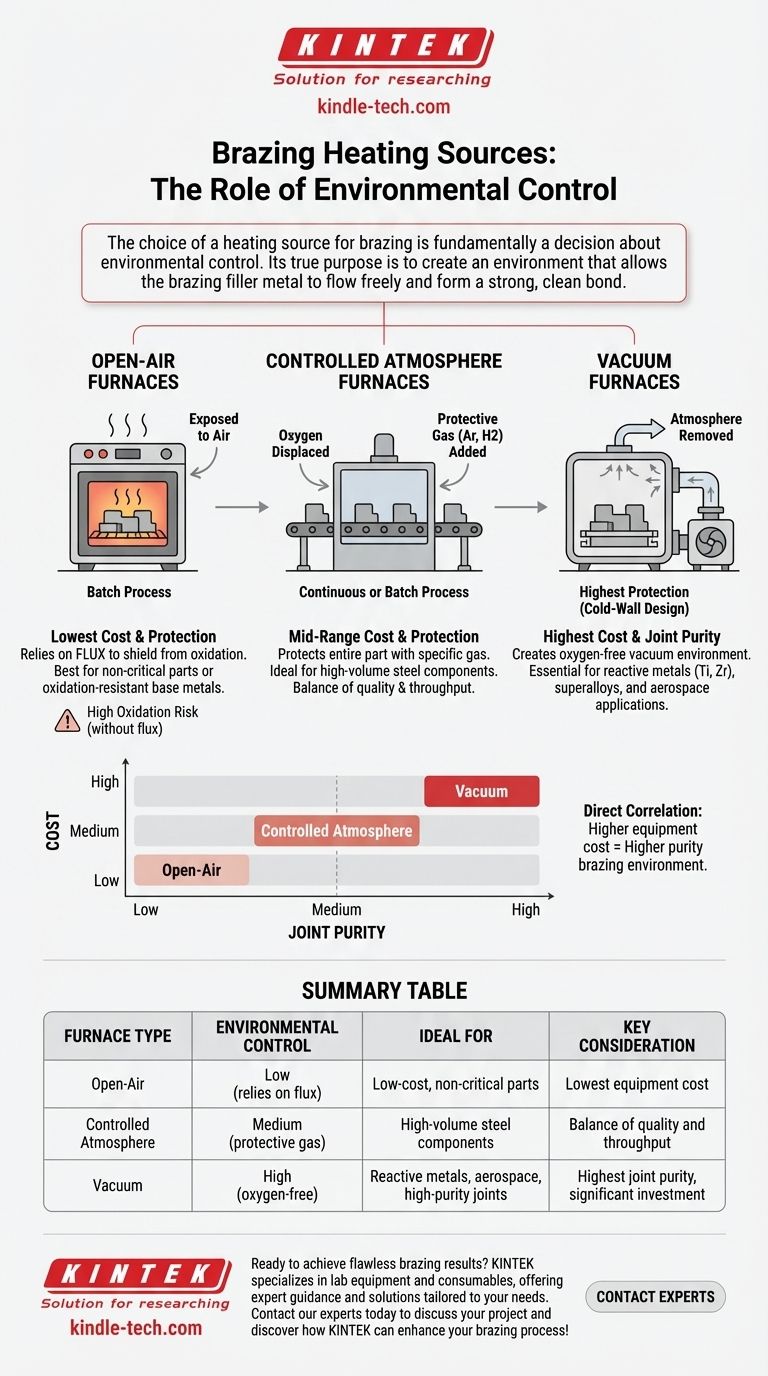

Brazing relies almost exclusively on specialized furnaces that provide both high heat and a controlled environment. The primary types are open-air furnaces, controlled (or inert) atmosphere furnaces, and vacuum furnaces, each designed to manage heat and prevent the oxidation that can ruin a brazed joint.

The choice of a heating source for brazing is fundamentally a decision about environmental control. While all methods provide the necessary temperature, their true purpose is to create an environment—whether by using a protective gas or a vacuum—that allows the brazing filler metal to flow freely and form a strong, clean bond.

The Critical Role of the Brazing Environment

The fundamental challenge in brazing is that the high temperatures required to melt the filler metal also cause the base metals to oxidize rapidly. This thin layer of oxide acts as a barrier, preventing the filler metal from "wetting" the surfaces and flowing into the joint, which results in a failed braze.

The Purpose of a Brazing Furnace

A brazing furnace's primary job is not just to heat the parts, but to protect them from oxygen and other contaminants during the heating and cooling cycle. This protection is what separates the different furnace technologies.

The Impact of Oxidation

If oxygen is present, it will bond with the base metal, creating a non-metallic surface that the liquid filler metal cannot bond with. This leads to weak joints, voids, and complete joint failure.

Common Brazing Furnace Technologies

The method you choose depends on the materials being joined, the required joint quality, and production volume.

Open-Air Furnaces

This is the simplest furnace type, essentially a high-temperature oven. It's a batch process, meaning parts are loaded, heated, and removed in groups.

Because the parts are exposed to air, this method is only suitable for base metals that are highly resistant to oxidation or when a chemical flux is applied to the joint. The flux melts and shields the joint area from oxygen.

Controlled Atmosphere Furnaces

These furnaces are designed to displace the oxygen-rich air with a specific gas. This atmosphere protects the entire part, not just the joint area.

They can be batch type, like a retort furnace where parts are sealed in a container filled with a protective gas, or continuous type, where parts move on a conveyor belt through a long chamber filled with gas. Common atmospheres include inert gases like argon or active gases like hydrogen, which chemically reduces oxides.

Vacuum Furnaces

Vacuum furnaces represent the highest level of environmental control. Instead of replacing the air with another gas, a powerful pump system removes the atmosphere entirely.

By creating a vacuum, there are virtually no molecules left to cause oxidation or contamination. These furnaces typically use a cold-wall design, where the furnace shell is water-cooled while internal heating elements, often made of molybdenum or carbon, bring the parts to temperature. This provides extremely clean, high-purity brazing, essential for reactive metals and critical applications.

Understanding the Trade-offs

Choosing a furnace involves balancing cost, production needs, and quality requirements.

Cost vs. Joint Purity

There is a direct correlation between the cost of the equipment and the purity of the brazing environment it creates.

Open-air furnaces are the least expensive but offer the lowest level of protection, relying entirely on flux. Controlled atmosphere furnaces are a mid-range option, while high-purity vacuum furnaces are the most significant capital investment.

Batch vs. Continuous Processing

Batch furnaces (like retort or most vacuum furnaces) offer flexibility. They are ideal for lower volume production, a wide variety of part sizes, or for processes requiring long, complex heating cycles.

Continuous furnaces are built for efficiency and high-volume production. They excel at brazing large quantities of similar parts with a consistent, repeatable process, significantly lowering the cost per part.

Material Compatibility and Application

The materials being joined often dictate the necessary environment. Standard steels can often be brazed in a controlled atmosphere. However, reactive metals like titanium or zirconium, or superalloys used in aerospace, require a vacuum to prevent the formation of brittle compounds.

Selecting the Right Furnace for Your Application

Your final choice depends entirely on your project's specific goals.

- If your primary focus is low-cost production of non-critical parts: An open-air furnace combined with an appropriate chemical flux is the most economical solution.

- If your primary focus is high-volume manufacturing of steel components: A continuous controlled atmosphere furnace provides an excellent balance of quality and throughput efficiency.

- If your primary focus is achieving the highest possible joint strength or brazing reactive metals: A vacuum furnace is the only choice to ensure an exceptionally clean, oxide-free environment.

Ultimately, selecting the right heating source is about matching the level of environmental control to the demands of your materials and the quality standards of your final product.

Summary Table:

| Furnace Type | Environmental Control | Ideal For | Key Consideration |

|---|---|---|---|

| Open-Air | Low (relies on flux) | Low-cost, non-critical parts | Lowest equipment cost |

| Controlled Atmosphere | Medium (protective gas) | High-volume steel components | Balance of quality and throughput |

| Vacuum | High (oxygen-free) | Reactive metals, aerospace, high-purity joints | Highest joint purity, significant investment |

Ready to achieve flawless brazing results? The right furnace is critical for joint strength and production efficiency. At KINTEK, we specialize in lab equipment and consumables, offering expert guidance and solutions tailored to your laboratory's brazing needs. Whether you're working with standard steels or reactive aerospace alloys, we can help you select the perfect heating source for your application. Contact our experts today to discuss your project and discover how KINTEK can enhance your brazing process!

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- Which material is suitable for hardening? The Critical Role of Carbon Content in Steel Selection

- How do you clean a vacuum furnace? A Step-by-Step Guide to Prevent Contamination and Ensure Process Integrity

- What is the hottest temperature in the industrial furnace? Find the Right Heat for Your Process

- How does a sintering furnace influence EDC powder metallurgy electrodes? Optimize Your Tool for Superior Coatings

- What are the byproducts of pyrolysis? A Guide to Biochar, Bio-Oil, and Syngas

- What is the process of vacuum arc remelting? Achieve Ultimate Purity for High-Performance Alloys

- Why is a molybdenum heating furnace utilized for TiB2-Al2O3 composites? Control Preheating for Precision Synthesis

- Why is a vacuum drying oven utilized for AlCrFeNiTix powders? Prevent Oxidation & Preserve High-Entropy Alloy Purity