Yes, absolutely. Physical Vapor Deposition (PVD) coating is not only possible on stainless steel, but stainless steel is considered one of the most advantageous materials for the process. Its inherent properties allow for a strong, direct bond with the coating material, creating a highly durable and aesthetically pleasing finish without the need for intermediate layers.

The core takeaway is that the combination of PVD and stainless steel is not just a functional pairing; it's a synergistic one. Stainless steel's natural durability and corrosion resistance make it an ideal base that enhances the PVD process, resulting in a superior final product that is both economically efficient and exceptionally resilient.

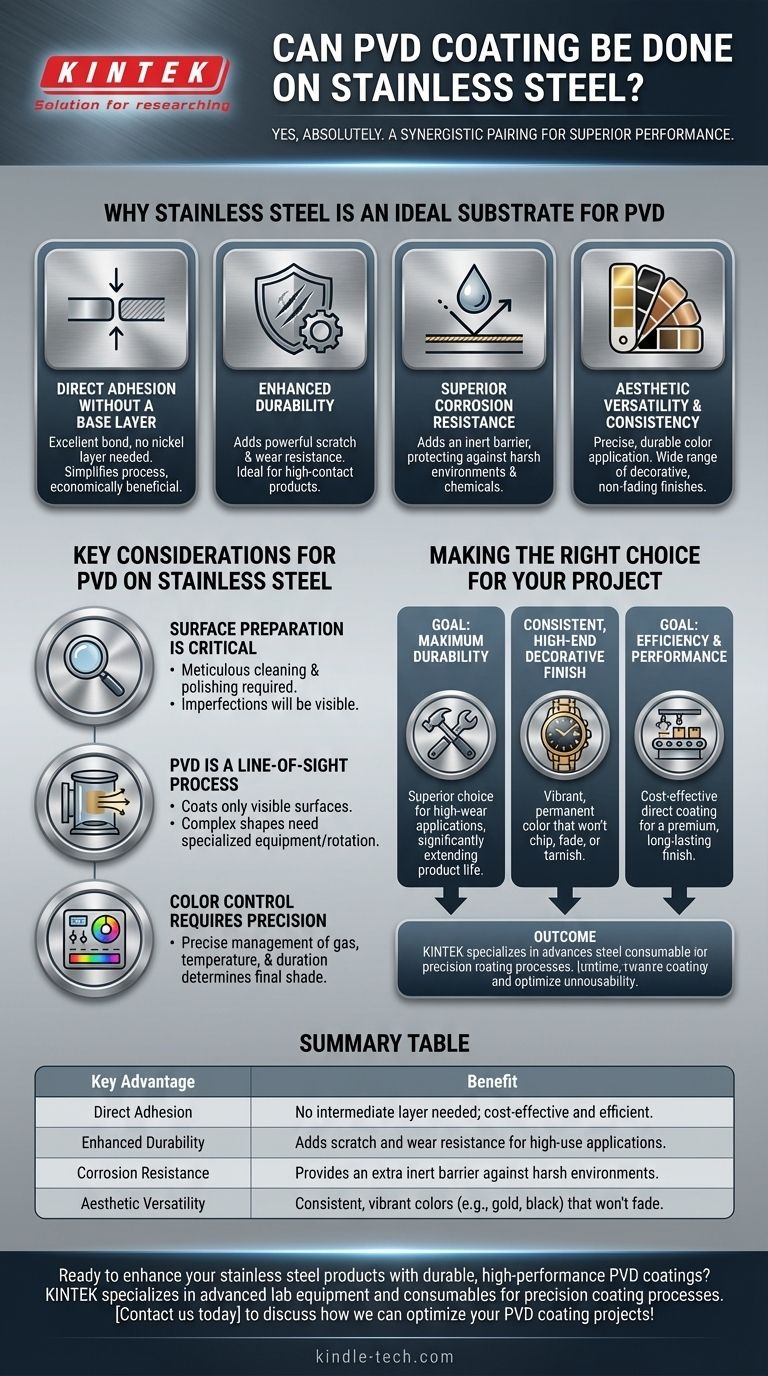

Why Stainless Steel is an Ideal Substrate for PVD

The advantages of using PVD on stainless steel stem from the inherent properties of the metal itself. This combination elevates the performance and appearance of the final product in several key ways.

Direct Adhesion Without a Base Layer

Unlike many other metals that require a preparatory layer (like nickel), stainless steel allows for excellent direct adherence of the PVD coating. This simplifies the manufacturing process significantly.

By eliminating the need for an intermediate coating, the process becomes faster and more economically beneficial.

Enhanced Durability

Stainless steel is already known for its strength. Applying a PVD coating, which is typically a very hard ceramic material, adds a powerful layer of scratch and wear resistance.

This makes the combination ideal for products that experience frequent contact or friction, such as watch casings, fixtures, or industrial components.

Superior Corrosion Resistance

While stainless steel is inherently corrosion-resistant due to its chromium content, the PVD coating adds another inert barrier. This non-reactive layer provides an extra degree of protection against harsh environmental conditions, chemicals, and salt.

Aesthetic Versatility and Consistency

PVD provides the ability to apply a thin film of color with exceptional precision. This ensures the final product's color perfectly and consistently matches the desired specification.

This process can produce a wide range of decorative finishes—such as gold, black, bronze, and rose gold—that are far more durable than traditional plating or painting.

Key Considerations for PVD on Stainless Steel

While the combination is highly effective, achieving a flawless result requires attention to specific details. Understanding these factors is crucial for success.

Surface Preparation is Critical

The PVD process does not hide imperfections. The final finish is a direct reflection of the underlying stainless steel surface.

Therefore, the steel must be meticulously cleaned and polished before entering the PVD chamber. Any scratches, oils, or blemishes on the substrate will be visible in the final coated product.

PVD is a Line-of-Sight Process

The vaporized coating material travels in a straight line within the vacuum chamber. This means it can only coat surfaces that it can "see."

Complex shapes with deep recesses or intricate internal geometries may be challenging to coat evenly without specialized equipment and fixture rotation.

Color Control Requires Precision

While PVD offers excellent color consistency, achieving a specific shade requires precise control over the deposition parameters. Factors like the gas mixture, temperature, and duration of the process all impact the final color and must be carefully managed.

Making the Right Choice for Your Project

Choosing to use PVD on your stainless steel product depends on your primary goal.

- If your primary focus is maximum durability and wear resistance: The hardness of a PVD coating makes it a superior choice for high-wear applications, significantly extending the product's life.

- If your primary focus is a consistent, high-end decorative finish: PVD provides a vibrant, permanent color that will not chip, fade, or tarnish like paint or traditional plating.

- If your primary focus is efficiency and performance: The ability to coat stainless steel directly without a base layer makes PVD a cost-effective method for achieving a premium, long-lasting finish.

Ultimately, combining PVD with stainless steel leverages the best qualities of both materials to create a product of superior quality and performance.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Direct Adhesion | No intermediate layer needed; cost-effective and efficient. |

| Enhanced Durability | Adds scratch and wear resistance for high-use applications. |

| Corrosion Resistance | Provides an extra inert barrier against harsh environments. |

| Aesthetic Versatility | Consistent, vibrant colors (e.g., gold, black) that won’t fade. |

Ready to enhance your stainless steel products with durable, high-performance PVD coatings? KINTEK specializes in advanced lab equipment and consumables for precision coating processes. Whether you're in manufacturing, jewelry, or industrial components, our solutions ensure superior adhesion, color consistency, and longevity. Contact us today to discuss how we can optimize your PVD coating projects!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating