For powder metallurgy (PM), the choice of sintering furnace is dictated almost entirely by production volume and temperature requirements. For high-volume manufacturing, continuous furnaces are the standard, while batch furnaces are reserved for smaller or more specialized production runs. Within continuous systems, belt furnaces are used for lower temperatures, and pusher-plate furnaces are required for higher-temperature applications.

The decision is not about finding the "best" furnace, but about matching the furnace's operational model—continuous for scale, batch for flexibility—to the specific temperature, atmosphere, and throughput demands of your material and production goals.

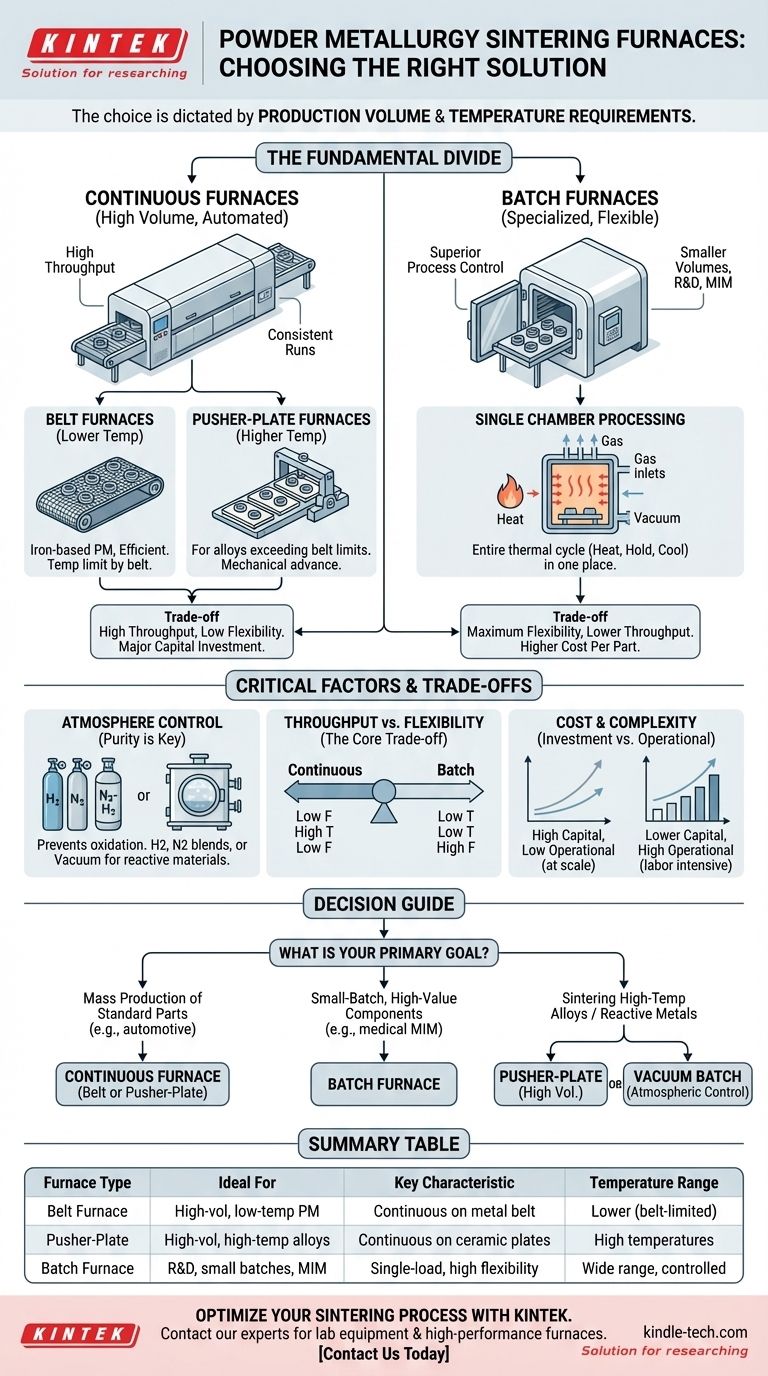

The Fundamental Divide: Continuous vs. Batch Furnaces

The first and most important distinction in PM sintering furnaces is their mode of operation. This choice directly impacts production capacity, cost per part, and operational flexibility.

Continuous Furnaces: The Workhorse of High-Volume PM

A continuous furnace is designed for high-throughput, automated production, making it ideal for industries like automotive manufacturing.

Parts are constantly fed into one end of a long oven, move through various pre-heating, sintering, and cooling zones, and emerge finished at the other end. This setup maximizes efficiency for large, consistent production runs of the same part.

Batch Furnaces: Precision for Specialized Applications

Batch furnaces process parts one load, or "batch," at a time. The entire thermal cycle—heating, holding, and cooling—occurs within a single chamber.

This method offers superior process control and flexibility, making it suitable for smaller production volumes, research and development, or complex parts like those made via Metal Injection Molding (MIM).

Choosing the Right Continuous Furnace

For high-volume needs, the primary deciding factor between continuous furnace types is the sintering temperature required by the powder material.

Belt Furnaces: The Standard for Lower Temperatures

In a belt furnace, parts travel through the heat zones on a high-temperature metal mesh belt.

This is a highly efficient and common method for sintering many iron-based PM components. However, the belt material itself has a temperature limit, making this design unsuitable for higher-heat applications.

Pusher-Plate Furnaces: For High-Temperature Demands

When sintering temperatures exceed what a mesh belt can withstand, a pusher-plate furnace is necessary.

Instead of a belt, parts are loaded onto ceramic or metallic plates. A mechanical "pusher" mechanism then incrementally advances the entire line of plates through the furnace, allowing for much higher operating temperatures.

Understanding the Trade-offs

Selecting a furnace involves balancing throughput with process control and material compatibility. The furnace is more than just a heater; it's a controlled environment.

Throughput vs. Flexibility

The core trade-off is simple: continuous furnaces offer high throughput but are inflexible. They are optimized for one process and running them for short, varied jobs is highly inefficient.

Batch furnaces offer maximum flexibility to change temperature profiles and atmospheres for each load, but at the cost of significantly lower throughput.

The Critical Role of Atmosphere Control

Sintering must occur in a controlled atmosphere to prevent oxidation and facilitate the bonding of metal particles. Furnaces are designed to operate with specific atmospheres, such as hydrogen, nitrogen-hydrogen blends, or a vacuum.

The choice of atmosphere depends on the metal being processed. A furnace must be able to maintain the purity and integrity of this atmosphere, with vacuum furnaces representing a highly specialized category for reactive or high-performance materials.

Cost and Complexity

Continuous furnaces are a major capital investment and require significant floor space. Their operational efficiency only pays off at high, sustained production volumes.

Batch furnaces are typically less expensive to purchase and install but have a much higher cost per part due to lower throughput and labor-intensive loading and unloading.

Making the Right Choice for Your Goal

Your application's specific requirements for volume, material, and complexity will point directly to the correct furnace technology.

- If your primary focus is mass production of standard parts (e.g., automotive gears): A continuous furnace—belt or pusher, depending on the material's temperature needs—is the only viable option.

- If your primary focus is small-batch, high-value components (e.g., medical MIM parts): A batch furnace provides the essential process control and flexibility for different materials and complex cycles.

- If your primary focus is sintering high-temperature alloys or reactive metals: You will require a pusher-plate continuous furnace for high volume or a specialized vacuum batch furnace for ultimate atmospheric control.

Ultimately, selecting the right furnace is a strategic decision that aligns the technology with your specific manufacturing volume, material, and quality requirements.

Summary Table:

| Furnace Type | Ideal For | Key Characteristic | Temperature Range |

|---|---|---|---|

| Belt Furnace | High-volume, low-temp PM parts | Continuous operation on a metal belt | Lower temperatures (belt-limited) |

| Pusher-Plate Furnace | High-volume, high-temp alloys | Continuous operation on ceramic plates | High temperatures |

| Batch Furnace | R&D, small batches, MIM parts | Single-load processing with high flexibility | Wide range, highly controlled |

Optimize your powder metallurgy sintering process with the right equipment. KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-performance sintering furnaces. Whether you require the high throughput of a continuous furnace or the precise control of a batch system, our experts can help you select the perfect solution for your material and production goals. Contact us today to discuss your specific application and enhance your manufacturing efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Why must green bodies produced via binder jetting undergo treatment in a vacuum sintering furnace?