The short answer is that hydraulic press machines use a specialized hydraulic fluid, not a generic motor oil or lubricant. In most industrial applications, this is a mineral oil-based fluid with an ISO Viscosity Grade (VG) of 46 and an anti-wear (AW) additive package.

The specific oil is less important than its properties. The correct choice is always a hydraulic fluid with the precise viscosity and additive package recommended by the machine's manufacturer to handle the system's operating pressure, temperature, and speed.

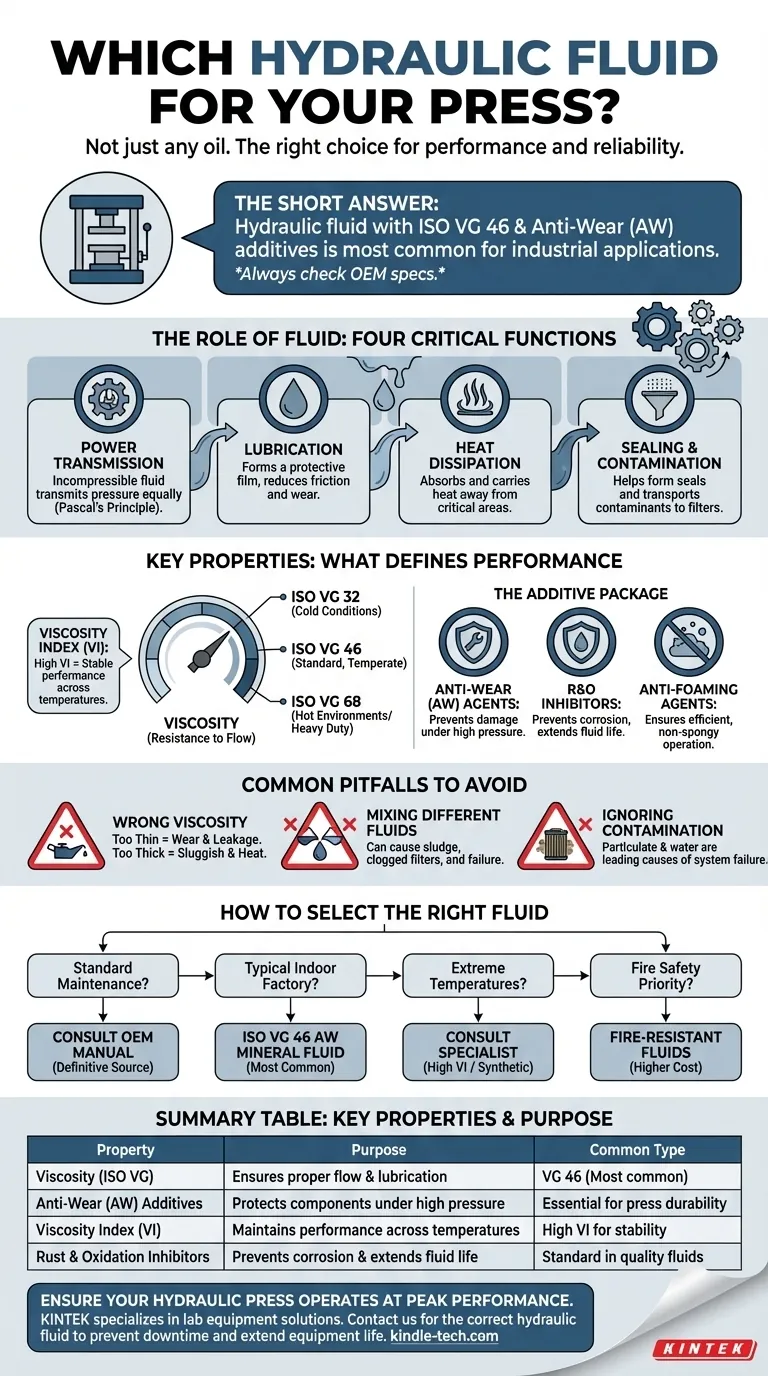

The Role of Fluid in a Hydraulic Press

Understanding why a specific fluid is used is crucial for machine reliability and performance. The fluid is the lifeblood of the system, performing four critical functions simultaneously.

Power Transmission

This is the fluid's primary job. Because liquids are largely incompressible, when force is applied by a pump, the fluid transmits that pressure equally throughout the system, activating the press ram according to Pascal's Principle.

Lubrication

The fluid forms a protective film between moving metal parts, especially within the hydraulic pump and cylinders. This lubrication is essential to prevent friction, reduce wear, and extend the life of expensive components.

Heat Dissipation

As the press operates, mechanical and fluid friction generates significant heat. The hydraulic fluid absorbs this heat from critical areas and carries it to the reservoir or a heat exchanger to be dissipated, preventing the system from overheating.

Sealing and Contamination Control

The fluid helps form seals within components like pumps and valves. It also acts as a carrier, transporting contaminants like metal particles or dirt to the system's filters, where they can be safely removed.

Key Properties of Hydraulic Fluid

Not all hydraulic fluids are created equal. Their performance is defined by a few key characteristics that must match the demands of the machine.

Viscosity: The Most Critical Factor

Viscosity is a measure of a fluid's resistance to flow. It is the single most important property of a hydraulic fluid.

It is typically defined by an ISO Viscosity Grade (VG), such as ISO VG 32, VG 46, or VG 68. A higher number indicates a thicker, more viscous fluid.

- ISO VG 46 is the most common grade for industrial presses in temperate environments.

- ISO VG 32 may be used in colder conditions for better flow on startup.

- ISO VG 68 is often specified for hotter environments or heavy-duty cycles.

Viscosity Index (VI)

This value indicates how much the fluid's viscosity changes with temperature. A high Viscosity Index (VI) is desirable, as it means the fluid maintains stable performance whether the machine is starting cold or running hot.

The Additive Package

Base oils are enhanced with chemical additives to improve performance and protect the hydraulic system.

- Anti-Wear (AW) Agents: These are vital. They form a sacrificial layer on metal surfaces to prevent damage under the extreme pressures found in a hydraulic press.

- Rust & Oxidation (R&O) Inhibitors: These additives prevent corrosion of metal components and slow the chemical breakdown of the oil itself, extending its service life.

- Anti-Foaming Agents: Foam can make the fluid compressible, leading to spongy, inefficient operation. These additives help air bubbles break up and dissipate quickly.

Common Pitfalls to Avoid

Choosing the wrong fluid or improper maintenance can lead to costly failures. Understanding these common mistakes is essential for any operator.

Using the Wrong Viscosity

This is the most frequent and damaging error.

- Too Low (Too Thin): Leads to poor lubrication, increased internal leakage, and component wear.

- Too High (Too Thick): Causes sluggish operation, increased energy consumption, and excessive heat generation.

Mixing Different Fluid Types

Never mix different types or brands of hydraulic fluid unless you are certain they are compatible. The additive packages can react negatively with each other, causing sludge, clogged filters, and a complete loss of performance.

Ignoring Contamination

Particulate and water contamination are the leading causes of hydraulic system failure. Always use clean transfer equipment, ensure filters are in good condition, and keep the reservoir sealed to protect the fluid's integrity.

How to Select the Right Fluid for Your Press

Always prioritize the manufacturer's specifications. If that information is unavailable, these guidelines will help you make an informed decision.

- If you are performing standard maintenance: Always consult the machine’s OEM (Original Equipment Manufacturer) manual. This is the definitive source for the correct fluid type and viscosity grade.

- If you operate in a typical indoor factory: An ISO VG 46 mineral-based fluid with an anti-wear (AW) additive package is the most common and reliable choice.

- If your press operates in extreme temperatures: Consult a fluid specialist to select a high Viscosity Index (VI) or a synthetic fluid that remains stable across your full operating range.

- If fire safety is your absolute priority: Investigate specialized fire-resistant fluids, but be prepared for higher costs and potential differences in lubrication performance.

Choosing the correct hydraulic fluid is a critical maintenance decision that directly impacts your machine's efficiency, reliability, and lifespan.

Summary Table:

| Property | Purpose | Common Type |

|---|---|---|

| Viscosity (ISO VG) | Ensures proper flow and lubrication | VG 46 (most common) |

| Anti-Wear (AW) Additives | Protects components under high pressure | Essential for press durability |

| Viscosity Index (VI) | Maintains performance across temperatures | High VI for stability |

| Rust & Oxidation Inhibitors | Prevents corrosion and extends fluid life | Standard in quality fluids |

Ensure your hydraulic press operates at peak performance with the right fluid.

KINTEK specializes in lab equipment and consumables, providing reliable solutions for laboratories that rely on hydraulic presses for material testing, sample preparation, and R&D. Our expertise ensures you select the correct hydraulic fluid to prevent downtime, reduce wear, and extend the life of your equipment.

Contact us today for personalized recommendations and high-quality hydraulic fluids tailored to your specific press and operating conditions.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability