There is no single temperature for a heat treatment furnace. The correct temperature is entirely dictated by the specific material being treated and the desired change in its physical properties. This temperature is a precise variable, often falling within a range from a few hundred to well over a thousand degrees Celsius, but it must be carefully selected for each unique application.

The core principle to understand is that a furnace's temperature is not a fixed setting but a critical tool. It is set just high enough to trigger a specific microstructural change within a material—such as softening, hardening, or bonding—without reaching the point of melting or causing unintended damage.

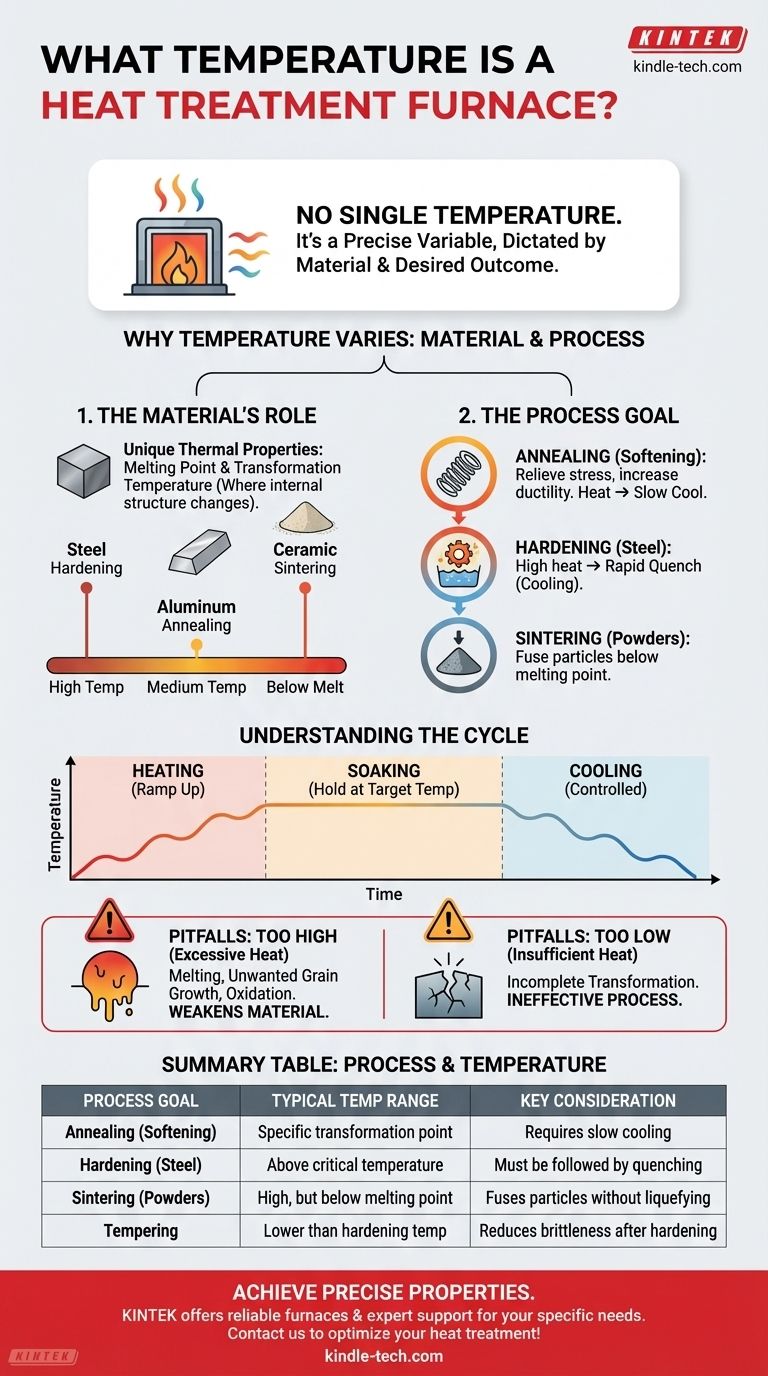

Why Temperature Varies: Material and Process

The temperature inside a heat treatment furnace is determined by two primary factors: the material you are working with and the outcome you need to achieve.

The Role of the Material

Every material has unique thermal properties, most critically its melting point and its transformation temperatures.

Transformation temperature is the point at which the internal crystal structure of a material begins to change. Heat treatment targets these specific temperatures to manipulate the material's properties.

For example, the temperatures required to harden steel are vastly different from those needed to anneal aluminum or sinter a ceramic powder.

The Influence of the Process

The goal of the heat treatment defines the temperature profile. A process like sintering, which fuses powdered material together, explicitly requires the furnace to remain below the material's melting point.

Other common processes have their own temperature requirements:

- Annealing (Softening): Heats material to a specific point to relieve internal stresses and increase ductility.

- Hardening: Heats certain steels to a high temperature before rapid cooling (quenching) to lock in a hard, brittle structure.

- Tempering: A lower-temperature process that follows hardening to reduce brittleness and add toughness.

Understanding Furnace Operation

A heat treatment cycle is more than just reaching a single temperature. It involves a controlled profile of heating, holding, and cooling.

The Heating and Soaking Phase

The furnace initially requires a significant amount of energy to reach the target temperature. This is the heating period.

Once the target is reached, the furnace enters a soaking or holding period. During this phase, the heat input is reduced to a level that simply maintains the constant, required temperature for a predetermined amount of time, allowing the entire part to undergo the desired transformation.

The Importance of Control

Precise temperature control is paramount. Even small deviations from the target temperature can lead to a failed process, resulting in a part that is too soft, too brittle, or has the wrong internal structure.

Common Pitfalls and Trade-offs

Selecting the wrong temperature is not a minor error; it fundamentally compromises the integrity of the material.

The Danger of Excessive Heat

Setting the temperature too high can be catastrophic. It can lead to unwanted grain growth (which weakens the material), surface oxidation, or, in the worst case, partial or complete melting of the component.

The Failure of Insufficient Heat

If the temperature is too low, the intended metallurgical transformation will not fully occur. The material will fail to achieve the desired hardness, softness, or stress relief, rendering the entire process ineffective.

Making the Right Choice for Your Goal

To determine the correct temperature, you must first define your objective.

- If your primary focus is to soften metal and relieve stress: You will be using an annealing process, which requires heating the material to a specific transformation point and then cooling it very slowly.

- If your primary focus is to harden a steel component: You will heat the material above its critical temperature before quenching it, a process that demands precise control to avoid cracking.

- If your primary focus is to form a solid part from powder: You will use a sintering process, carefully calculating a temperature high enough to bond particles but safely below the melting point.

Ultimately, the right temperature is the one that reliably and repeatedly produces the exact material properties your application demands.

Summary Table:

| Process Goal | Typical Temperature Range | Key Consideration |

|---|---|---|

| Annealing (Softening) | Specific material transformation point | Requires slow cooling |

| Hardening (Steel) | Above critical temperature | Must be followed by quenching |

| Sintering (Powders) | High, but below melting point | Fuses particles without liquefying |

| Tempering | Lower than hardening temperature | Reduces brittleness after hardening |

Achieve precise material properties with every cycle. The correct furnace temperature is critical to your success. KINTEK specializes in lab equipment and consumables, providing reliable heat treatment furnaces and expert support for your laboratory needs. Let our team help you select the right equipment and parameters for your specific materials and goals. Contact us today to optimize your heat treatment processes!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation