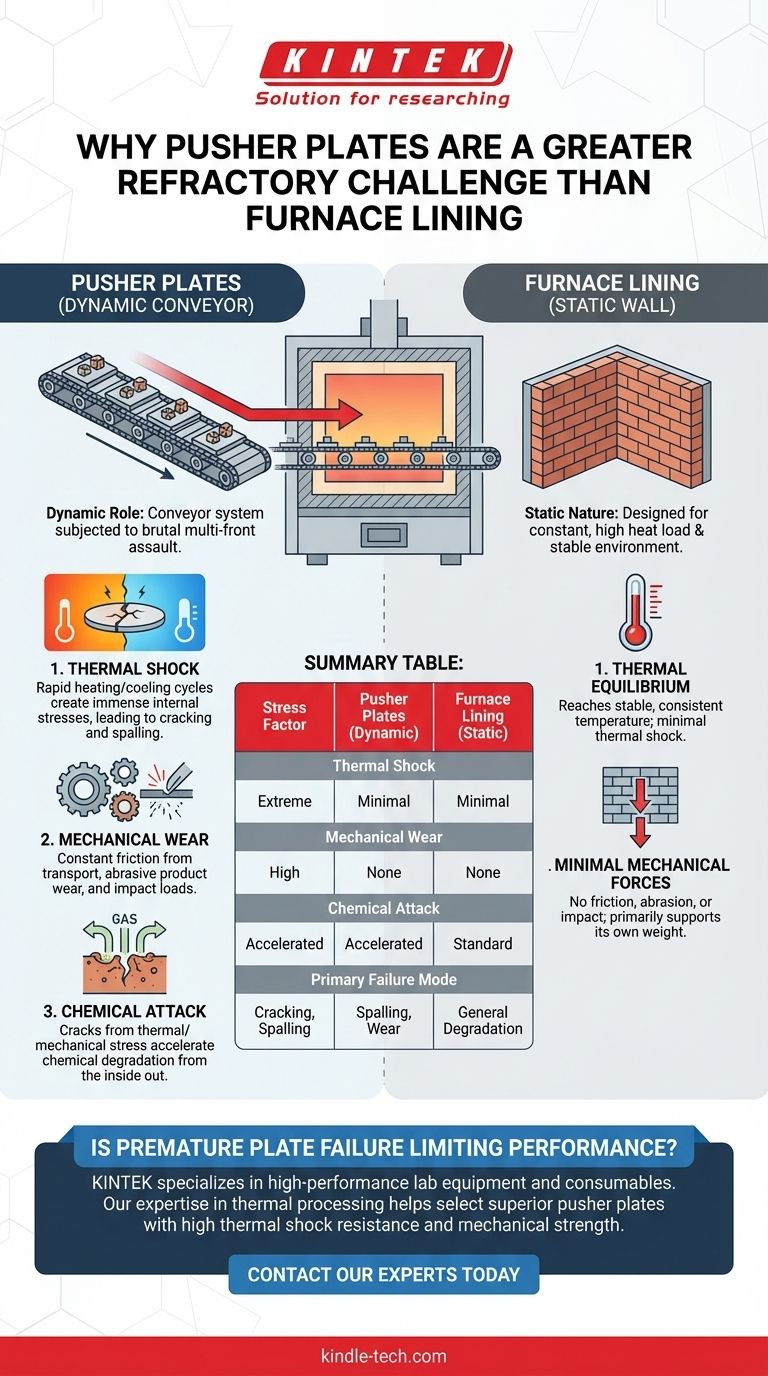

The fundamental reason pusher plates are a greater refractory challenge is their dynamic role within the furnace. Unlike the static furnace lining which endures a relatively stable high-temperature environment, the plates are a conveyor system subjected to a brutal and simultaneous combination of thermal shock, mechanical wear, and chemical attack.

The core issue is movement versus stability. A furnace lining is designed to withstand a constant, high heat load. A pusher plate, however, must survive a repeating cycle of extreme temperature changes, physical abrasion, and impact, making it the most vulnerable component in the system.

The Compounding Stresses on Pusher Plates

A pusher plate's job forces it to endure a multi-front assault that the furnace lining is completely shielded from. This combination of stresses is what leads to premature failure.

The Brutality of Thermal Shock

Thermal shock is the stress induced in a material by a rapid change in temperature. Pusher plates experience this in its most severe form.

They are heated to the furnace's maximum temperature and then can be rapidly moved into a much cooler quench zone. This causes the material's surface to contract violently while its core remains hot and expanded, generating immense internal stresses that lead to cracking and spalling.

Constant Mechanical Wear and Impact

As the core of the conveyor system, pusher plates are in constant motion. They are subject to significant mechanical stresses.

This includes abrasive wear from the product sliding across their surface, friction from the transport mechanism, and impact loads as new parts are introduced. The stationary furnace lining experiences none of these forces.

The Role of Chemical Attack

Both the lining and the plates are exposed to the furnace atmosphere and any chemical reactions from the product. However, the damage to the plates is accelerated.

The cracks and surface degradation caused by thermal shock and mechanical abrasion create more surface area. This gives corrosive gases a direct pathway deep into the material, significantly speeding up chemical degradation from the inside out.

The Stationary Advantage: Why Furnace Linings Endure

The furnace lining faces a much simpler set of challenges, allowing it to be optimized for a much longer service life. Its static nature is its greatest strength.

A State of Thermal Equilibrium

Once the furnace is at operating temperature, the lining reaches a stable thermal equilibrium. It is extremely hot, but the temperature is consistent.

This lack of rapid temperature cycling means it does not experience the destructive internal stresses of thermal shock.

An Absence of Mechanical Forces

The lining is a static wall. Its primary mechanical load is its own weight. It is not subject to the friction, abrasion, and impact that the pusher plates must constantly endure.

A Simpler Design Problem

Because the lining only needs to contend with high temperatures and potential chemical reactions, materials can be selected with a narrow focus. The primary goals are typically maximum temperature resistance and high insulating value.

The material for a pusher plate, by contrast, must be a difficult compromise between thermal shock resistance, high-temperature mechanical strength, and abrasion resistance. Optimizing for one of these properties often means sacrificing performance in another.

Key Considerations for Material Selection and Maintenance

Understanding these distinct failure modes is critical for improving the reliability of the entire furnace system. Your focus must be different for each component.

- If your primary focus is extending pusher plate life: Prioritize materials with exceptional thermal shock resistance and high hot-modulus of rupture (strength at temperature).

- If your primary focus is maximizing furnace lining longevity: Select materials with the highest possible service temperature rating and the best chemical compatibility with your process atmosphere.

- If your primary focus is overall system reliability: Implement a rigorous inspection schedule targeting the pusher plates, as they will almost certainly be the first components to show signs of wear and are the leading indicator of future downtime.

Ultimately, recognizing that pusher plates fight a three-front war against heat, force, and chemistry is the key to engineering a more robust and reliable high-temperature process.

Summary Table:

| Stress Factor | Pusher Plates (Dynamic) | Furnace Lining (Static) |

|---|---|---|

| Thermal Shock | Extreme (rapid heating/cooling cycles) | Minimal (stable temperature) |

| Mechanical Wear | High (abrasion, friction, impact) | None |

| Chemical Attack | Accelerated (cracks provide pathways) | Standard (surface exposure) |

| Primary Failure Mode | Cracking, spalling, accelerated wear | General degradation over time |

Is your pusher furnace performance limited by premature plate failure? KINTEK specializes in high-performance lab equipment and consumables designed to withstand extreme conditions. Our expertise in thermal processing can help you select or develop pusher plates with superior thermal shock resistance and mechanical strength, directly extending your equipment's uptime and reliability. Contact our experts today to discuss a solution tailored to your specific furnace and process requirements.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results