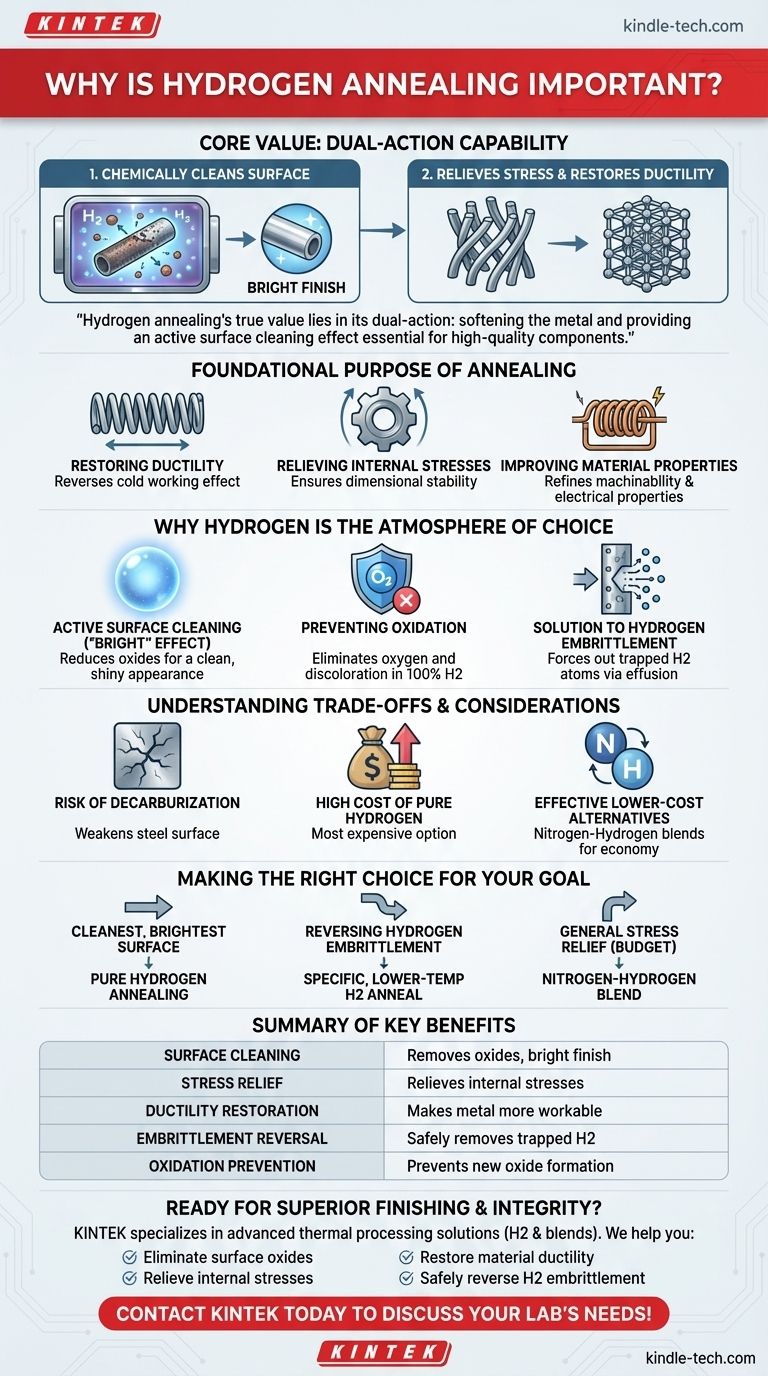

At its core, hydrogen annealing is important because it is a highly effective heat treatment that leverages a pure hydrogen atmosphere to achieve two critical goals: it chemically cleans the metal's surface by removing oxides and prevents any new oxidation from forming. This results in a "bright," clean finish while simultaneously relieving internal stresses and restoring the material's ductility for further processing.

The true value of hydrogen annealing lies in its dual-action capability. It not only softens the metal and makes it more workable—the goal of all annealing—but it also provides an active surface cleaning effect that is essential for high-quality components, especially after processes like welding, coating, or cold working.

The Foundational Purpose of Annealing

Before focusing on the hydrogen element, it's crucial to understand what any annealing process is designed to accomplish. It is a foundational step in metallurgy used to refine a material's properties.

Restoring Ductility

When metal is bent, stretched, or compressed—a process known as cold working—it becomes harder but also more brittle. Annealing reverses this effect, restoring the material's ductility (its ability to be deformed without breaking), which allows for additional processing without the risk of cracking.

Relieving Internal Stresses

Processes like grinding, machining, or welding induce significant mechanical stresses within a material. If left untreated, these stresses can cause the part to distort or warp during subsequent high-temperature treatments or in its final application. Annealing releases these internal stresses, ensuring dimensional stability.

Improving Material Properties

Beyond stress and ductility, annealing can be used to refine other characteristics. It can improve the machinability of a material, making it easier to cut, and in some applications, it is used specifically to enhance a material's electrical properties.

Why Hydrogen Is the Atmosphere of Choice

Using a controlled atmosphere is what elevates standard annealing. Hydrogen is chosen for its unique and powerful chemical properties, which go far beyond simply protecting the material from air.

Active Surface Cleaning (The "Bright" Effect)

Hydrogen is a highly reducing gas. This means it actively reacts with and removes oxides that are already present on the metal's surface. This "surface cleaning" is what produces a clean, scale-free, and shiny appearance, earning the process the name bright annealing.

Preventing Oxidation and Discoloration

Heating metal in the presence of oxygen causes oxidation, leading to discoloration and surface scaling. By performing the heat treatment in a 100% hydrogen atmosphere, oxygen is eliminated, and the formation of new oxides is completely prevented.

A Surprising Solution to Hydrogen Embrittlement

Paradoxically, while trapped hydrogen atoms are the cause of hydrogen embrittlement—a condition where metal becomes brittle—a hydrogen anneal is also the solution. By heating the material to a relatively low temperature (200-300 °C) for several hours, trapped hydrogen is forced out through effusion. This is a critical step immediately after welding or galvanizing, processes known to introduce hydrogen into the material.

Understanding the Trade-offs and Considerations

While powerful, hydrogen annealing is a specialized process with specific challenges that must be managed for successful application.

The Risk of Decarburization in Steel

Hydrogen can react with the carbon in steel parts, a process known as decarburization. This can weaken the surface of the steel, so careful process control and precautions are necessary to avoid damaging the material's integrity.

The High Cost of Pure Hydrogen

An atmosphere of 100% hydrogen is the most expensive option for controlled atmosphere annealing. This cost must be justified by the need for the superior surface finish and cleaning properties that it provides.

Effective Lower-Cost Alternatives

For applications where the absolute brightest finish is not required, nitrogen-hydrogen blends offer an effective and more economical alternative. These blends still provide excellent protection against oxidation and can deliver many of the benefits of pure hydrogen at a lower operational cost.

Making the Right Choice for Your Goal

Selecting the correct annealing process depends entirely on the material's condition and the desired outcome for the final part.

- If your primary focus is achieving the cleanest, brightest possible surface: Pure hydrogen annealing is the superior choice due to its active oxide-reducing properties.

- If your primary focus is reversing hydrogen embrittlement after welding or plating: A specific, lower-temperature hydrogen anneal is the prescribed method for removing trapped hydrogen atoms.

- If your primary focus is general stress relief with a budget constraint: A nitrogen-hydrogen blend often provides sufficient oxidation prevention and is a more cost-effective solution.

Ultimately, choosing the right atmospheric treatment is a critical decision for ensuring both the aesthetic quality and the structural integrity of your final component.

Summary Table:

| Key Benefit | How Hydrogen Annealing Helps |

|---|---|

| Surface Cleaning | Removes existing oxides, creating a bright, scale-free finish. |

| Stress Relief | Relieves internal stresses from welding or cold working. |

| Ductility Restoration | Makes metal more workable for further processing. |

| Hydrogen Embrittlement Reversal | Safely removes trapped hydrogen atoms after welding or plating. |

| Oxidation Prevention | Pure hydrogen atmosphere prevents new oxide formation during heating. |

Ready to achieve superior metal finishing and component integrity?

At KINTEK, we specialize in advanced thermal processing solutions, including hydrogen annealing furnaces and controlled atmosphere systems. Whether you need the bright, oxide-free finish of pure hydrogen annealing or the cost-effective performance of nitrogen-hydrogen blends, our lab equipment is designed to meet the precise demands of your laboratory or production facility.

We help you:

- Eliminate surface oxides and prevent discoloration.

- Relieve internal stresses for dimensional stability.

- Restore material ductility for further processing.

- Safely reverse hydrogen embrittlement in critical components.

Let our experts help you select the right annealing process for your goals. Contact KINTEK today to discuss your lab's needs!

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the function of a controlled atmosphere furnace? Master Nitriding for AISI 52100 & 1010 Steel

- What is the role of nitrogen in annealing process? Creating a Controlled, Protective Atmosphere

- What role does a high-purity argon gas blanket play in high-temperature corrosion testing? Ensure Precise Data Accuracy

- Why is a high-temperature furnace with inert gas protection required for thermal aging of stainless steel?

- Why are controlled atmosphere furnaces required for NCD coating modification? Unlock Superior Biocompatibility.

- What is considered an inert atmosphere? A Guide to Chemical Stability and Process Safety

- What type of gases is used in a heat treat furnace? Control Your Metal's Final Properties

- What is the atmosphere of a furnace? A Guide to Controlling Your Thermal Process