In essence, press machines are preferred for their unparalleled combination of speed, precision, and cost-effectiveness in high-volume production. They are the engines of modern manufacturing, capable of transforming raw material into finished parts in a single, powerful stroke. This ability to perform repetitive forming, stamping, and punching operations with extreme consistency makes them the default choice for producing a vast range of everyday items, from automotive body panels to electronic components.

The core reason for the prevalence of press machines is economic: they dramatically lower the cost-per-part for mass-produced items. While the initial investment in the machine and its tooling is high, this cost is amortized over millions of cycles, making them the most efficient method for large-scale manufacturing.

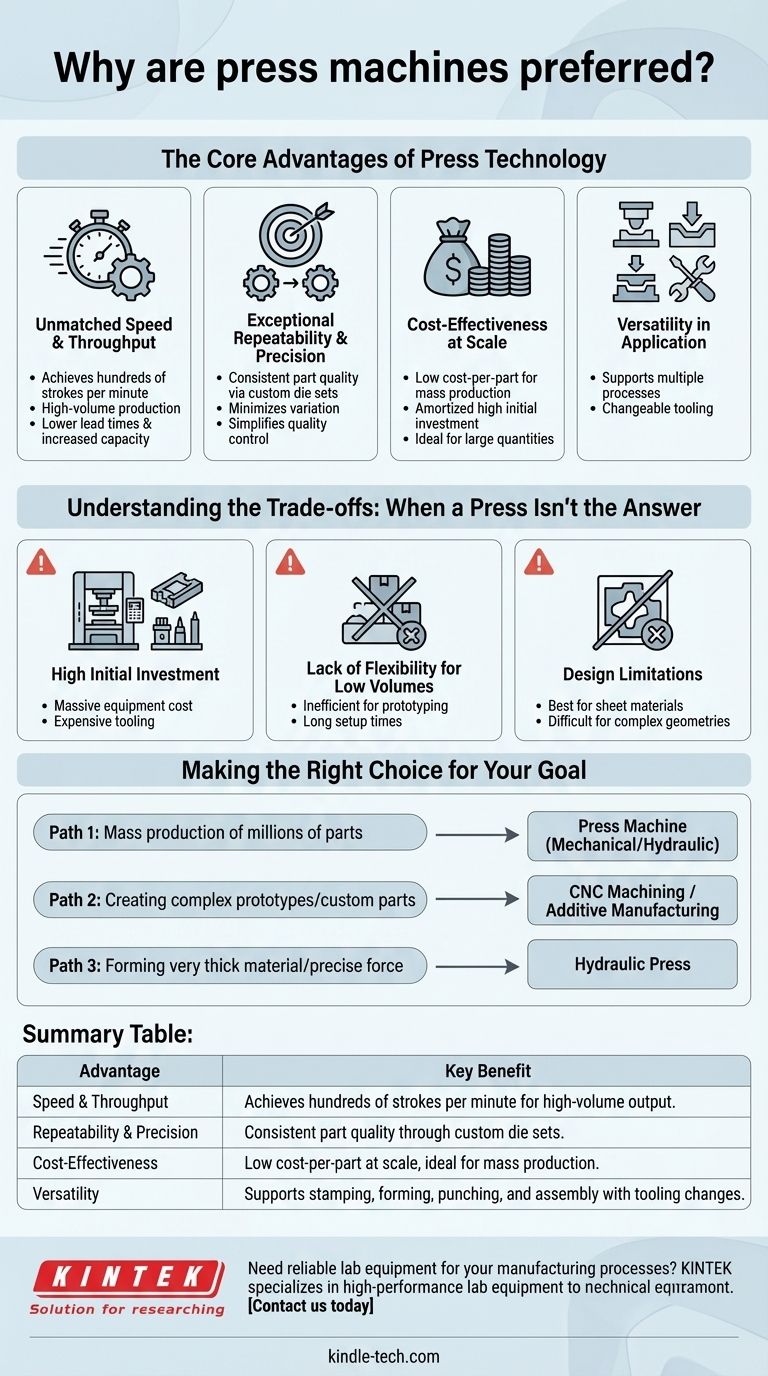

The Core Advantages of Press Technology

To understand why presses dominate many manufacturing floors, we must look at their fundamental operational benefits. These advantages create a powerful business case for any application involving high-volume, repeatable shaping of materials.

Unmatched Speed and Throughput

A press machine's operation is cyclical. Once set up, it can run continuously, with some mechanical presses achieving hundreds of strokes per minute. This rapid, rhythmic action allows for a production output that is difficult for other processes, like CNC machining, to match.

For mass production, higher throughput directly translates to lower lead times and increased capacity.

Exceptional Repeatability and Precision

The precision of a pressed part comes not from the press itself, but from the die set—the custom tooling that shapes the material. Because the die's geometry is fixed, every part it produces is a near-perfect replica of the one before it.

This inherent consistency minimizes part-to-part variation, simplifying quality control and ensuring components fit together flawlessly in downstream assembly operations.

Cost-Effectiveness at Scale

The economic model of press work is simple: high initial cost for low per-piece cost. The design and fabrication of a hardened steel die set can be expensive, but this is a one-time capital expense.

When that cost is spread across hundreds of thousands or millions of parts, the tooling cost per part becomes negligible. This makes press-forming exceptionally cost-effective for consumer goods, automotive parts, and any item produced in large quantities.

Versatility in Application

Presses are not limited to one type of operation. By simply changing the tooling, the same machine can be used for a wide range of processes, including:

- Stamping and Punching: Creating holes or blanking out shapes from sheet metal.

- Forming and Drawing: Bending or stretching a metal sheet into a 3D shape, like a sink basin.

- Coining: Applying immense pressure to create detailed surface features, like those on a coin.

- Assembly: Press-fitting components like bearings or pins together.

Understanding the Trade-offs: When a Press Isn't the Answer

Despite their advantages, press machines are not a universal solution. Their primary strength—specialization for high volume—is also their primary weakness. Understanding these limitations is crucial for making sound engineering decisions.

High Initial Investment

The upfront cost is the single biggest barrier. This includes not only the press machine itself, which can be a massive piece of equipment, but also the highly specific and expensive tooling. For a new product, this represents a significant financial risk before a single part is sold.

Lack of Flexibility for Low Volumes

Presses are incredibly inefficient for prototyping or small production runs. The time and cost required to create a die set make them completely impractical for producing a handful of parts. The long setup times for installing and aligning heavy dies also work against small-batch production.

Design Limitations

While versatile, press forming works best with sheet materials and relatively simple geometries. Highly complex, intricate shapes with undercuts or internal features are often impossible to form in a die. For such designs, processes like CNC machining, casting, or 3D printing are far better suited.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process requires aligning the technology's strengths with your project's primary objective. The choice is rarely about which process is "best," but which is most appropriate for the job at hand.

- If your primary focus is mass production of millions of identical parts: A press machine, whether mechanical for speed or hydraulic for force, is almost certainly the most efficient and cost-effective solution.

- If your primary focus is creating a few complex prototypes or custom parts: CNC machining or additive manufacturing (3D printing) offers superior design freedom and avoids the prohibitive cost of press tooling.

- If your primary focus is forming very thick material or requiring precise force control throughout the stroke: A hydraulic press provides the raw power and control that a mechanical press may lack.

Ultimately, a press machine is a specialized tool that excels when its power is leveraged against the challenge of scale.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Throughput | Achieves hundreds of strokes per minute for high-volume output. |

| Repeatability & Precision | Consistent part quality through custom die sets. |

| Cost-Effectiveness | Low cost-per-part at scale, ideal for mass production. |

| Versatility | Supports stamping, forming, punching, and assembly with tooling changes. |

Need reliable lab equipment for your manufacturing processes? KINTEK specializes in high-performance lab equipment and consumables, serving laboratories that require precision and efficiency. Whether you're testing materials or scaling production, our solutions enhance accuracy and throughput. Contact us today to explore how KINTEK can support your lab's success with tailored equipment solutions!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis