Yes, a diamond will absolutely break under a hydraulic press. While famous for its extreme hardness, a diamond is also brittle. A hydraulic press applies overwhelming compressive force that far exceeds the diamond's structural strength, causing it to shatter catastrophically.

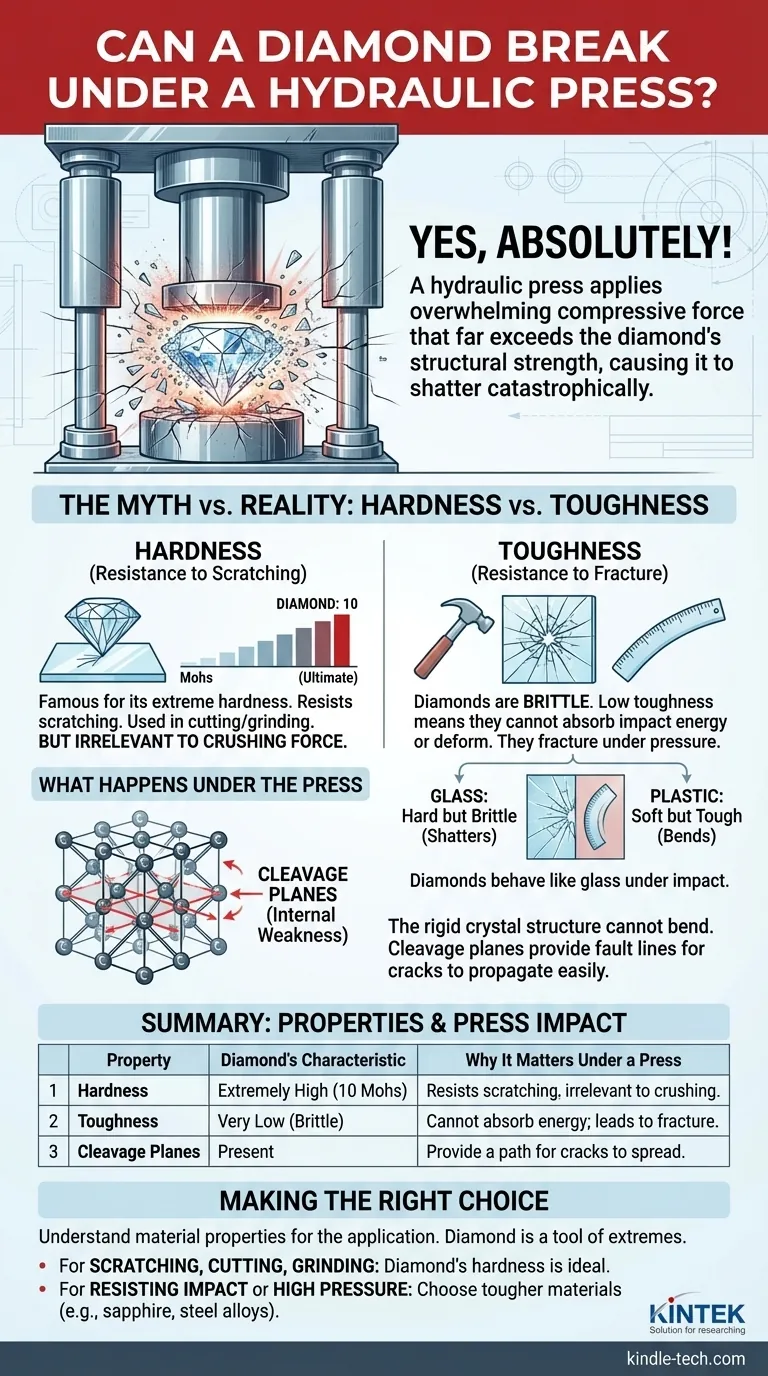

The common belief that diamonds are indestructible comes from confusing two different material properties. The key is understanding that a diamond's exceptional hardness (resistance to scratching) is separate from its relatively low toughness (resistance to fracture).

The Myth of the Unbreakable Diamond

The idea of a diamond's invincibility is rooted in its status as the hardest naturally occurring substance. However, this one exceptional quality overshadows its other, more vulnerable characteristics.

Hardness: The Source of the Misconception

A diamond ranks a 10 on the Mohs scale of mineral hardness. This is a relative scale that measures a material's ability to resist being scratched by another.

Because a diamond can scratch any other mineral, it has earned a reputation for being the ultimate durable material. This property is precisely why it is used in industrial cutting, drilling, and grinding applications.

Toughness: The Overlooked Property

Toughness, or fracture resistance, is a material's ability to absorb energy and resist breaking under impact or pressure. On this front, diamonds are not exceptional.

They are brittle, meaning they fracture or cleave when subjected to sufficient force. This is due to their rigid crystal structure, which does not allow for deformation.

An Intuitive Analogy: Glass vs. Plastic

Think of a pane of glass versus a plastic ruler. The glass is much harder; you can't easily scratch it. The plastic ruler is soft and scratches easily.

However, if you strike both with a hammer, the hard glass shatters (it's brittle), while the soft plastic might dent or bend but remain intact (it's tough). A diamond behaves much more like the glass in this scenario.

What Happens Under the Press

A hydraulic press is designed to deliver a massive amount of force to a small area, creating immense pressure. A diamond's atomic structure is simply not designed to withstand this kind of stress.

Exploiting the Crystal Structure

A diamond consists of carbon atoms arranged in a highly ordered and rigid crystal lattice. While the covalent bonds between these atoms are incredibly strong, they create natural fault lines within the crystal known as cleavage planes.

When a gem cutter wants to shape a diamond, they strategically strike these planes. A hydraulic press applies force indiscriminately, inevitably hitting these weak points and initiating a fracture.

Catastrophic Failure

Under the immense, uniform pressure of the press, the energy has nowhere to go. The diamond's rigid lattice cannot bend or deform to absorb the stress.

Once the pressure exceeds the diamond's compressive strength, the crystal structure fails suddenly and completely. The result is not a dent or a crack but a violent shatter, often reducing the gem to dust and small fragments.

Understanding the Trade-offs: The Diamond's Dilemma

The very properties that make a diamond exceptional in one context make it vulnerable in another. Its strengths are directly linked to its weaknesses.

The Price of a Rigid Structure

The perfectly arranged, tightly bonded atoms that give a diamond its unparalleled hardness also prevent it from absorbing impact energy. Metals can bend and deform because their atomic structures can shift and slip. A diamond's lattice cannot.

Cleavage Planes as Built-in Flaws

While essential for the art of gem cutting, these internal planes of relative weakness are the diamond's Achilles' heel. Under the brute, undirected force of a press, these planes are liabilities that guarantee the diamond's destruction.

Making the Right Choice for Your Goal

Understanding the specific properties of a material is critical for applying it correctly. A diamond is a tool of extremes, not an all-purpose solution for durability.

- If your primary focus is scratching, cutting, or grinding: A diamond's world-class hardness makes it the ideal material for abrasive applications.

- If your primary focus is resisting impact or high pressure: A diamond's brittleness makes it a poor choice; you should look to tougher materials like sapphire, certain ceramics, or high-strength steel alloys.

Ultimately, knowing the difference between hardness and toughness is the key to respecting a material's true capabilities and limitations.

Summary Table:

| Property | Diamond's Characteristic | Why It Matters Under a Press |

|---|---|---|

| Hardness | Extremely High (10 on Mohs scale) | Resists scratching, but irrelevant to crushing force. |

| Toughness | Very Low (Brittle) | Cannot absorb impact energy; leads to catastrophic fracture. |

| Cleavage Planes | Present (Internal weak planes) | Provide a path for cracks to spread easily under pressure. |

Need precision equipment that can handle extreme conditions? At KINTEK, we specialize in high-performance lab equipment and consumables designed for durability and accuracy. Whether you're testing material strength or require robust tools for your research, our solutions are built to meet the demanding needs of modern laboratories. Contact our experts today to find the right equipment for your specific application!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What causes hydraulic pressure spikes? Prevent System Damage from Hydraulic Shock

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing