Preventing mechanical damage to a carbon fiber brush is critical because it directly compromises the two properties that make it effective: electrical conductivity and surface area. When the delicate carbon fibers are broken through bending or impact, they can no longer efficiently transfer electrons or provide attachment sites, which severely degrades the performance of the entire system it's a part of.

The core issue is that a carbon fiber brush operates as a massive, interconnected network. Damaging even a fraction of the fibers isolates parts of that network, reducing the brush's ability to perform its fundamental electrochemical and physical functions.

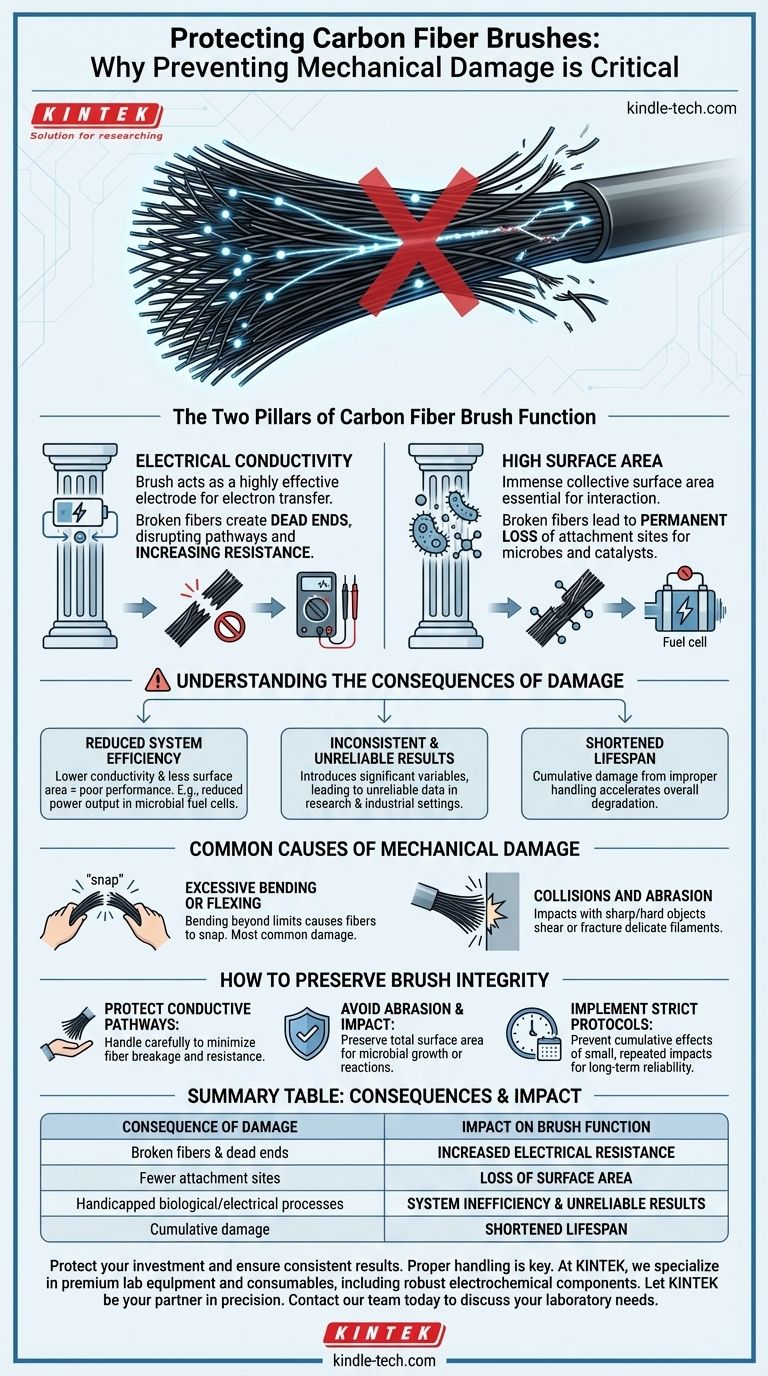

The Two Pillars of Carbon Fiber Brush Function

A carbon fiber brush's value comes from two distinct but related properties. Mechanical damage undermines both simultaneously, leading to a rapid decline in performance.

Pillar 1: Electrical Conductivity

The brush is designed to act as a highly effective electrode, collecting and transferring electrons throughout its structure.

Broken fibers disrupt this crucial function by creating dead ends in the electrical pathway. This effectively increases the overall resistance of the brush, making it a less efficient conductor.

Pillar 2: High Surface Area

The immense collective surface area provided by thousands of individual microfibers is essential for applications requiring interaction with the surrounding medium.

In bioreactors or microbial fuel cells, this surface is where microbes attach and thrive. When fibers break, the available surface area for these vital processes is permanently lost.

Understanding the Consequences of Damage

The degradation caused by broken fibers is not theoretical; it has direct, negative impacts on the systems where these brushes are used.

Reduced System Efficiency

In any electrochemical system, reduced conductivity and lower surface area lead to poor performance.

For example, in a microbial fuel cell, this translates directly to lower power output and less effective wastewater treatment because the biological and electrical processes are handicapped.

Inconsistent and Unreliable Results

A damaged brush introduces a significant variable into any process.

This can lead to inconsistent performance and unreliable data, which is especially problematic in research settings or industrial applications where repeatability is essential.

Common Causes of Mechanical Damage

Understanding what constitutes "damage" is the first step toward preventing it. These brushes are robust in their intended application but can be fragile when handled improperly.

Excessive Bending or Flexing

While designed for some flexibility, bending the fibers beyond their limit will cause them to snap. This is one of the most common forms of handling-related damage.

Collisions and Abrasion

Allowing the brush to collide with sharp or hard objects can easily shear or fracture the delicate carbon filaments. This includes dropping the brush or scraping it against the walls of a container.

How to Preserve Brush Integrity

Proper handling is not just a suggestion; it is a requirement for achieving the performance the brush was designed for.

- If your primary focus is electrochemical performance: Handle the brush carefully to protect its conductive pathways, as every broken fiber contributes to higher electrical resistance.

- If your primary focus is biological attachment or catalysis: Avoid any abrasion or impact that could reduce the total available surface area for microbial growth or chemical reactions.

- If your primary focus is long-term reliability: Implement strict handling protocols to prevent the cumulative effect of small, repeated impacts and flexes over time.

Ultimately, treating the carbon fiber brush with care ensures it can function as the high-performance component it was designed to be.

Summary Table:

| Consequence of Damage | Impact on Brush Function |

|---|---|

| Reduced Electrical Conductivity | Broken fibers create dead ends, increasing resistance and hindering electron transfer. |

| Loss of Surface Area | Fewer attachment sites for microbes or catalysts, reducing system performance. |

| System Inefficiency | Leads to lower power output (e.g., in fuel cells) and unreliable results. |

| Shortened Lifespan | Cumulative damage from improper handling accelerates degradation. |

Protect your investment and ensure consistent results. Proper handling is key to maintaining the high performance of your carbon fiber brushes. At KINTEK, we specialize in premium lab equipment and consumables, including robust electrochemical components designed for reliability. Our experts can help you select the right tools and establish best practices for your specific application—whether it's a bioreactor, fuel cell, or research project.

Let KINTEK be your partner in precision. Contact our team today to discuss your laboratory needs and discover how our solutions can enhance your efficiency and data integrity.

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

People Also Ask

- What are 3 benefits of biomass energy? Turn Waste into Renewable Power

- How should a carbon fiber brush be stored after cleaning? Preserve Performance and Longevity

- What are the 3 types of biomass? A Guide to Woody, Agricultural, and Waste Sources

- What are 3 types of biomass? A Guide to Wood, Waste, and Biofuels for Energy

- What does the regular maintenance inspection of a carbon fiber brush entail? Ensure Peak Performance and Longevity