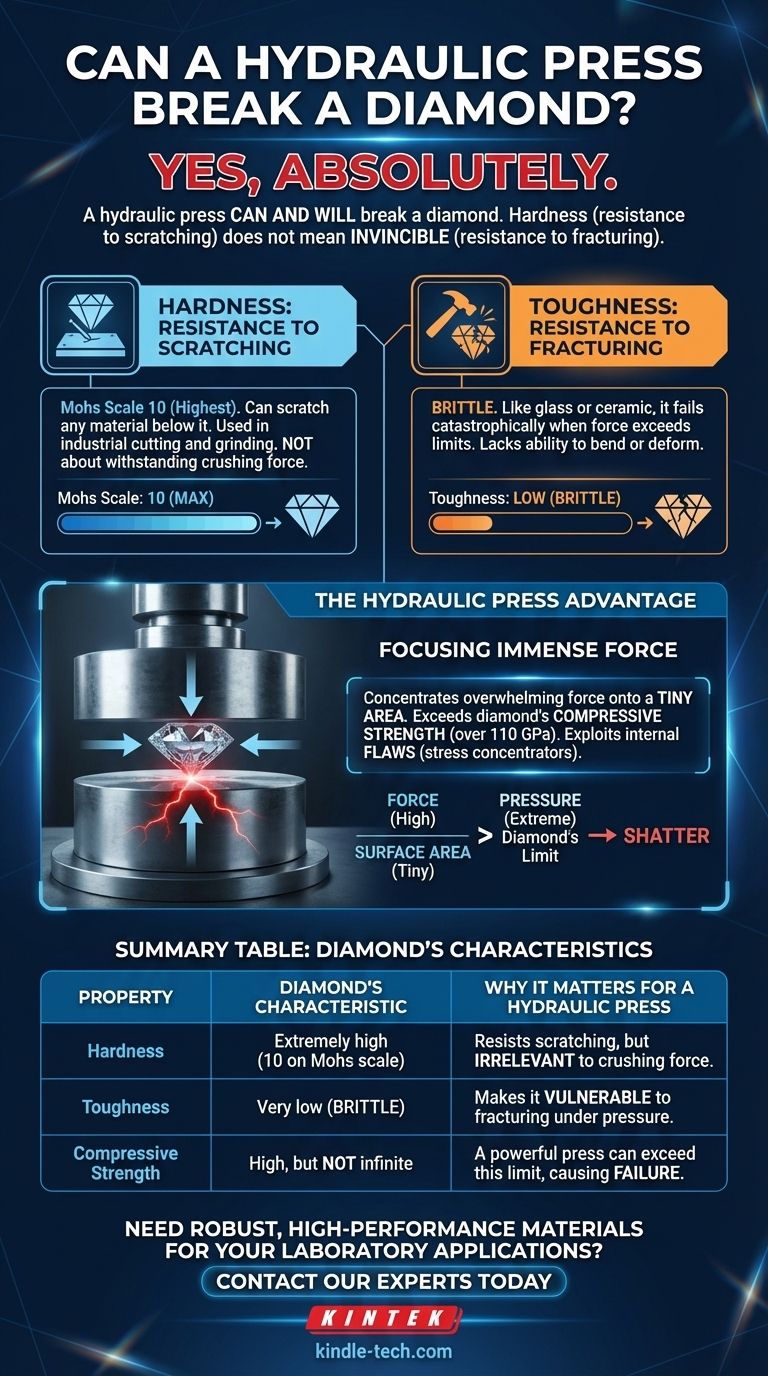

Yes, absolutely. A hydraulic press can and will break a diamond. While a diamond is famously the hardest natural material, its hardness refers to its exceptional resistance to being scratched. It does not mean the diamond is invincible; under the immense, focused force of a hydraulic press, a diamond's structure will fail, and it will shatter.

The core of this issue lies in a common misunderstanding of material properties. We confuse a diamond's incredible hardness (resistance to scratching) with toughness (resistance to fracturing). A diamond is extremely hard, but it is also brittle, making it vulnerable to the crushing power of a press.

The Misconception: Hardness vs. Strength

The statement "a diamond is the hardest material" is true, but its meaning is highly specific. This property is what allows a diamond to cut glass, but it's also why a press can destroy it.

What "Hardness" Really Means

Hardness is a measure of a material's resistance to surface scratching and abrasion. It's most famously measured on the Mohs scale, where diamond sits at a 10, the very top.

This means a diamond can scratch any other material below it on the scale, from steel to quartz. This property is why diamonds are used in industrial cutting and grinding tools.

The Diamond's True Weakness: Brittleness

Toughness, or fracture toughness, is a material's ability to absorb energy and resist fracturing when force is applied. Materials that are not tough are considered brittle.

A diamond is a classic example of a brittle solid. Its rigid atomic lattice is incredibly strong, but it lacks the ability to bend or deform under pressure. Like glass or ceramic, once the force exceeds its structural limit, it fails catastrophically.

Compressive Strength: The Real Test

A hydraulic press isn't trying to scratch the diamond; it's testing its compressive strength—the ability to withstand being crushed.

While a diamond's compressive strength is exceptionally high (over 110 gigapascals), it is not infinite. A powerful hydraulic press can generate more than enough localized pressure to exceed this limit.

How the Hydraulic Press Wins

The victory of the press over the diamond is a straightforward application of physics. It concentrates an overwhelming amount of force onto a tiny area, creating pressure that the diamond's atomic bonds simply cannot endure.

Focusing Immense Force

The fundamental principle of a hydraulic press is to multiply force. This force is then applied by two steel platens, which are much softer than the diamond.

However, the steel's softness is irrelevant. The press concentrates this force onto the small surface area of the diamond, generating pressure that is orders of magnitude higher than what the steel itself is experiencing.

The Critical Point of Failure

As the press applies slow, steady force, the energy builds within the diamond's crystal lattice. The diamond resists until the pressure finds a weak point or simply overwhelms the atomic bonds.

At this moment, all the stored energy is released at once, causing the diamond to shatter, often with explosive force. It doesn't bend, dent, or deform; it breaks completely.

The Role of Imperfections

Nearly all diamonds have tiny internal flaws or surface imperfections. These microscopic weak points act as stress concentrators.

When the press applies force, the stress builds disproportionately around these flaws, providing a starting point for a fracture to begin and spread through the crystal. A theoretically "perfect" diamond would be stronger, but it would still be breakable.

Understanding the Trade-offs

A diamond's properties are a direct result of its atomic structure. Its greatest strength is also the source of its greatest weakness.

Designed for Hardness, Not Toughness

A diamond consists of carbon atoms locked in an incredibly rigid and dense tetrahedral lattice. This structure is what makes it so difficult for another object to dislodge atoms from its surface, giving it supreme hardness.

However, this same rigidity means the structure has no effective way to dissipate energy. Unlike a metal that can bend and deform, a diamond can only do one of two things: resist the force completely or shatter.

The Hammer vs. The Press

You don't need a hydraulic press to break a diamond. A well-aimed strike with a simple hammer can also shatter one. Both methods exploit the diamond's brittleness.

The hammer uses high-velocity impact force, while the press uses low-velocity compressive force. The outcome is the same because both introduce more energy than the brittle crystal lattice can absorb.

Making the Right Choice for Your Goal

Understanding these distinctions is crucial for applying materials science in the real world, whether in industry or for personal items.

- If your primary focus is scratch resistance: A diamond is unparalleled. This is why it is used for high-end watch faces and industrial cutting tools.

- If your primary focus is resisting impact or crushing force: A material with high toughness, like engineered steel alloys or even some polymers, is far superior to a diamond.

- If you own diamond jewelry: Remember that its hardness protects it from everyday scratches from keys or countertops, but a sharp blow against a hard surface can still chip or fracture it.

Ultimately, appreciating a material requires understanding its complete profile—not just its most famous characteristic.

Summary Table:

| Property | Diamond's Characteristic | Why It Matters for a Hydraulic Press |

|---|---|---|

| Hardness | Extremely high (10 on Mohs scale) | Resists scratching, but irrelevant to crushing force. |

| Toughness | Very low (brittle) | Makes it vulnerable to fracturing under pressure. |

| Compressive Strength | High, but not infinite | A powerful press can exceed this limit, causing failure. |

Need robust, high-performance materials for your laboratory applications? At KINTEK, we specialize in providing durable lab equipment and consumables designed to withstand the demanding conditions of research and industry. Our expertise ensures you get the right tools that balance strength, hardness, and toughness for your specific needs. Don't let material misconceptions hinder your progress—contact our experts today to find the perfect solution for your laboratory!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the highest pressure in a hydraulic press? Unlock the True Power of Force Multiplication

- How does a press machine work? Harnessing Force Multiplication for Industrial Power

- What are the uses of hydraulic press in everyday life? The Invisible Force Shaping Your World

- What can you do with a hydraulic press? A Versatile Tool for Industrial and Scientific Applications

- What is forging in hydraulic press? Master Controlled Metal Forming with Sustained Pressure

- What is the alternative to XRF? Choose the Right Elemental Analysis for Your Lab

- What is the construction of a hydraulic press? The Core Components Explained

- What is the most likely cause of excessive temperature in the hydraulic fluid would be? A Faulty Relief Valve