You’ve invested in a state-of-the-art induction furnace. It was supposed to be the key to faster, cleaner, more consistent melts. Instead, it’s become a source of constant frustration.

One batch comes out perfectly. The next is contaminated. Your energy bills are higher than you projected, and your team is spending more time troubleshooting the furnace than running production. You’re stuck in a cycle of blaming the raw materials, the operators, or the power grid, but nothing seems to permanently solve the problem.

If this scenario feels uncomfortably familiar, you are not alone. And the root of the problem is likely something you haven't considered: you may be using fundamentally the wrong tool for the job.

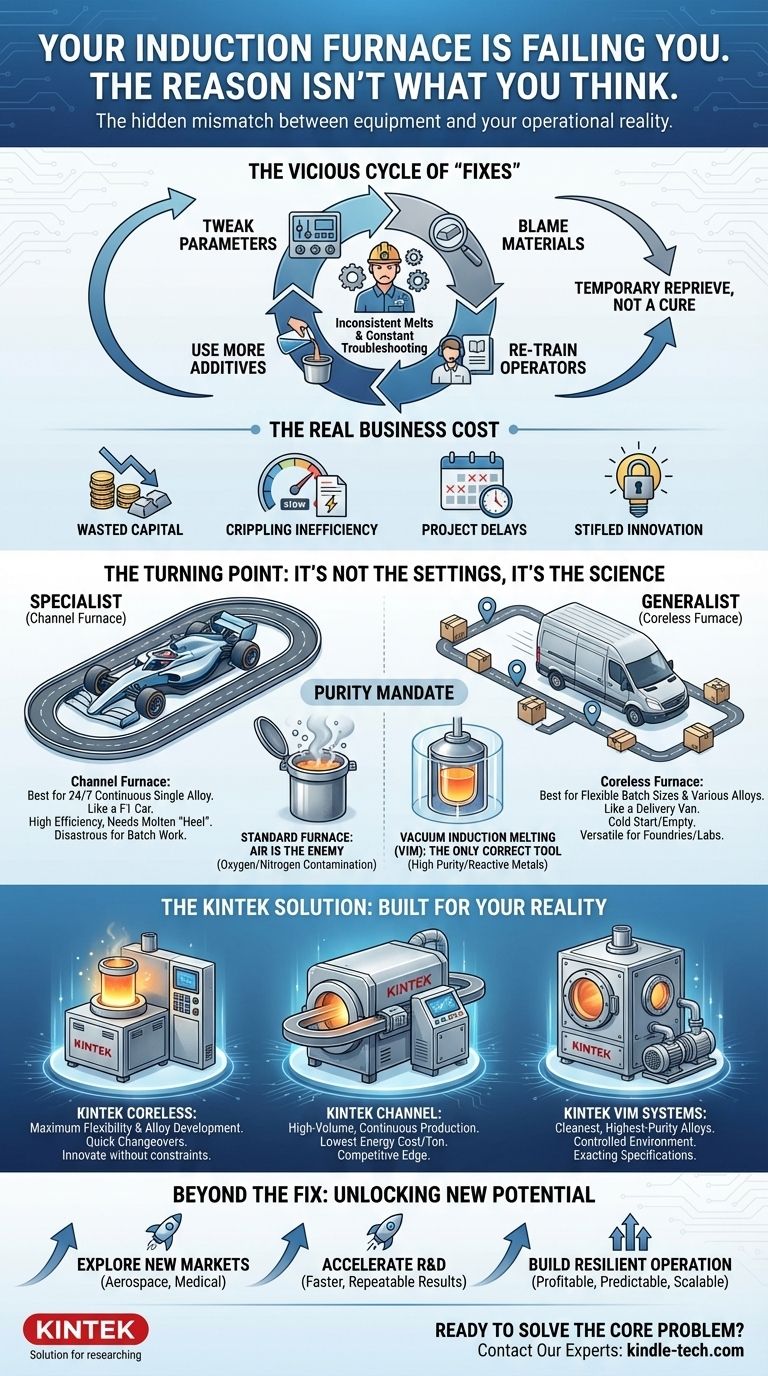

The Vicious Cycle of "Fixes" That Never Work

When facing inconsistent melting results, labs and foundries typically fall into a predictable pattern of troubleshooting. They might:

- Tweak the parameters: Adjusting power cycles, hold times, and temperature settings, hoping to find a magic combination.

- Blame the materials: Questioning the quality of the scrap or ingot, leading to costly changes in suppliers.

- Re-train operators: Assuming the issue is human error, leading to frustration and no improvement in results.

- Use more additives: Attempting to correct contamination with more fluxes or deoxidizers, which adds cost and complexity.

While these actions might offer a temporary reprieve, the inconsistency always returns. That's because these are attempts to treat the symptoms, not the underlying disease.

The Real Business Cost of a Mismatched Tool

This isn't just a technical headache; it's a significant business liability. A mismatched furnace directly leads to:

- Wasted Capital: Thousands of dollars in high-value alloys can be rendered useless by a single contaminated melt.

- Crippling Inefficiency: Excessive energy consumption from using an inefficient furnace for your process eats directly into your profit margins.

- Project Delays: The inability to produce consistent, high-quality material pushes back production timelines and damages your reputation with clients.

- Stifled Innovation: You can't confidently develop new products or work with sensitive new alloys if you can't trust your most fundamental process.

The problem isn’t that your furnace is "bad." The problem is that its core design may be fundamentally at odds with your operational goals.

The Turning Point: It's Not the Settings, It's the Science

The secret to solving this issue lies in understanding that not all induction furnaces are created equal. The choice between the two primary types—Coreless and Channel—is the single most important decision you can make, as it dictates everything about your process.

The Specialist vs. The Generalist: Channel vs. Coreless Furnaces

Think of it like choosing a vehicle. You wouldn't use a Formula 1 car (a highly efficient specialist) for a multi-stop delivery route. And you wouldn't use a delivery van (a flexible generalist) to win a race.

-

The Channel Furnace is the Specialist: It operates like a transformer, using an iron core to heat a continuous, closed loop of molten metal. It is extremely energy-efficient for melting massive volumes of a single alloy, 24/7. However, it must always maintain a "heel" of molten metal to function. Trying to use it for different alloys or small batches is disastrously inefficient and impractical. If you're doing batch work with a channel furnace, you're fighting its very nature.

-

The Coreless Furnace is the Generalist: It works by placing the metal directly in a crucible and heating it from within using a magnetic field. It can be started from cold and emptied completely. This makes it incredibly flexible for melting various alloys and running different batch sizes. It's the perfect tool for foundries and labs that need versatility. However, for a 24/7, single-alloy operation, it can be less energy-efficient than a channel furnace.

The common "fixes" fail because you cannot tweak a channel furnace to behave like a coreless one, or vice-versa. Their physical principles are different.

The Purity Mandate: When Air Is the Enemy

A similar mismatch occurs when dealing with high-purity or reactive metals like titanium or superalloys. If your final product demands absolute purity, but you're using a standard furnace that melts in the open air, you are fighting a losing battle against oxygen and nitrogen contamination. No amount of flux can solve this. For these applications, a Vacuum Induction Melting (VIM) furnace, which melts material inside a vacuum, is not a luxury—it is the only correct tool.

The Solution Embodied: A Furnace Built for Your Reality

True success comes from aligning your equipment's core design with your operational reality. The solution isn't another "fix"; it's a strategic choice based on a correct diagnosis of the problem.

This is where KINTEK's philosophy begins. We understand that a furnace is not just a piece of hardware; it is the heart of your metallurgical process. Our equipment is not designed to be a one-size-fits-all solution, but a precise answer to a specific operational challenge.

- For maximum flexibility and alloy development, our Coreless Induction Furnaces are designed to be emptied, cleaned, and switched over quickly, empowering your lab to innovate without constraints.

- For high-volume, continuous production where efficiency is paramount, our Channel Induction Furnaces provide the lowest possible energy cost per ton, giving you a critical competitive edge.

- For producing the cleanest, highest-purity aerospace or medical-grade alloys, our Vacuum Induction Melting (VIM) Systems provide the controlled environment necessary to eliminate contamination and achieve exacting specifications.

We don't just sell equipment; we provide the expertise to ensure the tool you choose is a perfect match for the job you need to do.

Beyond the Fix: Unlocking New Potential

When you stop fighting your equipment and start using the right tool, something remarkable happens. The energy you once spent on troubleshooting is channeled back into innovation.

- Explore New Markets: With the right furnace, you can confidently take on projects with challenging new alloys or qualify for high-value contracts in demanding sectors like aerospace and medical.

- Accelerate R&D: Your R&D team can get reliable, repeatable results, drastically shortening the development cycle for new materials and products.

- Build a Resilient Operation: With a predictable, efficient, and reliable melting process, your entire operation becomes more profitable, predictable, and scalable.

Your challenge isn't just about melting metal; it's about building a more resilient, innovative, and profitable operation. The journey starts with choosing the right foundation. If you're ready to stop treating symptoms and finally solve the core problem, our team of experts is here to help you diagnose your needs and design a solution that fits. Let's discuss how the right equipment can solve not just your immediate technical issues, but unlock your team's full potential. Contact Our Experts.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

Related Articles

- Comprehensive Guide to Vacuum Hot Press Furnace Application

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

- Vacuum Laboratory Furnaces in Advanced Materials Research

- How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production

- The Ultimate Guide to Vacuum Pressure Sintering Furnace: Benefits, Applications, and Working Principle