The hydraulic press was invented in 1795 by the English inventor Joseph Bramah. He developed the first practical application of a scientific principle to create a machine capable of generating immense force. Bramah's invention was a pivotal moment in the Industrial Revolution, enabling new manufacturing capabilities that were previously impossible.

The invention of the hydraulic press is a classic example of applying a known scientific law—in this case, Pascal's Law—to solve a critical engineering problem. Its genius lies not in a new discovery, but in the practical design that unlocked the principle of force multiplication.

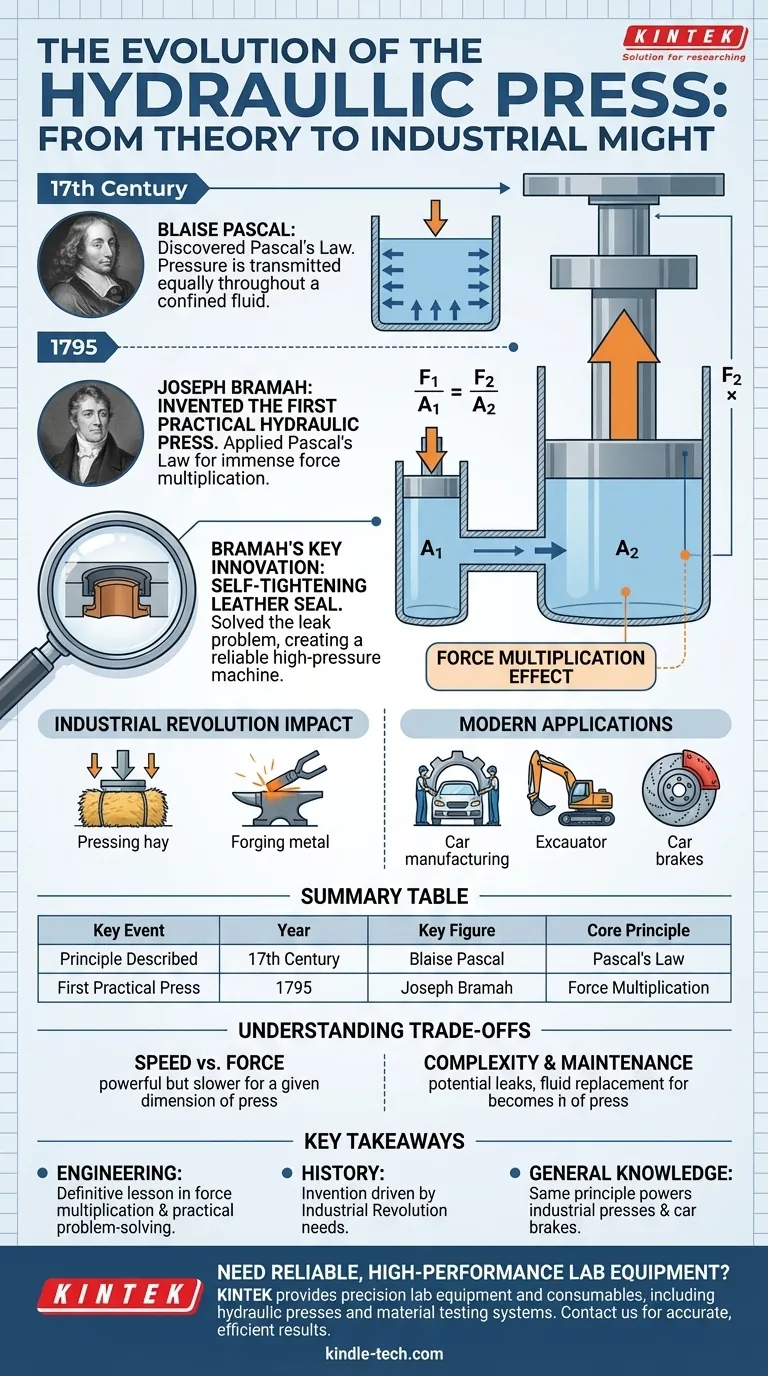

The Scientific Foundation: Pascal's Law

The hydraulic press works because of a fundamental principle of fluid mechanics first described by Blaise Pascal in the 17th century.

What is Pascal's Law?

Pascal's Law states that a pressure change at any point in a confined, incompressible fluid is transmitted equally throughout the fluid. In simpler terms, if you push on a liquid in a sealed container, the pressure increases everywhere inside that container at the same time.

The Force Multiplication Effect

This is where the magic happens. A hydraulic system typically uses two pistons of different sizes connected by a pipe filled with fluid.

When a small force is applied to the small piston, it creates pressure in the fluid. According to Pascal's Law, this exact same pressure pushes up on the large piston.

Because the large piston has a much bigger surface area, that same pressure results in a much larger output force. The force is multiplied by the ratio of the areas of the two pistons, allowing a small input effort to lift or compress an enormous load.

From Theory to Application: Joseph Bramah's Invention

While Pascal described the principle, it was Joseph Bramah who turned it into a working machine over a century later.

The Problem Bramah Was Solving

During the Industrial Revolution, there was a growing need to shape, press, and form materials with forces that were beyond the capability of mechanical levers or screws. Industries needed a way to apply controlled, massive pressure.

Bramah's Key Innovation

Bramah's true genius was not in rediscovering the principle, but in solving the practical engineering challenge: preventing leaks. Creating a seal that could withstand the extremely high pressures required for force multiplication was the critical barrier.

He developed and patented a self-tightening leather seal, which used the fluid pressure itself to press the seal more tightly against the cylinder wall. The higher the pressure, the tighter the seal became, a brilliantly simple and effective solution.

The Impact of the Bramah Press

The first Bramah Press was a revolutionary tool. It was used for everything from pressing hay and cotton into compact bales to forging metal parts and uprooting trees. It provided a level of force that fundamentally changed what was possible in manufacturing and engineering.

Understanding the Trade-offs

Like any technology, hydraulic systems have inherent trade-offs that are important to understand.

Speed vs. Force

A key trade-off in hydraulic systems is speed for force. To achieve massive force multiplication, the large piston must travel a much shorter distance than the small input piston. This often makes hydraulic presses powerful but significantly slower than their mechanical counterparts.

System Complexity and Maintenance

Hydraulic systems require a pump, fluid reservoir, high-pressure hoses, valves, and cylinders. This complexity introduces potential points of failure, with fluid leaks being a primary maintenance concern. The hydraulic fluid itself must also be kept clean and may need to be replaced periodically.

The Modern Impact of Hydraulic Power

Bramah's application of Pascal's Law laid the groundwork for all modern hydraulic systems, which are ubiquitous today.

Industrial Manufacturing

The hydraulic press remains a cornerstone of heavy industry. It is used for stamping car body panels, forging high-strength components for aerospace, and molding plastic and composite materials.

Construction and Heavy Equipment

The principle of hydraulic force multiplication powers nearly all heavy construction equipment. The powerful and precise movements of excavators, bulldozers, and cranes are all achieved with hydraulic systems.

Everyday Applications

You interact with hydraulic principles more often than you think. The braking system in your car is a hydraulic system that multiplies the force from your foot on the pedal to clamp the brake pads onto the rotors with immense pressure.

Key Takeaways for Your Perspective

- If your focus is on engineering: The hydraulic press is the definitive lesson in force multiplication, and Bramah's seal is a reminder that solving the "simple" practical problems is often the key to unlocking a powerful theory.

- If your focus is on history: The invention was a direct response to the needs of the Industrial Revolution, demonstrating how scientific application drives technological progress.

- If your focus is on general knowledge: Recognize that the same principle that allows a massive industrial press to shape steel also allows your car's brakes to work safely and effectively.

Applying a fundamental law of physics enabled a single person's effort to be magnified into a force capable of shaping the modern world.

Summary Table:

| Key Event | Year | Key Figure | Core Principle |

|---|---|---|---|

| Principle Described | 17th Century | Blaise Pascal | Pascal's Law |

| First Practical Hydraulic Press Invented | 1795 | Joseph Bramah | Force Multiplication |

Need reliable, high-performance lab equipment to apply powerful principles in your work? KINTEK specializes in precision lab equipment and consumables, serving diverse laboratory needs. From hydraulic presses to advanced material testing systems, our solutions help you achieve accurate, efficient results. Contact us today to explore how our expertise can support your laboratory's success!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy