At their core, pressure switches are indispensable components because they act as simple, automated sentinels for any system involving pressurized fluids or gases. They function as a crucial bridge between the physical world of pressure and the electrical world of control, automatically triggering an action—like turning a pump on, shutting a valve, or sounding an alarm—when a specific pressure level is reached.

The true importance of a pressure switch is not what it is (a mechanical switch), but what it enables: reliable automation, critical safety interlocks, and process efficiency, often without the need for complex and expensive electronic controllers.

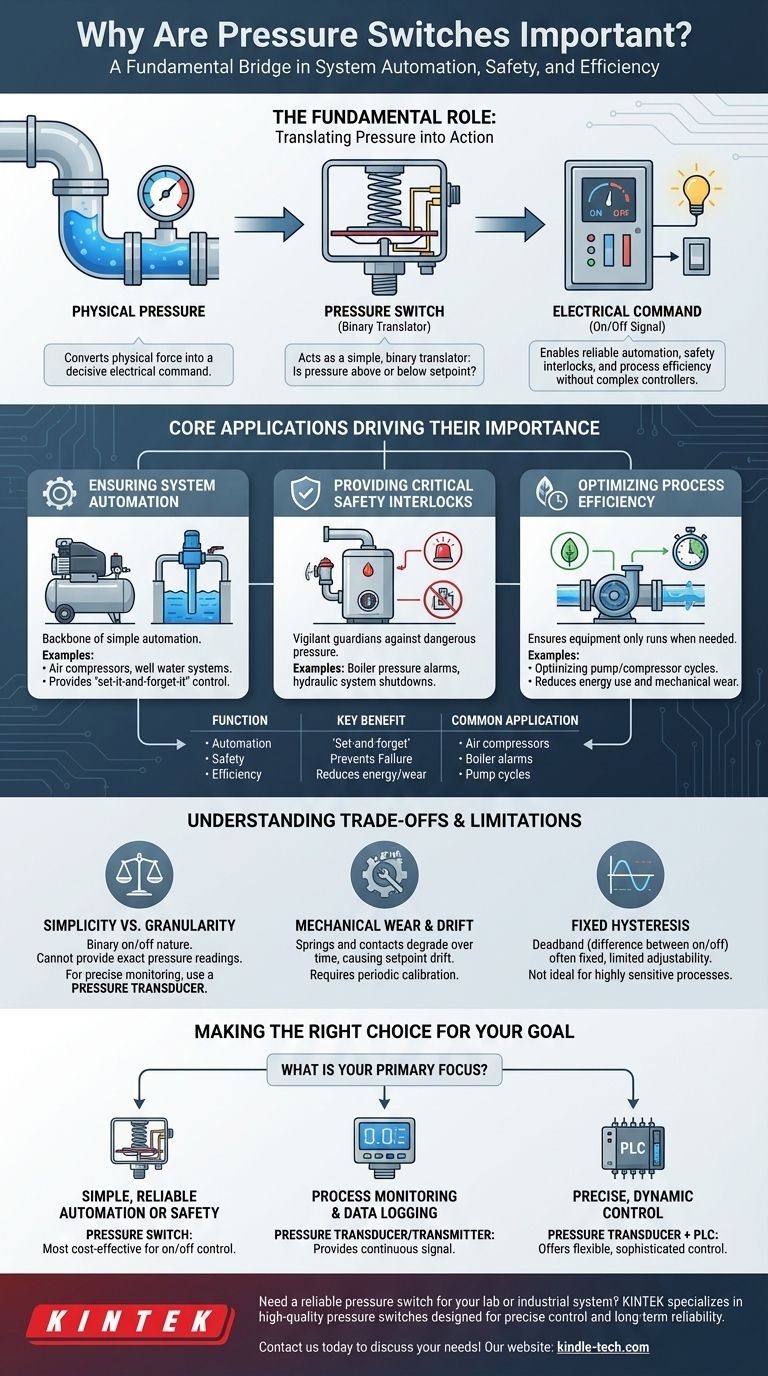

The Fundamental Role: Translating Pressure into Action

A pressure switch is a remarkably straightforward device that performs a critical task. Its importance is rooted in its ability to convert a physical force into a decisive electrical command.

How a Pressure Switch Works

A pressure switch contains a sensing element, such as a diaphragm or piston, which is exposed to the system's fluid pressure. This element pushes against a pre-calibrated spring.

When the force exerted by the fluid pressure overcomes the opposing force of the spring, it causes a set of electrical contacts to either open or close, completing or breaking a circuit.

The specific pressure at which this happens is the setpoint. The pressure at which it resets is determined by its deadband or differential, preventing the switch from rapidly cycling on and off.

The Bridge Between Mechanical and Electrical Worlds

Think of a pressure switch as a simple, binary translator. It doesn't measure the specific pressure value like a gauge or transducer does.

Instead, it answers a single, vital question: "Is the pressure above or below my setpoint?" Based on the answer, it provides a definitive on/off electrical signal. This simplicity is its greatest strength.

Core Applications Driving Their Importance

The value of a pressure switch is most evident in its three primary functions across countless industrial, commercial, and residential applications.

Ensuring System Automation

Pressure switches are the backbone of simple automation. A classic example is a well water system, where a pressure switch turns the pump on when pressure drops (from a faucet being opened) and turns it off once the pressure tank is refilled.

Similarly, an air compressor uses a pressure switch to start the motor when tank pressure is low and stop it when it reaches the desired PSI. This provides "set-it-and-forget-it" control without human intervention.

Providing Critical Safety Interlocks

In many systems, operating outside a safe pressure range can lead to catastrophic failure. Pressure switches act as vigilant guardians.

For instance, a switch can shut down a machine if hydraulic pressure drops too low, preventing damage from lack of lubrication. Conversely, it can trigger a relief valve or alarm if boiler pressure climbs dangerously high, preventing an explosion.

Optimizing Process Efficiency

By ensuring equipment only runs when needed, pressure switches are key to energy efficiency and longevity.

A compressor or pump that only activates to maintain a set pressure consumes significantly less power than one that runs continuously. This also reduces mechanical wear and tear, extending the operational life of expensive components and lowering maintenance costs.

Understanding the Trade-offs and Limitations

While incredibly useful, pressure switches are not the solution for every scenario. Understanding their limitations is key to using them correctly.

Simplicity vs. Granularity

The binary on/off nature of a pressure switch is its biggest advantage but also a limitation. It cannot tell you the exact pressure is 87 PSI; it can only tell you it's above or below your 100 PSI setpoint.

For applications requiring precise pressure monitoring, data logging, or variable control, a pressure transducer or transmitter—which provides a continuous analog or digital signal—is the appropriate device.

Mechanical Wear and Setpoint Drift

As mechanical devices with springs and moving contacts, pressure switches are subject to wear over time. The spring can lose tension and the contacts can degrade from electrical arcing.

This can cause the activation point (setpoint drift) to shift, requiring periodic inspection and recalibration to ensure the system remains protected and efficient.

Fixed Hysteresis

The pressure difference between the on and off points (the deadband or hysteresis) is often built into the switch and may have limited or no adjustability.

In highly sensitive processes where the gap between on and off must be tightly controlled, the fixed deadband of a standard switch may not be sufficient.

Making the Right Choice for Your Goal

The decision to use a pressure switch versus a more advanced sensor depends entirely on the complexity and requirements of your system.

- If your primary focus is simple, reliable automation or safety: A pressure switch is often the most cost-effective and robust solution for on/off control.

- If your primary focus is process monitoring and data logging: You need a pressure transducer or transmitter that provides a continuous analog or digital signal to a display or controller.

- If your primary focus is precise, dynamic control: A pressure transducer paired with a PLC or other controller offers the flexibility needed for sophisticated process logic.

Ultimately, appreciating the function of the humble pressure switch is a foundational step toward designing more intelligent, safe, and efficient systems.

Summary Table:

| Function | Key Benefit | Common Application |

|---|---|---|

| Automation | Enables 'set-and-forget' control | Well water systems, air compressors |

| Safety | Prevents catastrophic failure | Boiler pressure alarms, hydraulic system shutdowns |

| Efficiency | Reduces energy use and wear | Optimizing pump and compressor cycles |

Need a reliable pressure switch for your lab or industrial system?

KINTEK specializes in high-quality lab equipment and consumables, including robust pressure switches designed for precise control and long-term reliability. Whether you're automating a process, ensuring safety, or optimizing efficiency, our solutions are tailored to meet your laboratory's specific needs.

Contact us today to discuss how KINTEK can enhance your system's performance and safety!

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance

- How does a laboratory stirrer influence MOF product quality? Master Precision in Non-Solvothermal Synthesis

- How does a high-efficiency stirring system address the technical challenges of solvent viscosity? Master Pretreatment.

- Why is a high-precision orbital shaker required for chitin adsorption? Achieve Rapid Equilibrium & Precise Data

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research