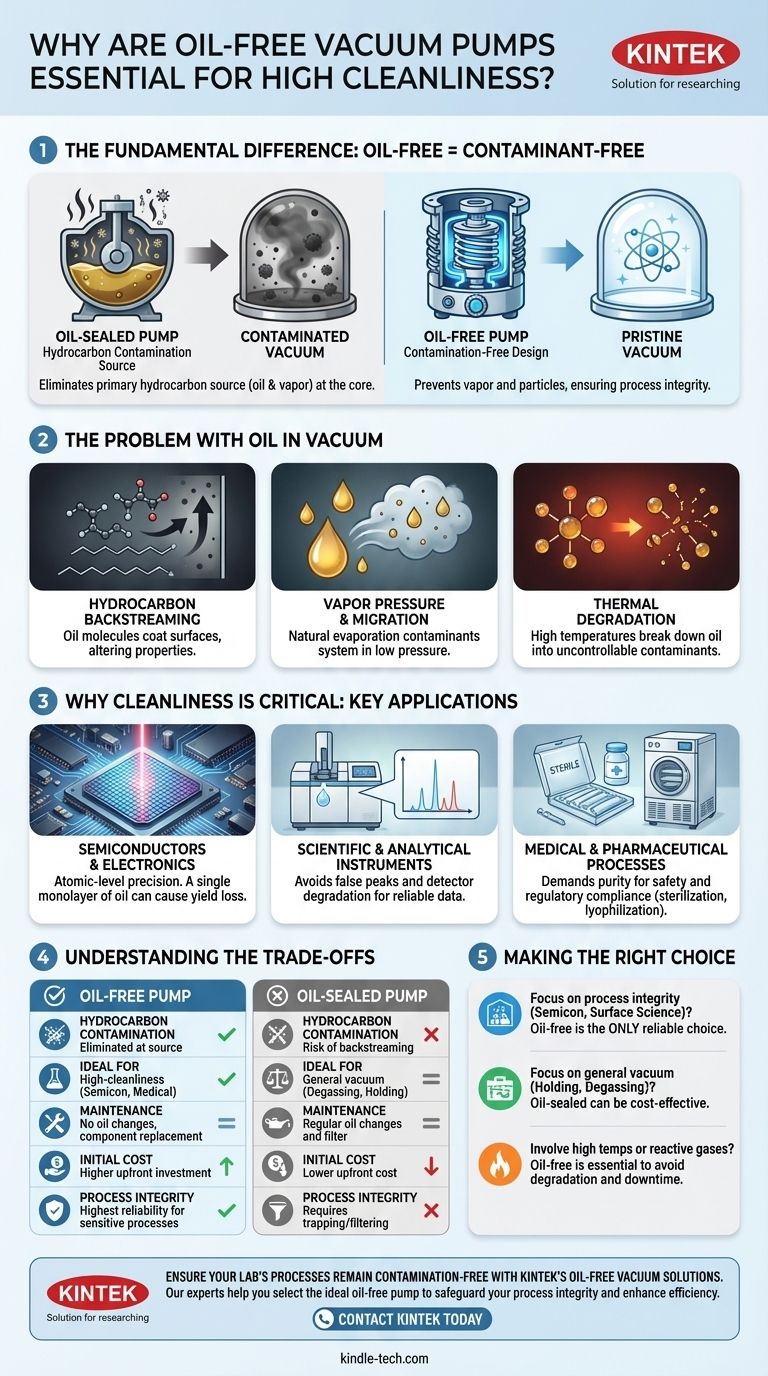

To put it simply, oil-free vacuum pumps are suitable for high-cleanliness applications because they fundamentally eliminate the primary source of hydrocarbon contamination: lubricating and sealing oil. This design prevents oil vapor and particles from entering the vacuum environment, a critical requirement for sensitive processes where even microscopic contaminants can ruin products or invalidate results.

The decision to use an oil-free pump is about risk mitigation. While oil-sealed pumps can be trapped and filtered, oil-free designs remove the contaminant at its source, providing a more reliable and failsafe solution for applications where process integrity is non-negotiable.

The Problem with Oil in a Vacuum

To appreciate the value of oil-free pumps, you must first understand why oil is so problematic in a clean vacuum system. The issue goes beyond simple liquid leaks.

Hydrocarbon Contamination

Vacuum pump oil is composed of long-chain hydrocarbons. In a vacuum, these molecules can migrate into your chamber and coat every surface, a phenomenon often called backstreaming.

Vapor Pressure and Migration

Every material has a vapor pressure, meaning it will naturally turn into a gas. In the low-pressure environment of a vacuum, oil's vapor pressure causes it to evaporate and travel freely throughout the system, contaminating your process even if the pump is working perfectly.

The Impact of Thermal Degradation

In high-temperature applications, such as metal heat treatment or chemical vapor deposition, heat can cause oil molecules to "crack" or break down. This creates a wide range of lighter, more mobile contaminants that are even harder to control and can interfere with surface chemistry.

Why Cleanliness is Critical: Key Applications

For many advanced industries, a hydrocarbon-free environment is not a preference; it is a strict requirement for success.

Semiconductor and Electronics Manufacturing

Processes like thin-film deposition and etching require atomic-level precision. A single monolayer of oil contamination on a silicon wafer can block the process, altering electrical properties and causing the entire device to fail. This makes oil-free operation essential for maintaining production yield.

Scientific and Analytical Instruments

In research tools like mass spectrometers, particle accelerators, and electron microscopes, oil contamination is catastrophic. Hydrocarbon molecules can create false data peaks, obscure samples under analysis, and degrade sensitive detectors, rendering experimental results useless.

Medical and Pharmaceutical Processes

Applications such as sterilization, freeze-drying (lyophilization), and sterile packaging demand an absolutely pure environment. Any contamination from pump oil can compromise the safety and efficacy of the final medical product, creating significant regulatory and health risks.

Understanding the Trade-offs

While superior for cleanliness, oil-free pumps are not a universal solution. Acknowledging their trade-offs is key to making an informed decision.

Higher Initial Cost

Oil-free pumps, such as dry scroll, diaphragm, turbomolecular, or ion pumps, generally have a higher upfront purchase price than their traditional oil-sealed rotary vane counterparts.

Different Maintenance Profiles

Oil-free pumps eliminate messy oil changes. However, they are not maintenance-free. Components like tip seals in scroll pumps or bearings in turbomolecular pumps are wear items that require periodic replacement, which can be more complex and costly than servicing an oil pump.

Specific Performance Characteristics

An oil-sealed pump may offer a better cost-to-performance ratio for achieving certain vacuum levels or pumping speeds. The correct choice always depends on the specific pressure range and gas load of your application, not just the need for cleanliness.

Making the Right Choice for Your Goal

Your application's tolerance for contamination should be the deciding factor.

- If your primary focus is process integrity in semiconductors or surface science: An oil-free system is the only reliable choice to prevent yield loss and ensure data accuracy.

- If your primary focus is general vacuum work like mechanical holding or degassing non-sensitive materials: A properly trapped and maintained oil-sealed pump is a highly cost-effective solution.

- If your process involves high temperatures, reactive gases, or long run times: An oil-free pump is essential to avoid contamination from oil degradation and minimize maintenance downtime.

Ultimately, selecting an oil-free pump is an investment in the predictability and purity of your vacuum environment.

Summary Table:

| Feature | Oil-Free Vacuum Pump | Oil-Sealed Vacuum Pump |

|---|---|---|

| Hydrocarbon Contamination | Eliminated at source | Risk of backstreaming and vapor migration |

| Ideal For | High-cleanliness applications (e.g., semiconductors, medical) | General vacuum work (e.g., degassing, holding) |

| Maintenance | No oil changes; periodic component replacement | Regular oil changes and filter maintenance |

| Initial Cost | Higher | Lower |

| Process Integrity | Highest reliability for sensitive processes | Requires trapping/filtering for clean applications |

Ensure your lab's processes remain contamination-free with KINTEK's oil-free vacuum solutions.

Whether you're in semiconductor manufacturing, pharmaceutical research, or analytical instrumentation, our oil-free pumps are engineered to deliver the pristine vacuum environment your work demands. By eliminating hydrocarbon contamination at the source, we help you protect product yield, ensure data accuracy, and meet stringent regulatory standards.

Contact KINTEK today to discuss your specific application needs. Our experts will help you select the ideal oil-free vacuum pump to safeguard your process integrity and enhance your lab's efficiency.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Variable Speed Peristaltic Pump

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- Why are quartz sleeves utilized to protect thermocouples during high-temperature corrosion testing? Ensure Data Accuracy

- What are furnaces usually made of? A Guide to Materials for Extreme Temperatures

- What temperature does a rotary vane vacuum pump run at? Ensure Optimal Performance and Longevity

- What key roles do needle valves and precision gas systems play? Achieve Perfect Plasma Nitriding Atmospheres

- How does quartz differ from glass? A Guide to Material Selection for Performance

- What temperature can quartz tube withstand? Up to 1200°C for Peak Performance & Reliability

- What are the impurities in quartz? Unlocking the Secrets of Color and Performance

- Why are high-purity alumina ceramic boats required for FeCrAl oxidation? Ensure Data Integrity at 1200°C+