The short answer is no. While a press using a gas would technically function based on the same physical principles, it would not operate "properly" or safely. Replacing the incompressible liquid with a highly compressible gas fundamentally changes the system's behavior, making it inefficient, uncontrollable, and dangerously explosive.

The core issue is compressibility. Hydraulic systems are powerful because liquids are incompressible, instantly transmitting force. Pneumatic (gas) systems waste energy compressing the gas before any work is done, creating a spongy, imprecise, and hazardous store of energy.

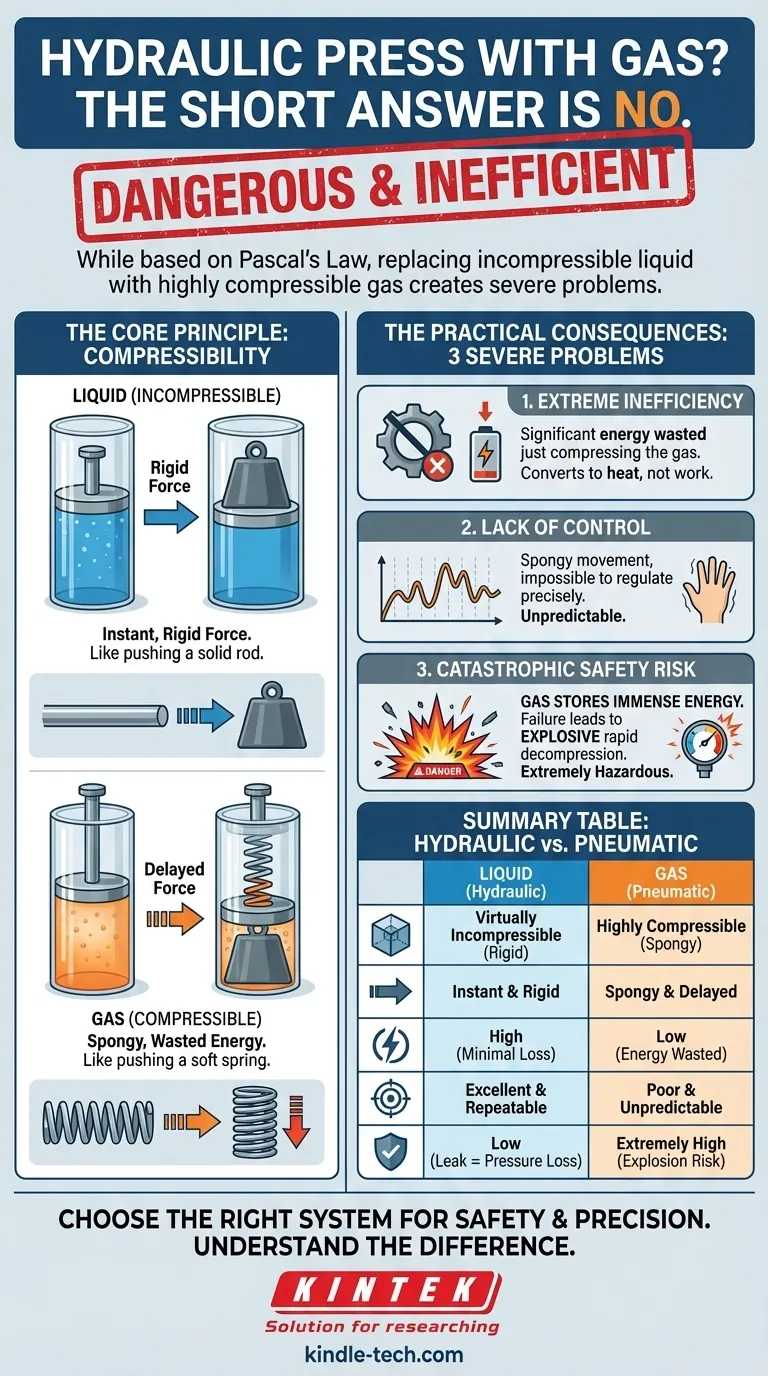

The Core Principle: Pascal's Law and Compressibility

At first glance, both liquids and gases seem suitable for a press. Both are fluids that can transmit pressure, but their response to that pressure is dramatically different.

How a Press Multiplies Force

A press, whether hydraulic or pneumatic, operates on Pascal's Law. This principle states that pressure applied to a confined fluid is transmitted equally throughout the entire fluid.

By applying a small force to a small piston, you create pressure. This pressure then acts on a much larger piston, generating a proportionally larger output force. This principle works for both gases and liquids.

The Critical Difference: Liquids are Incompressible

The key to a hydraulic press is that the working fluid (typically oil) is virtually incompressible. When you apply force, the liquid's volume does not decrease.

Think of it like pushing a solid steel rod. The force you apply to one end is instantly and completely transferred to the other. This allows for immediate, rigid, and precise transfer of immense force.

The Problem with Gases: They are Highly Compressible

Gases, unlike liquids, are highly compressible. When you apply force to a confined gas, its volume will decrease significantly as the pressure builds.

This is like trying to push something with a soft spring. Much of your initial effort is wasted just squeezing the spring before it's compressed enough to push the object. This "spongy" effect is the primary reason gas is unsuitable for high-force press applications.

The Practical Consequences of Using a Gas

Substituting a gas for a liquid in a press designed for hydraulics introduces three severe problems: inefficiency, lack of control, and a massive safety hazard.

Extreme Inefficiency

In a gas-powered press, a significant portion of the input energy is wasted simply compressing the gas. This energy is converted into heat and does not contribute to the work of moving the press ram. A hydraulic system, by contrast, converts nearly all input energy directly into output force.

Lack of Control and Precision

The compressibility of gas makes the press ram's movement "spongy" and difficult to regulate. As the press meets resistance, the gas will compress further instead of applying a steady force. This makes it impossible to achieve the smooth, precise, and repeatable control that hydraulic presses are valued for.

The Catastrophic Safety Risk: Stored Energy

This is the most critical reason not to use gas. A compressed gas stores a tremendous amount of potential energy. A hydraulic system under pressure contains very little stored energy because the liquid has not been compressed.

If a seal, hose, or cylinder were to fail in a high-pressure gas system, the gas would expand explosively in a phenomenon called rapid decompression. This would release all the stored energy at once, turning failed components into shrapnel. A leak in a hydraulic system simply results in a puddle of oil and a loss of pressure.

Making the Right Choice for the Application

The choice between liquid (hydraulics) and gas (pneumatics) is not about which is better, but which is right for the job.

- If your primary focus is immense force and precise control: You must use a liquid (hydraulics), as its incompressibility guarantees efficient, stable, and predictable power transmission.

- If your primary focus is high-speed, repetitive tasks with lower force requirements: A gas (pneumatics) is often the better, simpler, and faster solution, as seen in tools like nail guns or factory automation.

- If your primary focus is safety in a high-pressure system: Never substitute a gas into a system designed for a liquid, as the risk of explosive failure is exceptionally high.

Understanding the fundamental difference between an incompressible liquid and a compressible gas is the key to engineering a system that is both effective and safe.

Summary Table:

| Aspect | Liquid (Hydraulic) | Gas (Pneumatic) |

|---|---|---|

| Compressibility | Virtually Incompressible | Highly Compressible |

| Force Transmission | Instant & Rigid | Spongy & Delayed |

| Efficiency | High (Minimal Energy Loss) | Low (Energy Wasted Compressing) |

| Control & Precision | Excellent & Repeatable | Poor & Unpredictable |

| Safety Risk | Low (Leak = Loss of Pressure) | Extremely High (Risk of Explosion) |

Ensure your lab's safety and precision with the right equipment from KINTEK.

Choosing the correct system for your application is critical. KINTEK specializes in providing reliable laboratory equipment and consumables tailored to your specific needs. Whether you require the immense force of a hydraulic press or the speed of a pneumatic system, our experts can help you select the safest and most efficient solution for your workflow.

Don't compromise on safety or performance. Contact our team today to discuss your requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How do I choose a press? A Guide to Matching Your Specific Operational Needs

- What technical value does a four-column hydraulic press provide? Optimize Your Composite Powder Fabrication Today

- What are the factors that affect pellet quality? Master KBr Pellet Prep for Flawless FTIR Results

- What are the safety precautions for KBr? Achieve Flawless FTIR Pellet Preparation and Data Accuracy

- What is the purpose of using mechanical pressure in DSSC assembly? Optimize Photoanode and Counter Electrode Stability

- How do I choose a hydraulic press? Match Tonnage, Size & Features to Your Needs

- How do you do the KBr pellet method? A Step-by-Step Guide to Perfect FTIR Sample Preparation

- How do you make a pellet sample? A 4-Step Guide to Perfect Pressed Pellets for Accurate Analysis