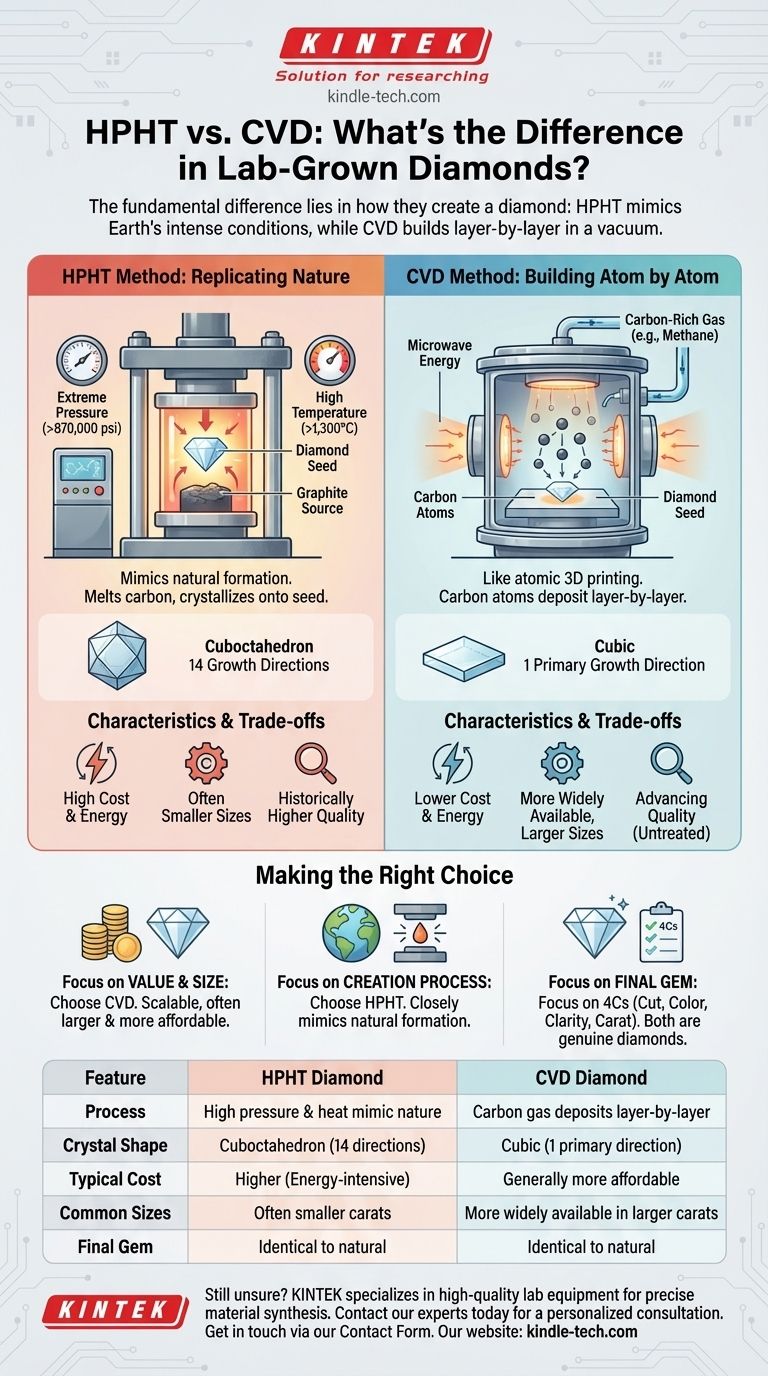

The fundamental difference between HPHT and CVD lies in how they create a diamond. The High-Pressure, High-Temperature (HPHT) method replicates the intense conditions deep within the Earth, using immense pressure and heat to crystallize carbon. In contrast, the Chemical Vapor Deposition (CVD) method builds a diamond layer by layer in a vacuum chamber using a carbon-rich gas, operating at much lower pressures and temperatures.

Your choice between an HPHT and a CVD diamond is not about finding a "better" or "more real" option, as both are chemically and physically genuine diamonds. The decision hinges on understanding the trade-offs between their production methods, which directly impact final cost, availability, and certain subtle characteristics.

How Each Diamond Is Made

To understand the differences, we must first look at the distinct creation process for each type of lab-grown diamond. Both start with a tiny diamond "seed" to act as a template.

The HPHT Method: Replicating Nature

The HPHT process is engineered to mimic the natural diamond formation process. A diamond seed is placed in a cell with a carbon source, typically graphite.

This cell is then subjected to extreme conditions inside a large press: pressures over 870,000 pounds per square inch and temperatures exceeding 1,300°C (2,372°F). This immense pressure and heat melts the carbon, which then crystallizes onto the diamond seed, growing a larger, rough diamond.

The CVD Method: Building Atom by Atom

The CVD process is more akin to atomic-level 3D printing. A diamond seed is placed inside a vacuum chamber.

The chamber is filled with a carbon-rich gas, like methane, and heated. Microwave energy is introduced, breaking the gas molecules apart. These free carbon atoms then "rain" down and deposit onto the diamond seed, building the diamond one atomic layer at a time.

The Impact on Physical Characteristics

The two distinct growth environments create diamonds with different internal growth patterns and market characteristics, even though they appear identical to the naked eye.

Crystal Growth and Shape

The most fundamental difference is in their growth morphology. HPHT diamonds grow in a cuboctahedron shape, forming outward in 14 different directions.

CVD diamonds grow in a cubic shape, with the carbon depositing in just one primary direction, resulting in a flatter, tabular crystal. For context, natural diamonds typically grow in an octahedron shape with 8 growth directions.

Quality and Clarity

Historically, the HPHT process allowed for more control over the growth environment, often resulting in higher-quality diamonds that required less post-growth treatment to enhance their color or clarity.

However, CVD technology is advancing rapidly. While some CVD diamonds may still undergo treatments, the quality of untreated stones has improved significantly, making this distinction less pronounced than it once was.

Visible Differences

To a consumer, there are no visible differences. Both HPHT and CVD diamonds are real diamonds with the same brilliance, fire, and durability. Only a gemologist with specialized equipment can distinguish between them by identifying their unique microscopic growth patterns and trace elements.

Understanding the Trade-offs

The choice between HPHT and CVD often comes down to practical considerations rooted in their production methods.

Cost and Energy Consumption

The HPHT method requires massive, expensive machinery and consumes a significant amount of energy to generate the necessary pressure and heat.

The CVD method is less energy-intensive and does not have the same high equipment and maintenance costs. This efficiency often translates into a more competitively priced final product for the consumer.

Size and Availability

Because the CVD process is more scalable and cost-effective, CVD diamonds are more widely available, particularly in larger carat sizes. The high costs and technical limitations of HPHT presses mean they are often used to produce smaller diamonds.

Making the Right Choice: HPHT vs. CVD

Your final decision should be based on your personal priorities, not a perceived superiority of one method over the other.

- If your primary focus is value and size: CVD is likely your best option, as the scalable and less expensive process often yields larger, more affordable diamonds.

- If your primary focus is the creation process: HPHT may be more appealing, as its use of high pressure and temperature more closely mimics how diamonds form in nature.

- If your primary focus is the final gem: Concentrate on the individual diamond's 4Cs (Cut, Color, Clarity, and Carat) and its certification report, as these factors determine its beauty and value far more than its growth method.

Ultimately, both methods produce a genuine diamond, and your final decision should be guided by the specific stone's quality, beauty, and your personal budget.

Summary Table:

| Feature | HPHT Diamond | CVD Diamond |

|---|---|---|

| Process | High pressure & heat mimic nature | Carbon gas deposits layer-by-layer |

| Crystal Shape | Cuboctahedron (14 directions) | Cubic (1 primary direction) |

| Typical Cost | Higher due to energy-intensive process | Generally more affordable |

| Common Sizes | Often smaller carats | More widely available in larger carats |

| Final Gem | Chemically and physically identical to natural diamond | Chemically and physically identical to natural diamond |

Still unsure which lab-grown diamond method is right for your application?

Whether you're in research, manufacturing, or jewelry design, choosing the right diamond is critical. KINTEK specializes in providing high-quality lab equipment and consumables for precise material synthesis and analysis.

We can help you navigate the complexities of diamond creation to find the perfect solution for your laboratory's specific needs.

Contact our experts today for a personalized consultation and discover how KINTEK's solutions can enhance your project's success.

Get in touch via our Contact Form

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition