For high-temperature applications, the primary materials of choice are specialized refractory metals, advanced ceramics, and carbon-based materials like graphite. These materials are selected for their ability to maintain structural integrity and chemical stability when subjected to extreme heat in processes like sintering, metal hardening, or aerospace propulsion.

The best high-temperature material is not simply the one with the highest melting point. The decision is a critical trade-off between thermal stability, mechanical strength at temperature, and chemical resistance to the specific operating atmosphere.

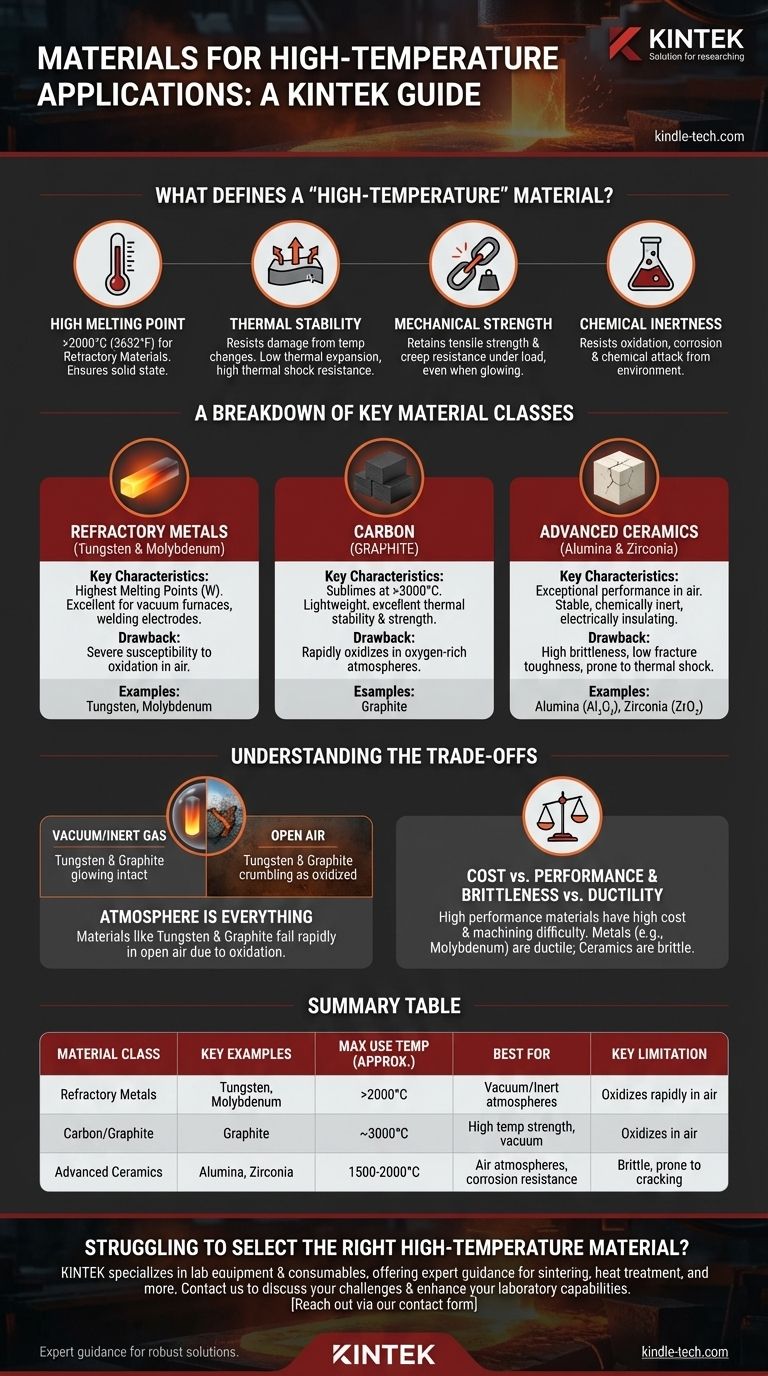

What Defines a "High-Temperature" Material?

To be effective at high temperatures, a material must possess a specific combination of properties. The absence of even one of these can lead to catastrophic failure.

High Melting Point

This is the most fundamental requirement. Materials with exceptionally high melting points, typically above 2000°C (3632°F), are known as refractory materials. This intrinsic property ensures the material remains in a solid state.

Thermal Stability

A material must resist damage from temperature changes. Key factors include low thermal expansion to prevent warping and high thermal shock resistance to avoid cracking during rapid heating or cooling cycles.

Mechanical Strength at Temperature

Many materials that are strong at room temperature become soft and weak when heated. High-temperature materials must retain their tensile strength and creep resistance (resistance to slow deformation) under load, even when glowing hot.

Chemical Inertness

High temperatures dramatically accelerate chemical reactions. The ideal material must resist oxidation, corrosion, and chemical attack from its surrounding environment, whether that is open air, a specific gas, or a vacuum.

A Breakdown of Key Material Classes

Different applications demand different material properties. The three most common classes each offer a unique profile of strengths and weaknesses.

Refractory Metals (Tungsten & Molybdenum)

As referenced, tungsten and molybdenum are workhorses for extreme heat. Tungsten has the highest melting point of any metal, making it ideal for vacuum furnace heating elements and welding electrodes.

Their primary drawback is a severe susceptibility to oxidation at high temperatures in the presence of air. This limits their use to vacuum or inert gas atmospheres.

Carbon (Graphite)

Graphite does not melt at atmospheric pressure but instead sublimes at extremely high temperatures (around 3652°C / 6606°F). It is lightweight and exhibits excellent thermal stability and strength at temperature.

Like refractory metals, graphite's critical weakness is oxidation. It will rapidly burn away in an oxygen-rich atmosphere, restricting its use to vacuum or inert environments for applications like furnace linings and sintering trays.

Advanced Ceramics (Alumina & Zirconia)

Materials like Alumina (Al₂O₃) and Zirconia (ZrO₂) offer exceptional performance in air. They are extremely stable at high temperatures, chemically inert, and electrically insulating.

However, their defining characteristic is their brittleness. Ceramics have very low fracture toughness, meaning they can crack and shatter under mechanical or thermal shock, which requires careful engineering and design.

Understanding the Trade-offs

Choosing the right material is an exercise in managing compromises. The perfect material rarely exists; instead, you must select the one whose weaknesses are acceptable for your specific application.

Atmosphere is Everything

This is the most common point of failure. A material that is a top performer in a vacuum, like tungsten or graphite, will be destroyed in minutes when operated at the same temperature in open air due to oxidation.

Cost vs. Performance

High-performance materials come with a high price tag. The cost of raw materials and the difficulty of machining hard, brittle substances like tungsten or ceramics can be significant factors in any project.

Brittleness vs. Ductility

Metals like molybdenum tend to be ductile, meaning they bend or deform before breaking. Ceramics are brittle and fail suddenly. This distinction has profound implications for component design, safety margins, and failure analysis.

Making the Right Choice for Your Goal

Your specific operating environment and performance goals will dictate the best material choice.

- If your primary focus is the absolute highest temperature in a vacuum or inert gas: Tungsten and graphite are the clear choices due to their unparalleled melting and sublimation points.

- If your primary focus is high-temperature strength and oxidation resistance in air: Nickel-based superalloys (for metal properties) or advanced ceramics like Zirconia are superior options.

- If your primary focus is wear resistance and chemical inertness in a hot, corrosive environment: Advanced ceramics like Alumina provide unmatched stability and hardness.

Ultimately, selecting the right material depends on a clear understanding of your specific thermal, mechanical, and atmospheric challenges.

Summary Table:

| Material Class | Key Examples | Max Use Temperature (Approx.) | Best For | Key Limitation |

|---|---|---|---|---|

| Refractory Metals | Tungsten, Molybdenum | >2000°C | Vacuum/Inert atmospheres | Oxidizes rapidly in air |

| Carbon/Graphite | Graphite | ~3000°C | High temp strength, vacuum | Oxidizes in air |

| Advanced Ceramics | Alumina, Zirconia | 1500-2000°C | Air atmospheres, corrosion resistance | Brittle, prone to cracking |

Struggling to select the right high-temperature material for your lab's demanding processes? KINTEK specializes in lab equipment and consumables, offering expert guidance and robust solutions for sintering, heat treatment, and more. Our team can help you navigate material trade-offs to ensure optimal performance, safety, and cost-efficiency. Contact us today to discuss your specific high-temperature challenges and discover how our expertise can enhance your laboratory's capabilities. Reach out via our contact form for a personalized consultation!

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does brazing work? Create Strong, Permanent Metal Joints with Metallurgical Bonding

- What materials are sintered steel? Unlock the Secrets of Powder-Based Steel Manufacturing

- What are some examples of where brazing is used? Join Dissimilar Metals with High-Strength, Leak-Proof Joints

- What is the use of furnace in a laboratory? Essential Tool for Material Transformation

- How much does pyrolysis oil cost? A Guide to Pricing Based on Quality and Application

- What is the function of a temperature-controlled drying oven in the Sol-Gel process? Ensure Defect-Free Membranes

- How does the stirring speed affect silver nanowires morphology? Master Agitation for High-Purity Synthesis

- What is the difference between sintering and melting temperature? Choosing the Right Thermal Process for Your Materials