Horizontal furnaces are specifically designed for installation in spaces with low vertical clearance. They are most commonly installed in areas like attics, crawl spaces, and above suspended ceilings, but are also used in basements, garages, or utility rooms where a horizontal orientation is a better fit for the available space and ductwork layout.

The primary reason to choose a horizontal furnace is not preference, but necessity. It is the definitive solution for providing forced-air heating in structures where there is insufficient vertical space for a traditional upflow or downflow unit.

Why a Horizontal Furnace is a Space-Saving Solution

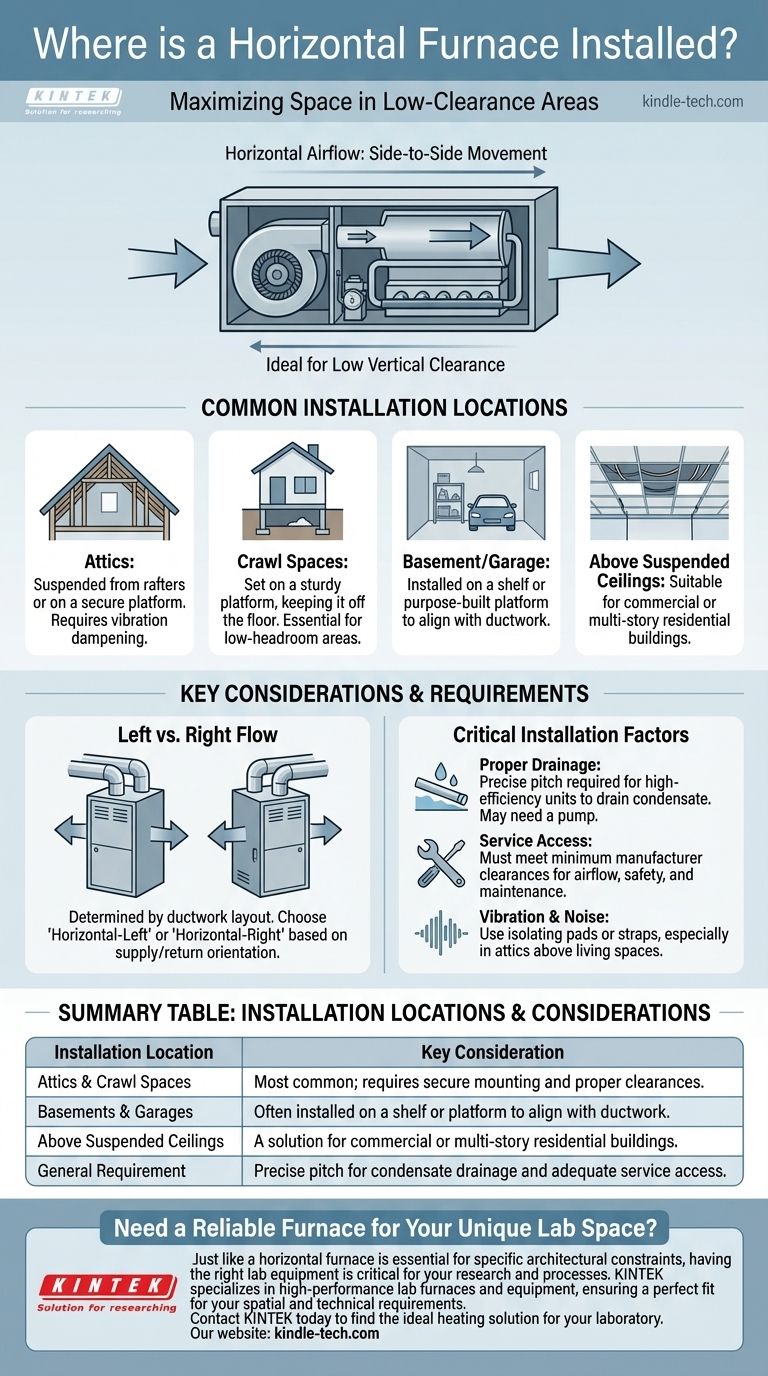

A horizontal furnace contains the same core components as a standard vertical furnace—a burner, heat exchanger, and blower fan. The key difference is that these components are arranged to lie flat, allowing the unit to move air from side to side rather than top to bottom.

Common Installation Locations

The design of a horizontal furnace makes it ideal for long, low areas. The most frequent locations include attics and crawl spaces, where the furnace can be suspended from the rafters or set on a secure platform.

Other common spots are basements and garages, typically on a shelf or purpose-built platform to keep the unit off the floor and align it with existing ductwork.

Understanding "Left" vs. "Right" Flow

When planning an installation, you will encounter the terms "horizontal-right" or "horizontal-left." This simply describes the direction of airflow as you face the front of the furnace.

A "horizontal-right" unit pulls return air from the left and sends heated supply air out to the right. A "horizontal-left" unit does the opposite. The correct choice is determined entirely by your home's ductwork configuration.

Understanding the Trade-offs and Installation Requirements

While they solve a critical space problem, horizontal installations have specific requirements that must be met to ensure safety and longevity. Ignoring these can lead to premature system failure and costly repairs.

Proper Drainage is Non-Negotiable

High-efficiency condensing furnaces produce water (condensate) as a byproduct of combustion. In a horizontal installation, the unit must be precisely pitched according to the manufacturer's specifications to ensure this water drains out of the unit correctly.

Improper drainage can cause water to pool inside the furnace, leading to a corroded heat exchanger, damaged electrical components, and eventual system shutdown. A condensate pump is often required to move the water to a suitable drain.

Service Access and Clearances

You cannot simply slide the furnace into the tightest possible space. Manufacturers specify minimum clearances on all sides of the unit.

These clearances are required for proper airflow, heat dissipation, and, most importantly, to provide service access for a technician to perform routine maintenance and repairs.

Vibration and Noise Considerations

A furnace installed in an attic directly above a living space can transmit vibration and noise. Professional installers use vibration-isolating pads or hanging straps to dampen the operational noise of the blower motor and fans, preventing it from becoming a nuisance in the home.

Making the Right Choice for Your Goal

The decision to use a horizontal furnace is almost always dictated by the physical constraints of the building.

- If your primary focus is fitting a system into a space with low ceilings (like an attic or crawl space): A horizontal furnace is the correct and often only choice for a forced-air system.

- If your primary focus is simplicity of installation in a tall, open area (like a full basement or utility closet): A traditional vertical upflow or downflow furnace is generally easier to install and service.

- If your primary focus is replacing an existing unit: The orientation of the old furnace and the layout of your current ductwork will be the most significant factors in your decision.

Ultimately, the correct furnace orientation is dictated by the architecture of your space, ensuring efficient and serviceable heating for years to come.

Summary Table:

| Installation Location | Key Consideration |

|---|---|

| Attics & Crawl Spaces | Most common; requires secure mounting and proper clearances. |

| Basements & Garages | Often installed on a shelf or platform to align with ductwork. |

| Above Suspended Ceilings | A solution for commercial or multi-story residential buildings. |

| General Requirement | Precise pitch for condensate drainage and adequate service access. |

Need a Reliable Furnace for Your Unique Lab Space?

Just like a horizontal furnace is essential for specific architectural constraints, having the right lab equipment is critical for your research and processes. KINTEK specializes in high-performance lab furnaces and equipment, ensuring a perfect fit for your spatial and technical requirements.

Contact KINTEK today to find the ideal heating solution for your laboratory. Our experts will help you select equipment that guarantees safety, efficiency, and longevity for your specific application.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding