In material science and industrial processing, sieve analysis is critically important because it measures the particle size distribution of a granular material. This single characteristic directly dictates a product's physical behavior, chemical reactivity, and overall quality, making its measurement a cornerstone of process control and quality assurance in industries from construction to pharmaceuticals.

The core issue for any producer of granular materials is ensuring consistency and performance. Sieve analysis is the most established, cost-effective, and reliable method to verify that a material’s particle size meets the exact specifications required for its intended application, preventing costly failures in production and in the final product.

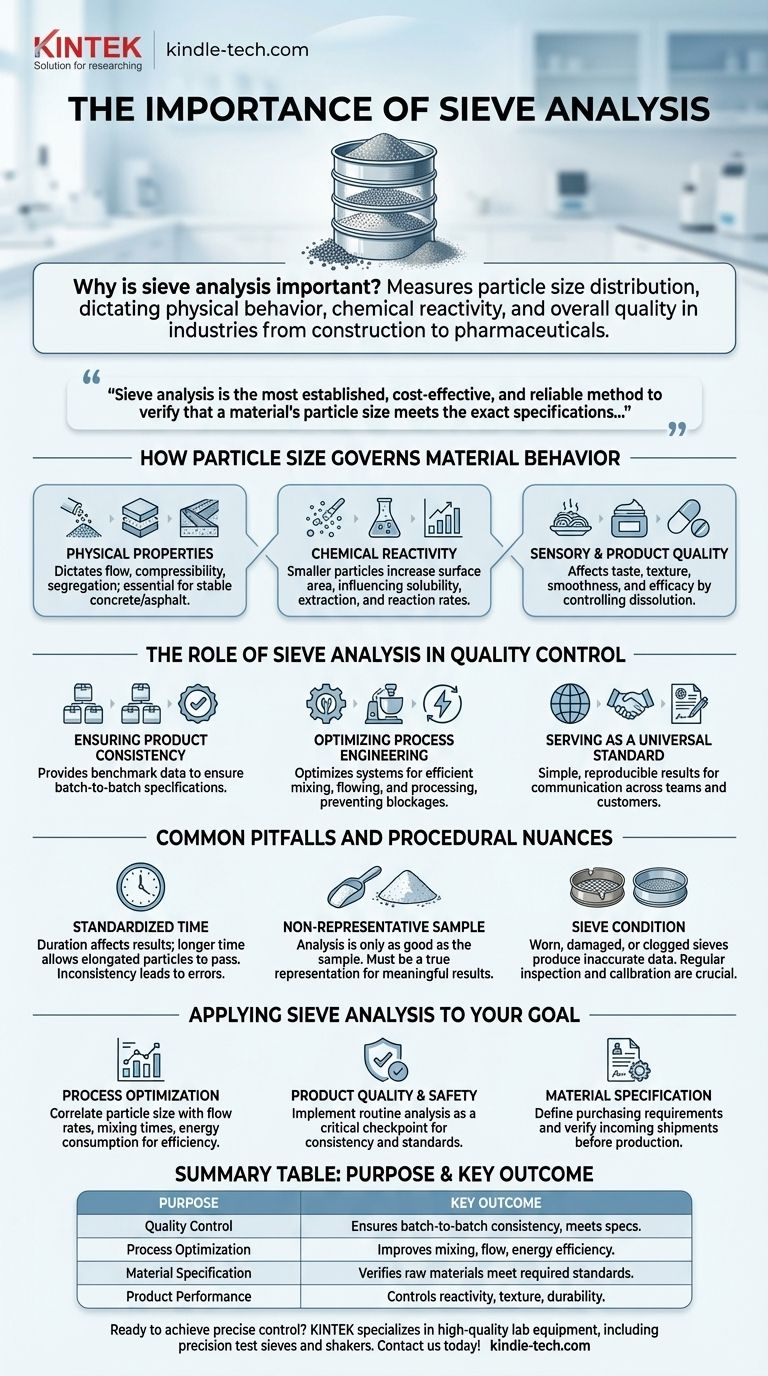

How Particle Size Governs Material Behavior

The distribution of particle sizes within a batch of material is not an abstract metric; it has direct, measurable consequences on how that material behaves in the real world.

The Impact on Physical Properties

A material's particle size dictates its bulk properties. This includes its flow and conveying behavior, its compressibility, and its tendency to segregate. In civil engineering, this is essential for creating stable and durable concrete and asphalt mixes.

The Influence on Chemical Reactivity

Chemical processes are often surface-area dependent. Smaller particles have a much higher collective surface area than larger particles of the same mass, which directly influences properties like solubility, extraction efficiency, and reaction rates.

The Effect on Sensory and Final Product Quality

For many consumer products, particle size is a key component of quality. It affects the taste and texture of food products, the smoothness of cosmetics, and the efficacy of pharmaceuticals by controlling dissolution rates.

The Role of Sieve Analysis in Quality Control

Because particle size is so fundamental, measuring it becomes a primary goal of any robust quality control program. Sieve analysis has remained the industry standard for this task for centuries.

Ensuring Product Consistency

Sieve analysis provides a fast and accurate snapshot of particle size distribution. Manufacturers use this data as a benchmark to ensure that every batch, from the first to the last, meets the same specifications, which is essential for brand reputation and product safety.

Optimizing Process Engineering

By understanding the particle size of raw and in-process materials, engineers can optimize their systems. This ensures efficient mixing, flowing, and processing, preventing blockages and reducing energy consumption.

Serving as a Universal Standard

The results from a sieve analysis are simple, reproducible, and easily understood. This makes it an invaluable communication tool between production teams, quality control labs, sales departments, and even the end customer, ensuring everyone is aligned on material specifications.

Common Pitfalls and Procedural Nuances

While the method is straightforward, its accuracy depends on proper procedure. Overlooking key details can lead to misleading results.

The Importance of Standardized Time

The duration of sieving is a critical variable. A longer interval increases the chance that near-size or elongated particles will correctly orient themselves to pass through the mesh. An inconsistent sieving time will produce inconsistent results.

The Risk of a Non-Representative Sample

The analysis is only as good as the sample it measures. If the small sample drawn for testing is not a true representation of the entire batch, the results will not be meaningful for overall quality control.

The Condition of the Sieves

Test sieves are precision instruments that can wear out or become damaged. Using sieves with stretched, warped, or clogged mesh will produce inaccurate data and must be avoided through regular inspection and calibration.

Applying Sieve Analysis to Your Goal

To leverage sieve analysis effectively, you must align the test with your specific objective.

- If your primary focus is process optimization: Use sieve data to correlate particle size distribution with metrics like flow rates, mixing times, and energy consumption to find the most efficient operational parameters.

- If your primary focus is product quality and safety: Implement routine sieve analysis as a critical quality control checkpoint to guarantee batch-to-batch consistency and meet regulatory or customer standards.

- If your primary focus is material specification: Rely on sieve analysis to define purchasing requirements for raw materials and to verify that incoming shipments meet those precise specifications before they enter your production line.

Ultimately, mastering sieve analysis provides direct and reliable control over the fundamental properties that define your material's performance and success.

Summary Table:

| Purpose of Sieve Analysis | Key Outcome |

|---|---|

| Quality Control | Ensures batch-to-batch consistency and meets product specifications. |

| Process Optimization | Improves mixing, flow, and energy efficiency in production. |

| Material Specification | Verifies raw materials meet required standards before use. |

| Product Performance | Controls properties like reactivity, texture, and durability. |

Ready to achieve precise control over your material's quality and performance? KINTEK specializes in high-quality lab equipment, including precision test sieves and sieve shakers, designed to deliver accurate and reliable particle size analysis for your laboratory needs. Ensure your materials meet the highest standards – contact us today to find the perfect solution for your application!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process