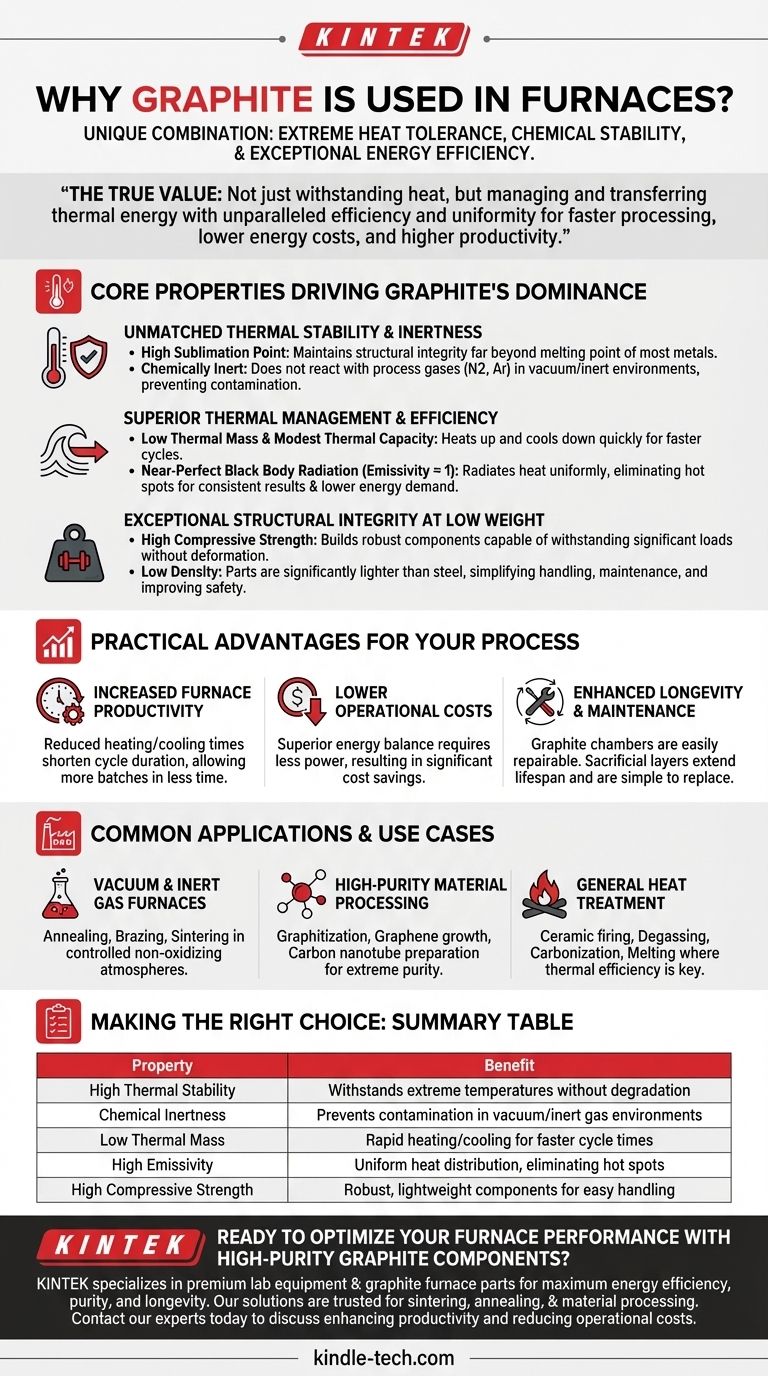

At its core, graphite is used in furnaces because it possesses a unique combination of extreme heat tolerance, chemical stability, and exceptional energy efficiency that few other materials can match. Its ability to perform reliably in high-temperature, vacuum, or inert gas environments makes it an indispensable component for demanding industrial processes.

The true value of graphite in a furnace is not just its ability to withstand heat, but its power to manage and transfer thermal energy with unparalleled efficiency and uniformity. This results in faster processing, lower energy costs, and higher productivity.

The Core Properties Driving Graphite's Dominance

To understand why graphite is so prevalent, we must look at its fundamental material properties. It isn't just one characteristic, but the synergy between several that makes it the superior choice for furnace construction and components.

Unmatched Thermal Stability and Inertness

Graphite has an extremely high sublimation point, allowing it to maintain its structural integrity at temperatures far beyond the melting point of most metals.

Critically, in vacuum or controlled atmosphere furnaces, graphite is chemically inert. It does not react with process gases like nitrogen and argon, preventing contamination of the workpieces being treated.

Superior Thermal Management and Efficiency

Graphite has a relatively low thermal mass and modest thermal capacity. This means it heats up and cools down very quickly, reducing the time required for each furnace cycle.

Furthermore, graphite exhibits near-perfect black body radiation conditions, with an emissivity close to 1. This ensures that heat is radiated uniformly throughout the furnace chamber, eliminating hot spots and providing consistent results. This combination of properties leads directly to lower overall energy demand.

Exceptional Structural Integrity at Low Weight

Despite being lightweight, graphite has very high compressive strength. This allows for the construction of robust furnace components that can withstand significant loads without deforming.

The low density of graphite makes furnace parts significantly lighter than comparable steel racks or elements. This simplifies handling, facilitates easier maintenance cycles, and contributes to a safer working environment.

Understanding the Practical Advantages

These fundamental properties translate directly into tangible operational benefits that impact efficiency, cost, and longevity.

Increased Furnace Productivity

Because graphite allows for reduced heating and cooling times, the overall duration of each work cycle is shorter. This allows operators to process more batches in the same amount of time, directly increasing furnace productivity.

Lower Operational Costs

The superior energy balance provided by graphite components means less power is required to reach and maintain target temperatures. This energy efficiency results in significant cost savings over the life of the furnace.

Enhanced Longevity and Maintenance

Graphite furnace chambers are known for being easily repairable. To further extend their lifespan, they can be protected with sacrificial layers, which are simpler and cheaper to replace than the entire chamber lining.

Common Applications and Use Cases

Graphite's unique characteristics make it ideal for a wide range of high-temperature applications where precision and purity are critical.

Vacuum and Inert Gas Furnaces

Its non-reactivity makes graphite the go-to material for processes like annealing, brazing, and sintering that must be conducted in a controlled, non-oxidizing atmosphere to protect the workpiece.

High-Purity Material Processing

Graphite furnaces are essential in fields requiring extreme purity and temperature control, such as graphitization, graphene growth, and the preparation of carbon nanotubes.

General Heat Treatment

The material is also widely used for general processes including ceramic firing, degassing, carbonization, and melting, where its thermal efficiency and stability are highly valued.

Making the Right Choice for Your Process

Selecting the right material is a strategic decision based on the specific goals of your thermal application.

- If your primary focus is maximum energy efficiency and speed: Graphite's low thermal mass and high emissivity are ideal for achieving rapid, uniform heating and cooling cycles.

- If your primary focus is process purity in a vacuum: The chemical inertness of graphite at extreme temperatures is essential to prevent contamination of sensitive materials.

- If your primary focus is operational safety and ease of handling: The low density and high strength of graphite components reduce physical strain and accident risk compared to heavier metal alternatives.

Ultimately, using graphite is a deliberate choice to optimize performance, efficiency, and reliability in the most demanding thermal environments.

Summary Table:

| Property | Benefit |

|---|---|

| High Thermal Stability | Withstands extreme temperatures without degradation |

| Chemical Inertness | Prevents contamination in vacuum/inert gas environments |

| Low Thermal Mass | Rapid heating/cooling for faster cycle times |

| High Emissivity | Uniform heat distribution, eliminating hot spots |

| High Compressive Strength | Robust, lightweight components for easy handling |

Ready to optimize your furnace performance with high-purity graphite components? KINTEK specializes in premium lab equipment and consumables, including graphite furnace parts designed for maximum energy efficiency, process purity, and longevity. Our solutions are trusted by laboratories for applications like sintering, annealing, and material processing. Contact our experts today to discuss how our graphite solutions can enhance your productivity and reduce operational costs.

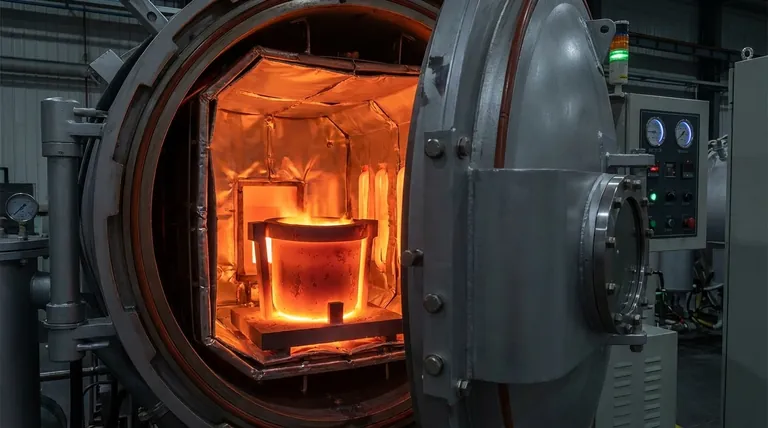

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- Does graphite have a melting point? Unlocking the Extreme Heat Resistance of Graphite

- What is the temperature range of a graphite furnace? Unlock up to 3000°C for advanced materials processing.

- What is the purpose of a graphite furnace? Achieve Extreme Temperatures for Advanced Materials

- What are the applications of graphite material? Leveraging Extreme Heat and Precision for Industrial Processes

- Can graphite withstand heat? Unlocking its extreme 3,600°C potential in inert environments