Articles

Solutions for Removing a Stuck Spatter Ball from a Rotary Evaporator

11 months agoGuidelines and techniques for removing a stuck spatter ball from a rotary evaporator, including shaking, knocking, baking, freezing, and smashing.

Learn More

Rotary Evaporator and Its Application in Traditional Chinese Medicine Refinement

11 months agoExplores the use of rotary evaporators in the concentration and refinement of traditional Chinese medicine extracts, detailing equipment selection, operation principles, and safety considerations.

Learn More

Exploring the World of Molecular Gastronomy

11 months agoA deep dive into the innovative culinary techniques of molecular gastronomy, its history, and its impact on modern cuisine.

Learn More

Exploring the Science and Techniques of Molecular Cuisine

11 months agoA deep dive into the world of molecular cuisine, its historical roots, key techniques, and how it's becoming accessible for home cooks.

Learn More

The Rise of Molecular Cuisine: A Culinary Revolution Led by Michelin Chefs

11 months agoExploring the fusion of science and cooking, focusing on Michelin-starred innovations.

Learn More

Optimizing Solvent Removal in Organic Reactions using Rotary Evaporators

11 months agoExplores factors affecting solvent removal time and demonstrates rotary evaporator's potential in organic synthesis.

Learn More

Molecular Gastronomy: Techniques and Innovations

11 months agoA comprehensive analysis of molecular gastronomy, its origins, tools, additives, and techniques.

Learn More

Exploring the World of Molecular Gastronomy

11 months agoAn in-depth look at the science behind molecular gastronomy and its culinary applications.

Learn More

Unveiling the Mystery of Molecular Gastronomy

11 months agoExploring the science behind molecular gastronomy, its origins, techniques, and impact on cuisine.

Learn More

Molecular Gastronomy: The Intersection of Science and Culinary Art

11 months agoExploring the fusion of science and cooking, this article delves into molecular gastronomy and its impact on modern cuisine.

Learn More

Rotary Evaporator Basics: Principles, History, Maintenance, and Selection

11 months agoA comprehensive guide on rotary evaporators, covering principles, history, maintenance, and selection criteria.

Learn More

Crafting a Rotary Evaporator Cocktail with Clarified Grapefruit Juice

11 months agoA detailed guide on making a gin cocktail using a rotary evaporator and clarified grapefruit juice, with methods and recipes.

Learn More

Application of Rotary Evaporator in Molecular Mixology

11 months agoExploring the use of rotary evaporators in molecular mixology for cocktail preparation.

Learn More

Advantages and Applications of Rotary Evaporators

11 months agoExplore the benefits and diverse applications of rotary evaporators in various industries.

Learn More

Exploring the World of Molecular Cuisine

11 months agoDelve into the innovative techniques and surprising flavors of molecular cuisine.

Learn More

The Rise of Rotary Evaporators in Cocktail Bars

11 months agoExploring the use of rotary evaporators in modern cocktail bars, from London to Kansas, and their impact on cocktail creation.

Learn More

Rotary Evaporator Operation and Troubleshooting Guide

11 months agoDetailed guide on rotary evaporator parts, applications, handling, operation, and troubleshooting.

Learn More

Comprehensive Analysis of Molecular Cuisine and the Four Heavenly Kings of Molecular Gastronomy

11 months agoAn in-depth look at the tools, additives, and techniques that define molecular cuisine, focusing on its four core methods.

Learn More

Safety Hazards and Precautions for Laboratory Heating Equipment

11 months agoGuidelines on common heating equipment and safety measures in lab settings.

Learn More

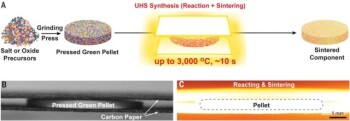

Impact of Sintering Furnaces on Ceramic Manufacturing

11 months agoExplores the role of sintering furnaces in ceramic production, focusing on their applications, heating methods, and effects on ceramic properties.

Learn More

Temperature Control Requirements for Laboratory Small High-Temperature Resistance Furnaces

11 months agoExploring the precision, stability, and safety aspects of temperature control in laboratory small high-temperature resistance furnaces.

Learn More

Precision Ceramics: Types, Working Principles, and Performance Characteristics of Various Sintering Furnaces

11 months agoAn in-depth look at different types of sintering furnaces and their principles, advantages, and disadvantages.

Learn More

In-Depth Understanding of Zirconia Sintering Furnaces

11 months agoAn exploration of zirconia sintering processes, furnace components, and optimal conditions for achieving high-quality dental restorations.

Learn More

The Art and Craft of Making Porcelain Teeth

11 months agoA detailed guide on the intricate process of creating porcelain teeth.

Learn More

Advancements in Muffle Furnace Technology and Applications

11 months agoExplores the principles, types, research, and future prospects of muffle furnaces in various industries.

Learn More

Calibration Methods for High-Temperature Muffle Furnaces

11 months agoExplores traditional and system calibration methods for ensuring temperature accuracy in high-temperature muffle furnaces, focusing on temperature deviation and uniformity.

Learn More

Understanding the Burnout Operation Process of Tube Furnaces

11 months agoExplains the burnout process in tube furnaces, focusing on its principles and applications.

Learn More

Proper Usage and Safety Precautions of Muffle Furnaces

11 months agoGuidelines on using muffle furnaces safely and correctly, including accident cases, equipment details, and operational steps.

Learn More

Comprehensive Guide to Muffle Furnace Resistance Wire Design

11 months agoDetailed analysis of resistance wire design principles, parameters, and calculation techniques for muffle furnace applications.

Learn More

Temperature Control Accuracy of High Temperature Experimental Chamber Muffle Furnace

1 year agoAn in-depth analysis of factors affecting the temperature control accuracy of high temperature muffle furnaces.

Learn More