In engineering and industry, hydraulic pressure is critically important because it provides a simple and exceptionally powerful method for multiplying force. By using an incompressible fluid like oil within a sealed system, a small, easily applied force on a small piston can be converted into an immense output force on a larger piston, enabling tasks that would otherwise require complex and bulky mechanical systems.

The true importance of hydraulic pressure is not just its existence, but its ability to enable force multiplication. This principle allows compact, simple machines to generate and precisely control enormous forces, making it the foundational technology for nearly all modern heavy-duty equipment.

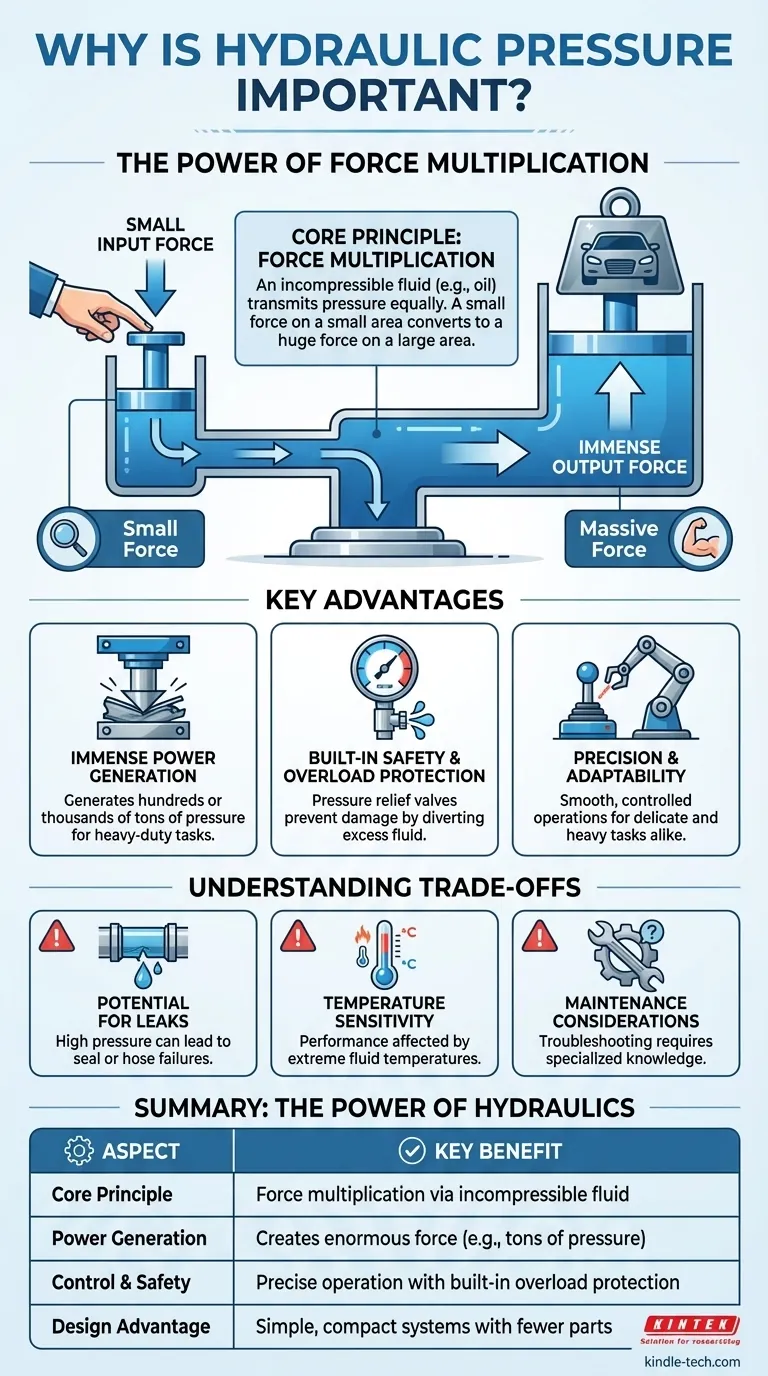

The Core Principle: Force Multiplication

The reason hydraulic systems are so powerful and widely used comes down to a fundamental law of physics applied through clever engineering. It’s about making a small effort do a massive amount of work.

How a Small Input Creates a Massive Output

A hydraulic system works by applying force to a confined, incompressible fluid. Imagine a sealed system with two pistons: a small one for input and a large one for output.

When you apply a small force to the small piston, it creates pressure throughout the fluid. This pressure acts equally on every surface, including the face of the large output piston. Because the large piston has a much greater surface area, that same pressure results in a much larger total force.

The Role of Incompressible Fluids

This effect is only possible because the liquids used in hydraulic systems—typically oil—are incompressible. Unlike air, which can be squeezed, a fluid maintains its volume under pressure.

This means that when you push on the fluid at one end, the pressure is transmitted instantly and evenly to the other end without any energy loss due to compression.

Simplicity in Design

This principle allows for remarkably simple designs. Instead of complex gears, levers, and cams, a hydraulic system primarily consists of a pump, fluid, hoses, and cylinders.

This inherent simplicity, as noted in the references, leads to fewer parts, lower production costs, and a more compact footprint for the amount of power it can deliver.

Key Advantages in Real-World Applications

The principle of force multiplication translates directly into tangible benefits that have shaped modern industry, from manufacturing to construction.

Immense Power Generation

The most obvious advantage is the ability to generate enormous force. Hydraulic presses, for example, use this principle to exert hundreds or thousands of tons of pressure to shape metal or prepare material samples.

This same power is what allows an excavator to lift tons of earth or a car lift to raise a heavy vehicle with ease.

Built-in Safety and Overload Protection

Hydraulic systems have an inherent safety feature: overload protection. The maximum pressure in the system can be set with a simple pressure relief valve.

If the load exceeds this limit, the valve opens and diverts the fluid back to the reservoir, preventing damage to the machine or its tools. This is a significant advantage over mechanical systems, which can break under excessive strain.

Precision and Adaptability

Despite their immense power, hydraulic systems offer exceptional control. By regulating the flow of fluid, an operator can control the speed and force of movement with great precision.

This adaptability allows for smooth, controlled operations, which extends the lifespan of tools and enables delicate tasks even with heavy machinery.

Understanding the Trade-offs

No technology is without its limitations. To have a complete understanding, it's crucial to recognize the potential downsides of relying on hydraulic systems.

Potential for Leaks

Because these systems operate under high pressure, a failed seal or hose can result in a fluid leak. This can be a safety hazard, an environmental concern, and can lead to system downtime for repairs.

Temperature Sensitivity

The performance of a hydraulic system can be affected by temperature. If the fluid gets too hot, its viscosity drops, which can reduce efficiency and increase wear. Conversely, in cold weather, the fluid can become too thick to flow properly.

Maintenance Considerations

While the mechanical design is simple, troubleshooting hydraulic issues requires specialized knowledge. Diagnosing problems related to pressure, flow, or fluid contamination is different from fixing a purely mechanical system.

Making the Right Choice for Your Goal

The decision to use a hydraulic system is based on its unparalleled ability to manage force.

- If your primary focus is generating maximum force: Hydraulics is the ideal solution, as its ability to multiply force is unmatched by mechanical systems of a similar size and cost.

- If your primary focus is precise control over heavy loads: The smooth and highly adaptable operation of a hydraulic system offers superior control for tasks requiring both power and finesse.

- If your primary focus is system safety and longevity: The inherent overload protection and simple, robust design of hydraulic systems reduce wear on tools and prevent catastrophic failure.

Ultimately, understanding hydraulic pressure is key to harnessing one of engineering's most powerful and versatile tools for doing heavy work.

Summary Table:

| Aspect | Key Benefit |

|---|---|

| Core Principle | Force multiplication via incompressible fluid |

| Power Generation | Creates enormous force (e.g., tons of pressure) |

| Control & Safety | Precise operation with built-in overload protection |

| Design Advantage | Simple, compact systems with fewer parts |

Need reliable force for your lab or production line? KINTEK specializes in lab equipment and consumables, serving laboratory needs with robust solutions. Whether you require hydraulic presses for sample preparation or other powerful tools, our expertise ensures you get precise, safe, and efficient performance. Contact us today to discuss how we can enhance your operations with the right equipment!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation