Yes, a hydraulic press can absolutely crush steel. The immense power of a hydraulic press comes from its ability to multiply force using a confined, incompressible fluid. This principle allows a relatively small input force to be converted into a massive output force capable of deforming or crushing materials with high compressive strength, including solid steel.

The core concept isn't whether it's possible—it is—but whether a specific hydraulic press is designed with enough tonnage to overcome the compressive strength of a specific piece of steel. The power comes from Pascal's Law, which allows force to be multiplied to incredible levels.

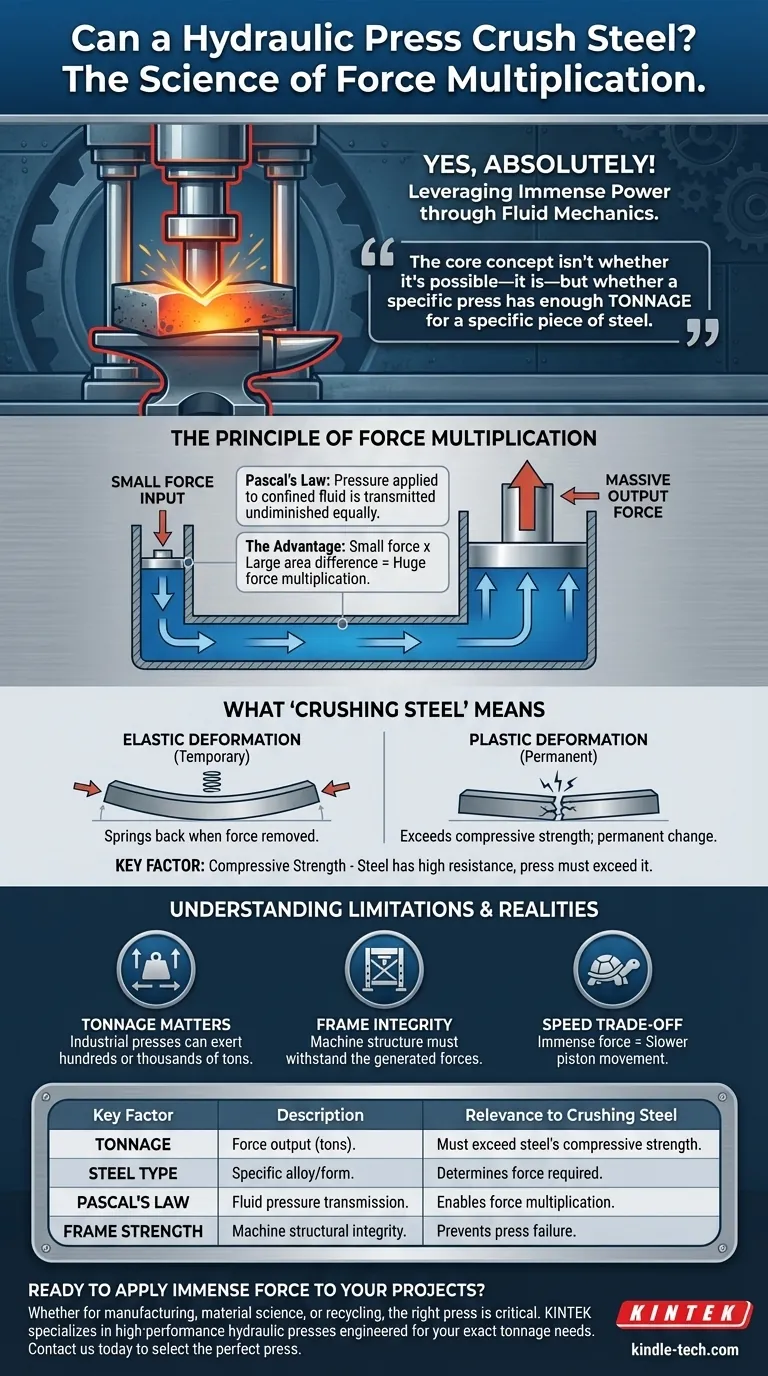

The Principle of Force Multiplication

The magic of a hydraulic press lies in a fundamental principle of fluid mechanics. It's not about brute strength from a motor, but about clever engineering.

Pascal's Law Explained

At the heart of the system is Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simpler terms, if you push on a fluid in a sealed container, the pressure increases equally everywhere inside that container.

The Role of Pistons

A hydraulic press uses two pistons of different sizes in a shared, sealed system filled with an incompressible fluid (usually oil).

A small force is applied to the smaller input piston. This creates pressure in the fluid. According to Pascal's Law, this exact same pressure is then applied to the much larger output piston.

Because the output piston has a much larger surface area, that same pressure results in a much larger output force. This is the force multiplication effect. It's like using a very long lever, but with fluid instead of a solid bar.

Why Fluid is the Key

The system works because the hydraulic oil is incompressible. When you apply pressure, the fluid doesn't get smaller; it perfectly transfers that energy from the small piston to the large one.

What "Crushing Steel" Actually Means

The term "crushing" involves overcoming the fundamental properties of the steel itself. A press must be powerful enough to push the material past its breaking point.

Exceeding Compressive Strength

Every material has a compressive strength—the maximum amount of crushing force it can withstand before it fails or deforms permanently.

Steel has exceptionally high compressive strength. The hydraulic press must generate a force greater than the steel's internal structural resistance to initiate a crush.

Elastic vs. Plastic Deformation

Initially, as the press applies force, the steel will deform elastically, meaning it would spring back to its original shape if the force were removed.

To "crush" the steel, the press must apply enough force to push it past its elastic limit and into plastic deformation, where the change in shape is permanent.

Not All Steel is the Same

The amount of force required varies dramatically based on the type of steel. A press that can easily crush a hollow tube of mild steel may be completely ineffective against a solid block of hardened tool steel or a specialized alloy.

Understanding the Limitations and Realities

While theoretically possible, practical limitations determine whether a given press can crush a piece of steel. The answer always comes down to the numbers.

It's All About Tonnage

The power of a hydraulic press is measured in tonnage—the amount of force it can exert. A small 10-ton shop press used for bearings will not crush a solid steel billet.

Industrial presses used for forging and shaping steel components can be rated for hundreds or even thousands of tons of force. The machine must be matched to the task.

The Machine Must Withstand Itself

An often-overlooked factor is the frame of the press. The machine's structure must be strong enough to contain the immense forces it generates.

If the press is not built to handle the required tonnage, it will break itself before it crushes a piece of steel that is beyond its capacity.

Speed is the Trade-off

The trade-off for immense force multiplication is speed. To move the large output piston a small distance, the small input piston must travel a much longer distance. This is why hydraulic presses are incredibly powerful but often move quite slowly.

Applying This Principle to Your Goal

Understanding the relationship between force, area, and material strength allows you to see how this technology is applied to different challenges.

- If your primary focus is industrial manufacturing (e.g., stamping car doors): You need a press with tonnage precisely engineered to exceed the steel's plastic deformation point for consistent, repeatable shaping.

- If your primary focus is material science: You use a carefully calibrated hydraulic press to test the exact compressive strength of different alloys, measuring the precise force at which a material fails.

- If your primary focus is simple demolition or recycling: You need a press with sufficient tonnage to simply crush and compact various steel objects, where precision is less important than raw power.

By harnessing the physics of a simple fluid, a hydraulic press demonstrates how a well-engineered system can generate force powerful enough to reshape the strongest of materials.

Summary Table:

| Key Factor | Description | Relevance to Crushing Steel |

|---|---|---|

| Tonnage | The force output of the press, measured in tons. | Must exceed the steel's compressive strength to cause permanent deformation or failure. |

| Steel Type | The specific alloy and form (e.g., mild steel vs. hardened tool steel). | Determines the compressive strength and the force required to crush it. |

| Pascal's Law | Principle that pressure in a confined fluid is transmitted equally. | Enables force multiplication from a small input piston to a large output piston. |

| Machine Frame Strength | The structural integrity of the press itself. | Must be robust enough to withstand the generated force without breaking. |

Ready to apply this immense force to your projects?

Whether you are in industrial manufacturing, material science, or recycling, the right hydraulic press is critical for shaping, testing, or crushing steel effectively. KINTEK specializes in high-performance lab equipment and industrial machinery, offering hydraulic presses engineered for precision, durability, and the exact tonnage you need.

Contact us today via our [#ContactForm] to discuss your specific requirements. Let our experts help you select the perfect press to overcome material challenges and enhance your operational efficiency.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.