In an induction furnace, high frequency alternating current is used because it is the most efficient method for generating intense, controllable heat directly within the metal itself. This process relies on two key physical principles: electromagnetic induction and the skin effect, which combine to create rapid, clean, and precise heating without any external flame or element.

The core reason for using high frequency is not just to create heat, but to control exactly where and how quickly that heat is generated. This precision is the foundation for all the benefits of induction technology, from material purity to energy efficiency.

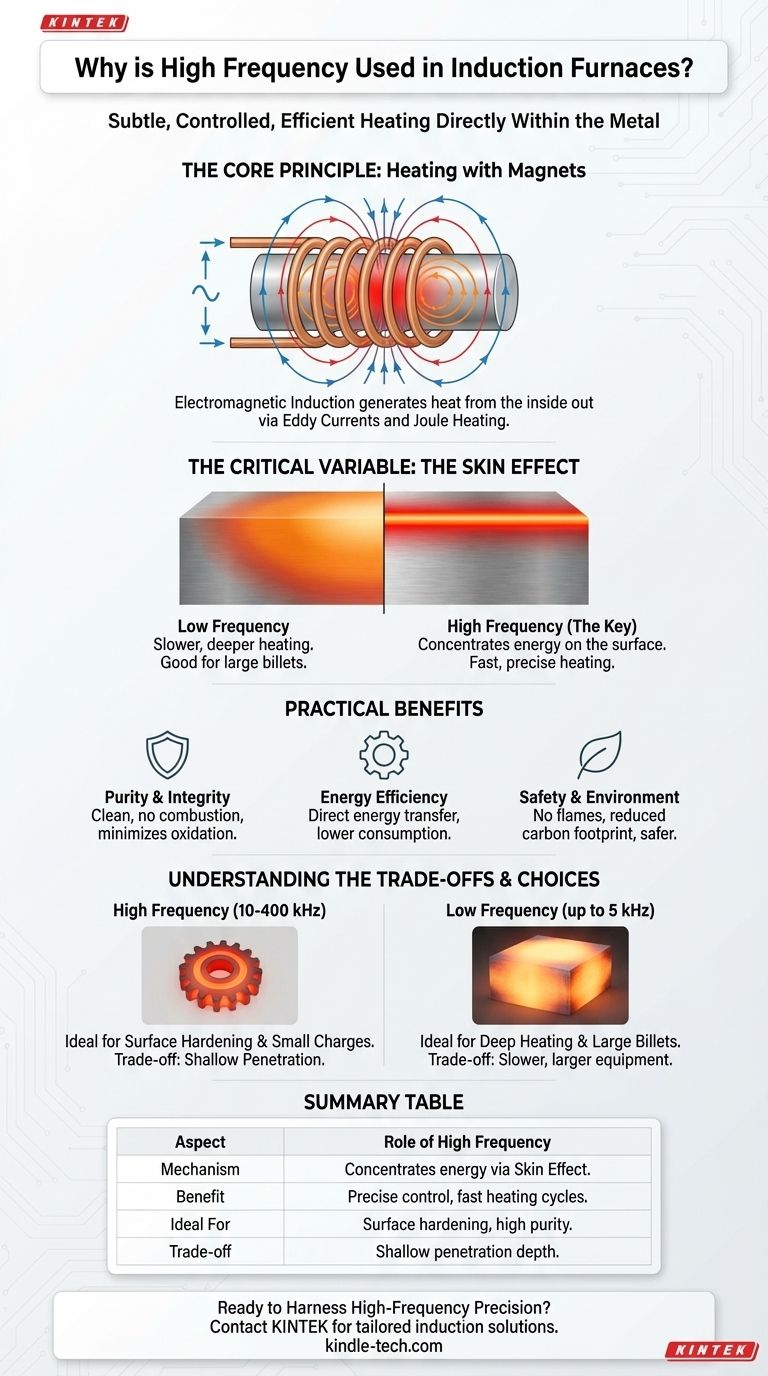

The Core Principle: Heating Metal with Magnets

To understand the role of frequency, we must first understand the basics of induction. The process is a clever application of physics that generates heat from the inside out.

Creating a Magnetic Field

An induction furnace uses a coil of conductive wire, typically copper. A powerful alternating current (AC) is passed through this coil, creating a strong, rapidly changing magnetic field in the space at the center of the coil.

Inducing Eddy Currents

When a piece of electrically conductive metal (the "charge") is placed inside this magnetic field, the field induces circular electrical currents within the metal. These are known as eddy currents.

Generating Heat Through Resistance

The induced eddy currents flow against the metal's natural electrical resistance. This friction generates immense heat, a phenomenon known as Joule heating. The metal itself becomes the source of the heat, which is why the process is so efficient and clean.

Why Frequency is the Critical Variable

The speed and location of the heating are not accidental; they are a direct result of the frequency of the alternating current supplied to the coil.

The Skin Effect: Concentrating the Heat

As the frequency of the AC current increases, the induced eddy currents are forced to flow in a thinner and thinner layer on the surface of the metal. This phenomenon is called the skin effect.

At high frequencies, nearly all the heating energy is concentrated in this thin outer "skin." This allows the surface of the metal to become extremely hot, very quickly.

Faster, More Efficient Heating

By concentrating the energy on the surface, high-frequency induction achieves an incredibly fast heating speed. The core of the material is then heated via conduction from the super-heated surface. This speed is a major driver of the high production efficiency noted in modern forging and melting operations.

Unmatched Process Control

The heat generated is directly proportional to the power supplied by the high-frequency source. This allows for exceptionally high temperature control accuracy. The heat can be turned on, off, or adjusted instantly, preventing overheating and the loss of valuable or volatile alloying elements.

The Practical Benefits of This Approach

The physics of high-frequency heating directly leads to the significant operational advantages that make induction furnaces a superior choice for many applications.

Purity and Material Integrity

Because the heat is generated internally and there is no combustion, the process is perfectly clean. This prevents contamination from fuel or electrodes, and the rapid heating time minimizes oxidation and decarburization, saving material and preserving its intended properties.

Energy Efficiency

Unlike a traditional furnace that must heat a large chamber and the air within it, an induction furnace applies energy directly to the workpiece. This results in significantly lower energy consumption and a much cleaner working environment with minimal waste heat.

Safety and Environmental Impact

Induction furnaces produce no smoke, pollutants, or combustion byproducts, contributing to a safer workplace and a reduced carbon footprint. The elimination of open flames and arcs dramatically improves operational safety.

Understanding the Trade-offs

While powerful, high-frequency induction is not a universal solution. The choice of frequency involves critical trade-offs based on the specific goal.

Depth of Penetration

The primary trade-off of high frequency is its shallow heating depth due to the skin effect. While excellent for surface hardening or melting smaller pieces, it is inefficient for heating the core of very large metal billets. For those applications, a lower frequency is required to allow the magnetic field to penetrate deeper into the material.

Equipment Complexity

High-frequency power supplies are sophisticated electronic devices. They can be more complex and costly to purchase and maintain than the power systems for lower-frequency or traditional combustion furnaces.

Material Suitability

Induction heating is only effective on materials that are electrically conductive. It cannot be used to directly heat insulators like ceramics or certain types of composites.

Making the Right Choice for Your Goal

The optimal frequency is dictated entirely by the application and the material being processed.

- If your primary focus is rapid surface hardening or melting small-volume charges: A high frequency (10 kHz to 400 kHz) is ideal, as it concentrates energy on the surface for maximum speed.

- If your primary focus is melting large quantities of metal or deep-heating large billets for forging: A lower frequency (line frequency up to 5 kHz) is necessary to ensure the magnetic energy penetrates deep into the material's core.

- If your primary focus is absolute material purity and precise temperature control: The induction method itself is the key advantage, with the specific frequency selected based on the size and shape of your material.

Ultimately, controlling the frequency provides direct control over the heat, transforming a fundamental physical principle into a precise and powerful industrial tool.

Summary Table:

| Aspect | Role of High Frequency |

|---|---|

| Heating Mechanism | Concentrates energy via the skin effect for rapid surface heating. |

| Key Benefit | Enables precise temperature control and fast heating cycles. |

| Ideal For | Surface hardening, melting small charges, and applications requiring high purity. |

| Trade-off | Shallow penetration depth; not ideal for heating large billets throughout. |

Ready to harness the precision of high-frequency induction heating for your lab or production line?

KINTEK specializes in advanced lab equipment, including induction furnaces tailored to your specific material and process requirements. Whether you need rapid surface hardening, clean melting, or precise thermal processing, our solutions deliver unmatched efficiency, purity, and control.

Contact us today to discuss how our induction heating technology can optimize your operations and reduce your energy costs!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting