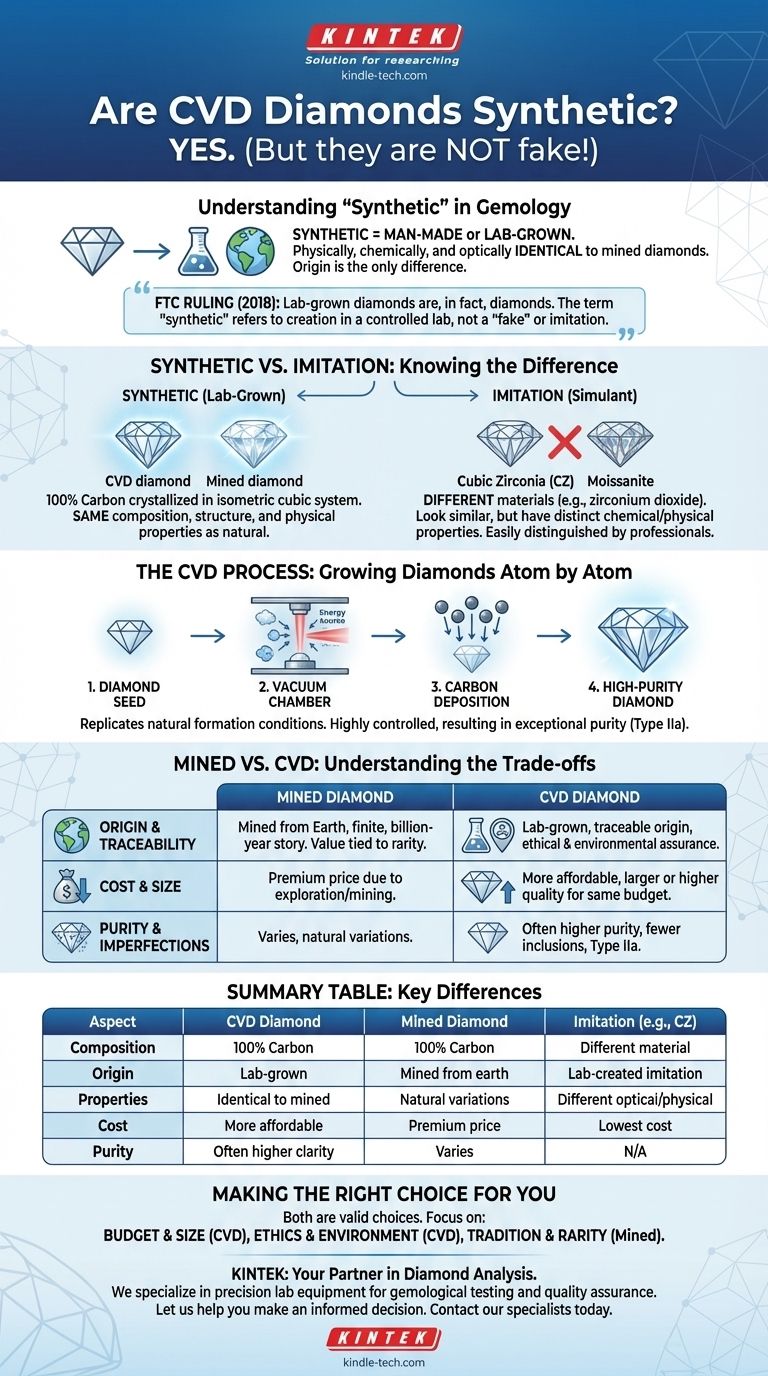

Yes, CVD diamonds are synthetic. However, it is critical to understand that in gemology, "synthetic" simply means man-made or lab-grown. It does not mean they are fake. CVD diamonds are physically, chemically, and optically identical to diamonds mined from the earth; the only difference is their origin.

A CVD (Chemical Vapor Deposition) diamond is a real diamond, not an imitation. The term "synthetic" refers to its creation in a controlled laboratory environment rather than its geological formation. In 2018, the U.S. Federal Trade Commission (FTC) affirmed this by ruling that lab-grown diamonds are, in fact, diamonds.

Why "Synthetic" Doesn't Mean "Fake"

The confusion around CVD diamonds stems from the word "synthetic." In most contexts, we associate it with imitation materials. In the world of gemstones, the term has a very precise, technical meaning that must be understood.

Differentiating Synthetic from Imitation

A synthetic gemstone is a man-made material with the exact same chemical composition, crystal structure, and physical properties as its natural counterpart. A synthetic diamond is 100% carbon crystallized in an isometric cubic system, just like a mined diamond.

An imitation or "simulant" is a different material used to look like a diamond. Common examples include Cubic Zirconia (CZ) or Moissanite. These materials have entirely different chemical and physical properties and can be easily distinguished from a diamond by a professional.

The Official Ruling on a Diamond's Identity

To eliminate consumer confusion, the U.S. Federal Trade Commission (FTC) updated its Jewelry Guides. The agency officially removed the word "natural" from the definition of a diamond.

The FTC's stance is clear: a diamond is a diamond because of its composition, not its origin. A lab-grown diamond is not a "fake" or "imitation" diamond; it is simply a diamond created by humans.

How a Diamond Is Grown in a Lab

The CVD process is a marvel of modern technology that replicates the conditions under which diamonds form in nature, but on a vastly accelerated timeline. It allows for a high degree of control over the final product.

The CVD Process Explained

The process starts with a small, high-quality diamond "seed." This seed is placed inside a vacuum chamber.

The chamber is then filled with a mixture of carbon-rich gases, typically methane and hydrogen, and heated to extreme temperatures.

A microwave beam, laser, or other energy source is used to ignite a plasma, which causes the gas molecules to break apart. This frees carbon atoms, which then rain down and deposit onto the diamond seed, building up new diamond layers, atom by atom.

The Result: A High-Purity Diamond

Because this process occurs under tightly controlled conditions, the resulting diamonds often have exceptional purity and clarity. They can be produced at a fraction of the cost and time of mining, and with fewer impurities than many natural stones.

Even a trained jeweler cannot distinguish a high-quality CVD diamond from a mined one with the naked eye. Advanced gemological equipment is required to identify its lab-grown origin.

Understanding the Trade-offs: Mined vs. CVD

While they are physically the same material, the differences in origin lead to practical considerations for any buyer. The choice between them is not about "real vs. fake," but about which set of priorities matters most to you.

Origin and Traceability

A mined diamond is a finite resource created by immense heat and pressure deep within the earth over billions of years. Its value is tied to its rarity and natural origin.

A CVD diamond has a clear and documented origin from a specific lab. This provides complete traceability, sidestepping the environmental and ethical concerns sometimes associated with diamond mining.

Cost and Size

Without the immense costs of exploration, mining, and a long supply chain, CVD diamonds are significantly more affordable than mined diamonds of comparable size and quality.

This cost difference allows a buyer to purchase a larger or higher-quality diamond for the same budget.

Purity and Imperfections

The controlled environment of a lab allows producers to create diamonds that are often chemically purer and have fewer inclusions (internal flaws) than most mined diamonds. Many CVD diamonds are classified as Type IIa, a category that includes less than 2% of all mined diamonds and is prized for its exceptional brilliance.

Making the Right Choice for Your Goal

Ultimately, both mined and CVD diamonds are valid choices. The "better" option depends entirely on your personal priorities.

- If your primary focus is maximizing size and quality for your budget: A CVD diamond delivers a larger, higher-clarity stone for a significantly lower cost.

- If your primary focus is ethical and environmental assurance: A lab-grown diamond offers a fully traceable and conflict-free origin with a smaller environmental footprint.

- If your primary focus is the tradition and inherent rarity of a geological artifact: A mined diamond's billion-year-old story and finite nature hold a unique and powerful appeal.

Choosing a diamond is about selecting the stone whose story and characteristics align with your values.

Summary Table:

| Aspect | CVD Diamond | Mined Diamond | Imitation (e.g., CZ) |

|---|---|---|---|

| Composition | 100% Carbon (same as natural) | 100% Carbon | Different material (e.g., zirconium dioxide) |

| Origin | Lab-grown | Mined from earth | Lab-created imitation |

| Properties | Identical to mined diamonds | Natural variations | Different optical/physical properties |

| Cost | More affordable | Premium price | Lowest cost |

| Purity | Often higher clarity (Type IIa) | Varies with inclusions | N/A |

Still unsure which diamond is right for your needs?

KINTEK specializes in precision lab equipment and consumables, including technology used in advanced diamond synthesis. Whether you're a jeweler, researcher, or manufacturer, we provide reliable tools for material analysis and quality assurance.

Let us help you make an informed decision:

- Get expert guidance on diamond verification tools

- Explore equipment for gemological testing

- Access consumables for precise lab work

Contact our specialists today to discuss your laboratory needs and ensure the highest standards in your work!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How are microwave plasmas generated? A Guide to High-Precision Ionization for Lab Applications

- What is MP CVD? Unlock the Power of Microwave Plasma for High-Purity Diamond Synthesis

- How does microwave plasma work? Unlock Precision Material Synthesis for Advanced Manufacturing

- How do you test a diamond CVD? Verify Authenticity with Grading Reports & Laser Inscription

- How do you make a lab diamond? Discover the HPHT and CVD Methods Explained

- Are CVD diamonds fake? Discover the Truth About Lab-Grown Diamonds

- Can a diamond be created in a laboratory? The Science Behind Genuine Lab-Grown Diamonds

- What is deposition of diamond films? Grow High-Performance Diamond Coatings with CVD