Pyrolysis is considered a sustainable technology because it chemically converts low-value waste streams, such as non-recyclable plastics and agricultural biomass, into valuable resources like fuel, chemicals, and carbon-rich solids. It serves as a key pillar in the circular economy by diverting waste from landfills, reducing greenhouse gas emissions compared to alternatives like incineration, and creating renewable energy and materials. However, its true sustainability is not automatic and depends heavily on the feedstock used, process efficiency, and the final application of its products.

The core principle making pyrolysis a sustainable option is its ability to act as a bridge technology. It closes the loop between waste disposal and resource creation, transforming an environmental liability into a valuable asset within a circular economic model.

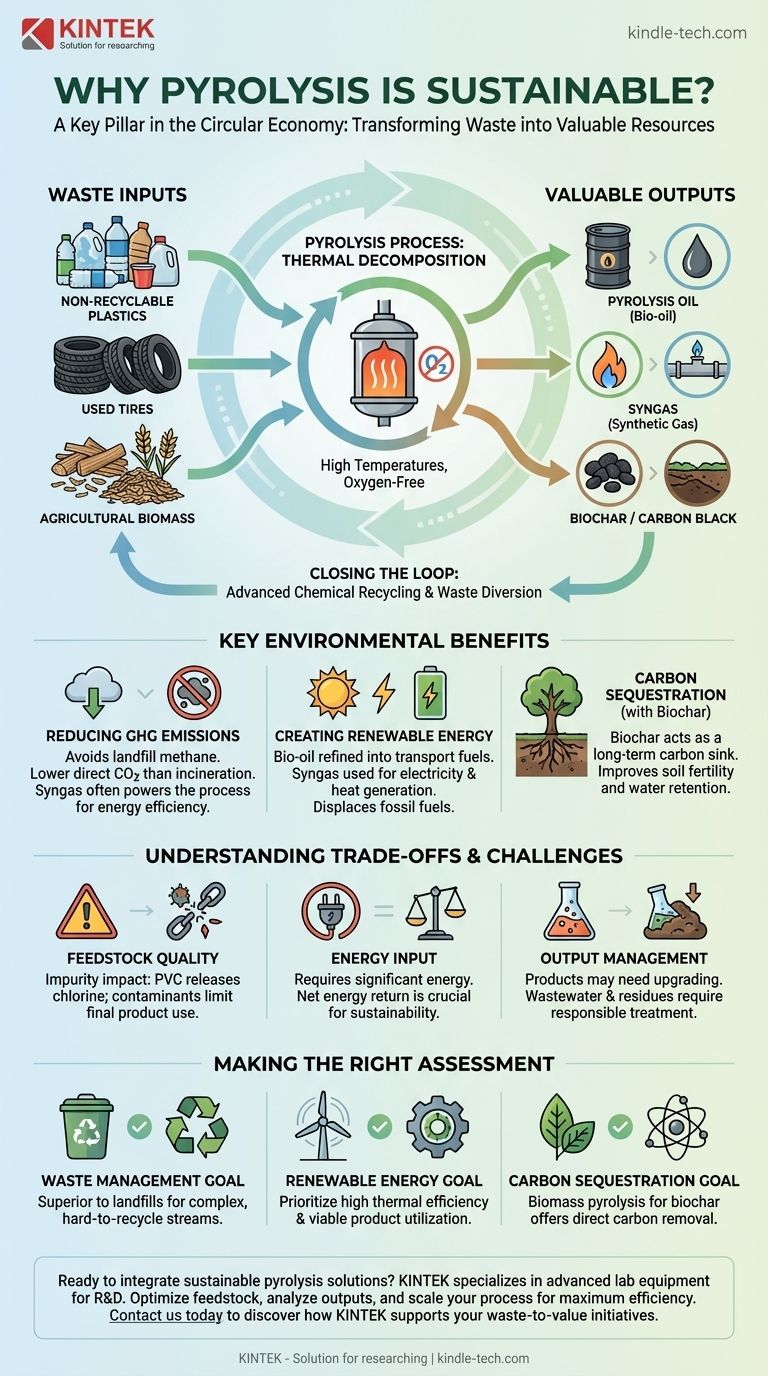

How Pyrolysis Drives a Circular Economy

Pyrolysis is a process of thermal decomposition, breaking down materials at high temperatures in an oxygen-free environment. Unlike burning (incineration), this process doesn't combust the material but instead chemically transforms it into new, valuable substances.

Transforming Waste into Value

The primary function of pyrolysis is to unlock the value stored in waste. It takes materials that have reached the end of their life and deconstructs them into fundamental components.

- Feedstocks: Common materials include end-of-life plastics, used tires, and organic biomass like wood chips or crop residues.

- Outputs: The process yields three main products: pyrolysis oil (or bio-oil), a synthetic gas called syngas, and a solid carbon residue known as biochar (from biomass) or carbon black (from tires/plastics).

Enabling Advanced Chemical Recycling

For plastics, pyrolysis represents a form of advanced or chemical recycling. It can handle mixed and contaminated plastic streams that are unsuitable for traditional mechanical recycling.

The process breaks polymers down into their basic hydrocarbon building blocks. These can then be used as a feedstock to create new, virgin-quality plastics, effectively closing the loop on plastic production.

Diverting Waste from Landfills

Landfills are a significant source of environmental pollution. They release methane, a potent greenhouse gas, and can lead to soil and groundwater contamination.

By processing waste that would otherwise be landfilled, pyrolysis directly mitigates these environmental risks. This is especially critical for materials like plastics and tires that do not readily biodegrade.

Key Environmental Benefits

When implemented correctly, a pyrolysis system offers distinct advantages over conventional waste management and energy production methods.

Reducing Greenhouse Gas Emissions

Compared to the alternatives, pyrolysis often presents a better carbon footprint. It avoids the methane emissions from landfills and can have lower direct CO2 emissions than incineration.

Furthermore, the syngas produced is typically used to power the pyrolysis process itself, reducing the need for external fossil fuel inputs and improving the system's net energy balance.

Creating Renewable Energy Sources

The outputs of pyrolysis are effective energy carriers. Pyrolysis oil can be refined into transportation fuels like diesel or used in boilers and furnaces, displacing conventional fossil fuels. Syngas can be combusted in engines or turbines to generate electricity and heat.

Producing Carbon-Sequestering Biochar

When biomass is the feedstock, the solid byproduct is biochar. This is a highly stable form of carbon that resists decomposition for hundreds or thousands of years.

When this biochar is added to agricultural soil, it acts as a powerful carbon sink, actively removing CO2 from the atmosphere. It also improves soil fertility and water retention, creating a co-benefit for agriculture.

Understanding the Trade-offs and Challenges

The sustainability of pyrolysis is not guaranteed. It is a complex industrial process with critical dependencies and potential downsides that must be managed.

Feedstock Quality is Crucial

The composition of the waste feedstock has a massive impact on the process. Contaminants like PVC plastic can release chlorine, creating corrosive acids that damage equipment and produce hazardous byproducts. Heavy metals or other impurities can end up in the final products, limiting their use.

Energy Input Requirements

Pyrolysis requires a significant amount of energy to reach and maintain its high operating temperatures. A system's sustainability hinges on its net energy return. If it consumes more energy from external fossil fuels than it produces, its environmental benefit is severely compromised.

Management of Outputs and Residues

The products of pyrolysis are not always ready for immediate use. Pyrolysis oil, for example, is often acidic and unstable, requiring significant and costly upgrading before it can be used as a refinery-ready feedstock. Wastewater and residual solids must also be treated and disposed of responsibly.

Making the Right Assessment for Your Goal

Evaluating the sustainability of a pyrolysis project requires looking beyond the core technology to its specific application, energy balance, and integration within the local economy.

- If your primary focus is waste management: Pyrolysis offers a superior alternative to landfills for specific, hard-to-recycle waste streams like mixed plastics, tires, or contaminated biomass.

- If your primary focus is renewable energy production: Prioritize systems with high thermal efficiency and a clear, economically viable plan for upgrading and utilizing the resulting pyrolysis oil and syngas.

- If your primary focus is carbon sequestration: Biomass pyrolysis that produces biochar for soil application provides one of the most direct and verifiable paths to long-term carbon removal and storage.

Ultimately, a truly sustainable pyrolysis operation is one that is carefully engineered as an integrated system, optimizing for feedstock purity, energy efficiency, and the highest-value use of all its products.

Summary Table:

| Aspect | Key Factor | Impact on Sustainability |

|---|---|---|

| Feedstock | Non-recyclable plastics, biomass | Diverts waste from landfills, enables circular economy |

| Process | Thermal decomposition without oxygen | Prevents harmful emissions from burning |

| Outputs | Pyrolysis oil, syngas, biochar | Creates renewable energy and carbon-sequestering materials |

| Efficiency | Net energy balance and product quality | Determines overall environmental benefit |

Ready to integrate sustainable pyrolysis solutions into your operations? KINTEK specializes in advanced lab equipment and consumables tailored for pyrolysis research and development. Whether you're optimizing feedstock, analyzing outputs, or scaling your process, our precision tools help you maximize efficiency and sustainability. Contact us today to discover how KINTEK can support your waste-to-value initiatives with reliable, high-performance laboratory solutions.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What is the physical description of a tube furnace? A Detailed Breakdown of its High-Temperature Design

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning