Controlling the experimental environment in electrolysis is absolutely critical for obtaining accurate, reliable, and reproducible results. An unstable environment introduces hidden variables, primarily temperature fluctuations, that directly skew measurements by altering reaction rates, electrolyte properties, and overall system efficiency.

The core reason for environmental control is to eliminate ambiguity. It ensures that the data you collect reflects the intended variables of your experiment—like catalyst material or applied voltage—and not the random thermal changes in your laboratory.

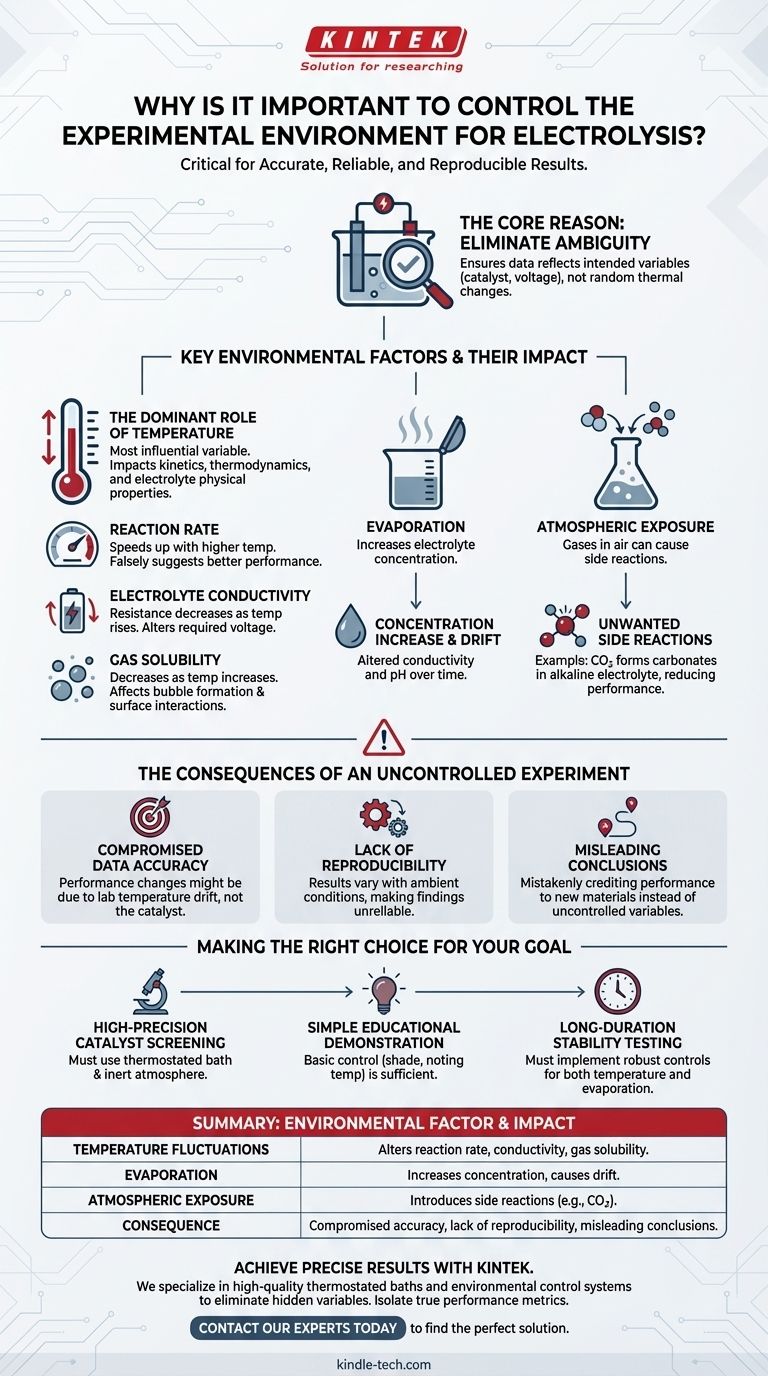

Key Environmental Factors and Their Impact

To understand the importance of control, we must break down the specific factors at play and how they can systematically corrupt your results.

The Dominant Role of Temperature

Temperature is arguably the single most influential environmental variable in an electrochemical system.

Its effects are multifaceted, impacting the kinetics of the reaction (how fast it proceeds), the thermodynamics (the required energy), and the physical properties of the electrolyte. A change of even a few degrees can have a significant, measurable impact.

How Temperature Alters Your System

- Reaction Rate: Most chemical reactions, including electrochemical ones, speed up at higher temperatures. This means you might observe a higher current at the same voltage, falsely suggesting better performance.

- Electrolyte Conductivity: The resistance of the electrolyte typically decreases as temperature rises. This change in conductivity directly alters the overall voltage required to run the cell, confounding your efficiency calculations.

- Gas Solubility: In processes that produce gas, like water splitting, the solubility of those gases (hydrogen and oxygen) in the electrolyte decreases as temperature increases. This can affect bubble formation and electrode surface interactions.

The Effect of Evaporation

Evaporation of the solvent, usually water, is a direct consequence of elevated temperatures or prolonged exposure to open air.

This process steadily increases the concentration of your electrolyte. A more concentrated electrolyte will have different properties, including altered conductivity and pH, introducing a drift in your system's behavior over the course of the experiment.

The Influence of Atmospheric Exposure

For many electrochemical systems, the surrounding atmosphere is not a neutral observer.

Gases in the air can dissolve into the electrolyte and cause unwanted side reactions. A classic example is carbon dioxide (CO2) dissolving in an alkaline electrolyte to form carbonates, which reduces the concentration of active hydroxide ions and diminishes performance.

The Consequences of an Uncontrolled Experiment

Failing to manage these environmental factors doesn't just introduce minor errors; it can fundamentally invalidate your entire experiment.

Compromised Data Accuracy

If the temperature of your cell drifts during a multi-hour test, you are no longer comparing like with like. A performance change you attribute to catalyst degradation might simply be the result of the lab cooling down overnight.

Lack of Reproducibility

Reproducibility is the cornerstone of scientific and engineering validation. If your experiment run on a hot summer day yields different results from the same experiment run in a cold winter lab, your findings are unreliable and cannot be verified by others.

Misleading Conclusions

The most dangerous outcome is drawing the wrong conclusion. Without environmental control, you might mistakenly credit a performance gain to a new material when the true cause was an uncontrolled variable, leading to wasted time and flawed future research.

Making the Right Choice for Your Goal

The necessary level of control depends entirely on your objective.

- If your primary focus is high-precision catalyst screening: You must use a thermostated water bath and potentially an inert atmosphere to isolate the catalyst's true performance.

- If your primary focus is a simple educational demonstration: Basic control, like keeping the cell out of direct sunlight and noting the starting temperature, is sufficient to show the principle.

- If your primary focus is long-duration stability testing: You must implement robust controls for both temperature and evaporation, as small drifts will compound over hours or days, invalidating the test.

Ultimately, rigorous environmental control is what transforms an ambiguous observation into a defensible and valuable result.

Summary Table:

| Environmental Factor | Primary Impact on Electrolysis |

|---|---|

| Temperature Fluctuations | Alters reaction rate, electrolyte conductivity, and gas solubility. |

| Evaporation | Increases electrolyte concentration, causing drift in system behavior. |

| Atmospheric Exposure | Introduces side reactions (e.g., CO2 forming carbonates in alkaline solutions). |

| Consequence | Compromised data accuracy, lack of reproducibility, and misleading conclusions. |

Achieve Precise and Reproducible Electrolysis Results with KINTEK

Struggling with inconsistent data from your electrochemical experiments? The key to reliable results lies in controlling your experimental environment. KINTEK specializes in high-quality lab equipment, including thermostated baths and environmental control systems, designed to eliminate hidden variables like temperature fluctuations and evaporation.

We understand the critical needs of researchers and lab technicians focused on catalyst screening, material testing, and long-duration stability studies. Our solutions help you isolate true performance metrics, ensuring your findings are accurate, defensible, and reproducible.

Stop guessing and start validating. Contact our experts today to find the perfect environmental control solution for your electrolysis setup.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Button Battery Case for Battery Lab Applications

People Also Ask

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide