In essence, a hydraulic press is a machine that uses a liquid to multiply force. It operates on a fundamental principle of fluid mechanics to take a small initial force and convert it into an immense compressive force, making it indispensable for tasks like crushing, molding, and forging materials.

A hydraulic press is not defined by its speed but by its power. It is a force multiplier that leverages an incompressible fluid to translate a small force applied to a small area into a massive force exerted over a larger area.

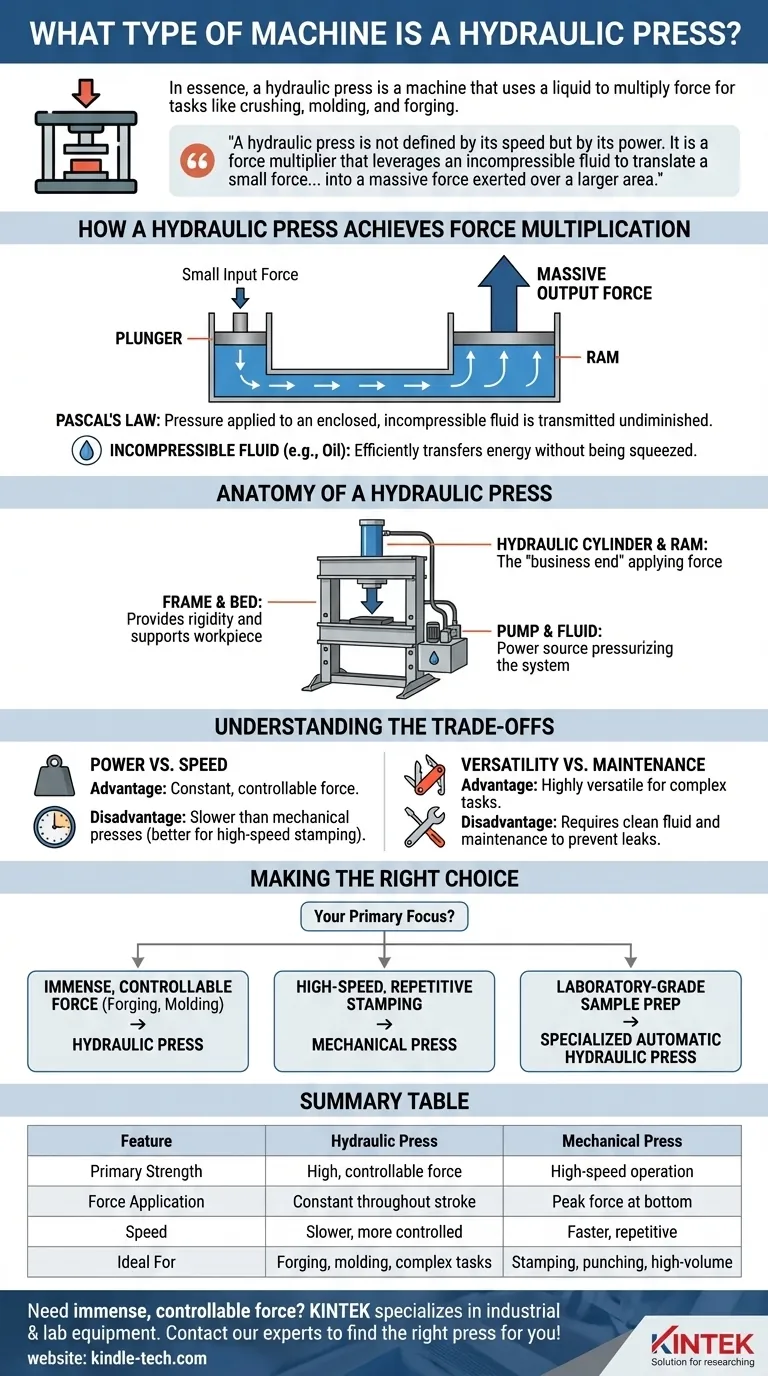

How a Hydraulic Press Achieves Force Multiplication

The "magic" of a hydraulic press lies in a core physics principle that governs how pressure behaves in a contained fluid. This allows it to generate forces far beyond what mechanical levers or screws could easily achieve.

The Core Principle: Pascal's Law

A hydraulic press is a direct application of Pascal's Law, which states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

The system uses two interconnected cylinders of different sizes: a small one called the Plunger and a larger one called the Ram.

When a small force is applied to the Plunger, it creates pressure in the hydraulic fluid. This same pressure is then exerted on the much larger surface area of the Ram, resulting in a significantly larger output force.

The Role of Incompressible Fluid

The system relies on a hydraulic fluid, typically a specialized oil, because liquids are effectively incompressible.

This property ensures that when pressure is applied, the fluid doesn't lose energy by being squeezed. Instead, it efficiently transfers that energy from the small piston to the large one.

Anatomy of a Hydraulic Press: The Key Components

While designs vary, all hydraulic presses are built around a few essential components that work together to generate and apply force.

The Frame and Bed

The frame is the main structure that provides rigidity and strength, holding all other components in place.

The bed (also called a table or bolster) is the flat, stable surface that supports the material or workpiece being pressed.

The Hydraulic Cylinder and Ram

The hydraulic cylinder is a sealed tube containing a piston. The Ram is the component that moves out of the cylinder to apply the compressive force.

It is the large-diameter piston in the system and represents the "business end" of the press.

The Pump and Hydraulic Fluid

The pump is the power source. It is responsible for pressurizing the hydraulic fluid and forcing it into the cylinder to move the ram.

The entire system of cylinders and hoses is filled with hydraulic fluid, which acts as the medium for transferring the force generated by the pump.

Understanding the Trade-offs

While incredibly powerful, hydraulic presses are not the solution for every application. Their design creates specific advantages and disadvantages compared to other types of presses, such as mechanical ones.

Power vs. Speed

The primary advantage of a hydraulic press is its ability to deliver a constant, controllable force throughout the entire stroke. However, this often comes at the cost of speed.

Hydraulic systems are generally slower than mechanical presses, which are better suited for high-speed, repetitive stamping operations.

Versatility vs. Maintenance

The control over pressure and speed makes hydraulic presses highly versatile for complex forging and molding tasks.

However, the hydraulic system introduces complexity. It requires clean fluid and a well-maintained system to prevent leaks, which can be a common point of failure if neglected.

Making the Right Choice for Your Application

Understanding the fundamental purpose of a hydraulic press clarifies when it is the correct tool for the job. Your decision should be based on the specific requirements of the task at hand.

- If your primary focus is immense, controllable force: A hydraulic press is the ideal choice for forging, molding, or compressing tough materials with high precision.

- If your primary focus is high-speed, repetitive stamping: A mechanical press, which completes a cycle with each turn of a flywheel, is likely a more efficient solution.

- If your primary focus is laboratory-grade sample preparation: A specialized automatic hydraulic press is designed to deliver consistent, programmable pressure for creating pellets.

Ultimately, a hydraulic press is a foundational engineering tool that translates the simple properties of fluid into powerful, controlled force.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Primary Strength | High, controllable force | High-speed operation |

| Force Application | Constant throughout the stroke | Peak force at bottom of stroke |

| Speed | Slower, more controlled | Faster, repetitive |

| Ideal For | Forging, molding, complex tasks | Stamping, punching, high-volume |

Need immense, controllable force for your project? KINTEK specializes in industrial and laboratory equipment, including hydraulic presses designed for demanding applications like material testing, sample preparation, and R&D. Our expertise ensures you get the right press for your specific needs, from heavy-duty forging to precise lab work. Contact our experts today to discuss how a KINTEK hydraulic press can enhance your productivity and precision!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the causes of heat generation in hydraulic systems? Uncover the Key Sources of Energy Loss

- What are five things you should consider when using a hydraulic press? Ensure Safe and Efficient Operation

- How is a laboratory hydraulic press utilized in the fabrication of molybdenum disulfide cathode cylinders? Expert Guide

- How do you prepare samples for XRF? A Guide to Pressed Pellets, Fused Beads, and Solid Polishing

- What are three ways to reduce production time in compression molding? Optimize Design, Preheat, and Automate

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press serve in copper-nickel alloy forming? Achieve High-Density Green Bodies

- Is a hydraulic press safe? How to Mitigate Crushing, Injection, and Failure Risks