your specific application.

Summary Table:

| Factor | Key Consideration |

|---|---|

| Volume | Material Weight (g) / Molten Density (g/cm³) + 25% safety margin. |

| Shape | Standard, Cylindrical, or Shallow Dish based on process needs (e.g., melting, evaporation). |

| Material | Graphite, Clay Graphite, Silicon Carbide, or Ceramic based on temperature and chemical compatibility. |

Selecting the right crucible is critical for safety and process success.

KINTEK specializes in providing high-performance lab equipment, including a wide range of crucibles for melting, ashing, and analysis. Our experts can help you choose the perfect crucible—considering volume, shape, and material—to ensure efficient, safe, and reliable results for your laboratory or foundry.

Contact KINTEK today to discuss your specific needs and get a personalized recommendation!

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

People Also Ask

- What is the most durable crucible? Match the Right Crucible to Your Melting Application

- Why is a PTFE crucible preferred for plasma etching? Ensure Chemical Integrity and Targeted Action

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container

- How do you clean a melting crucible? Protect Your Crucible and Ensure Metal Purity

- Why crucible is used during heating? Essential Guide for High-Temperature Containment