Yes, you can absolutely coat something in a layer of real, synthetic diamond. This isn't a simple paint or plating process; it is a highly advanced manufacturing technique that grows a thin film of actual diamond, atom by atom, directly onto an object's surface. The most common method is known as Chemical Vapor Deposition (CVD), which transforms carbon-containing gas into a solid, crystalline diamond film.

The ability to coat objects in diamond is a powerful engineering tool, used not for decoration but to impart its extraordinary properties—like extreme hardness and thermal conductivity—onto other materials. However, the process is complex, expensive, and subject to significant technical limitations.

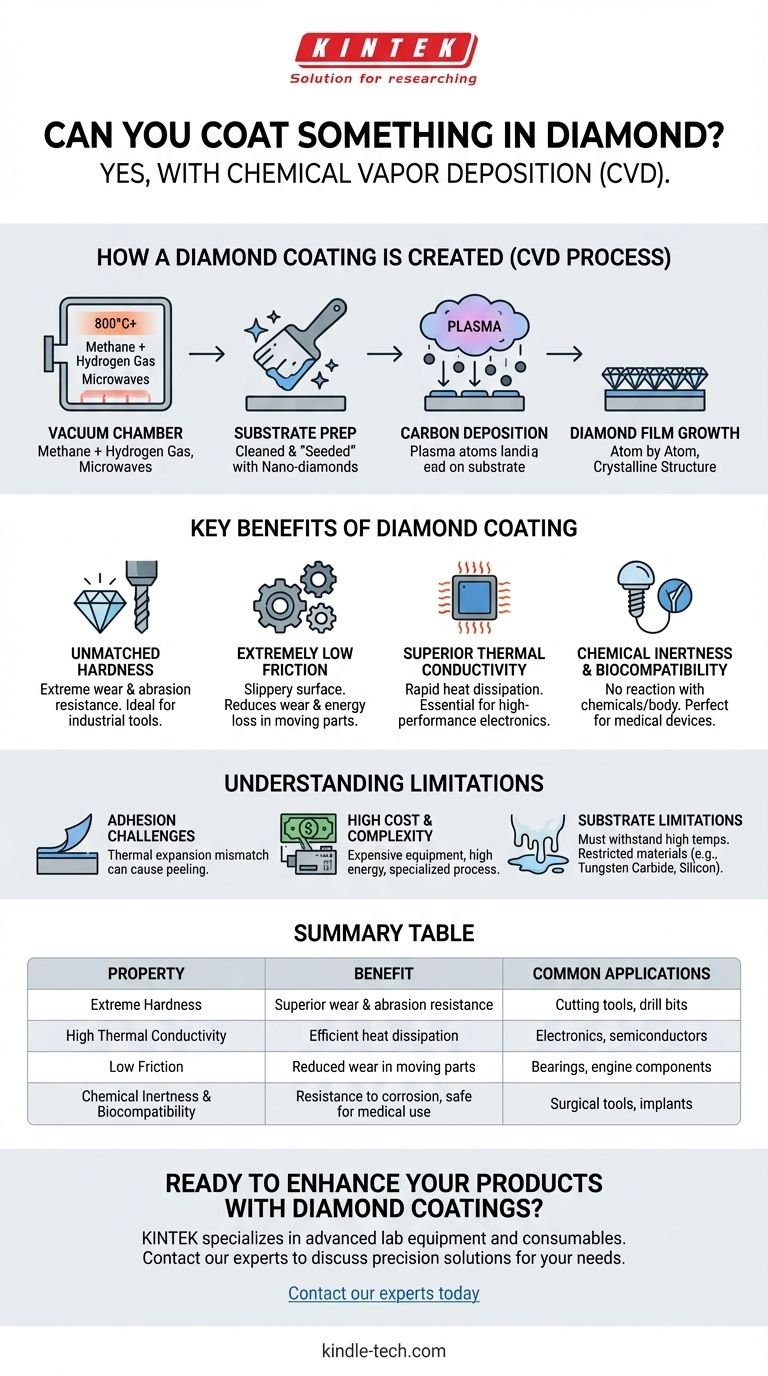

How a Diamond Coating Is Actually Created

The process of applying a diamond coating is more akin to growing a crystal than it is to painting. It requires a controlled environment and specialized equipment to build a flawless diamond layer.

The Core Technology: Chemical Vapor Deposition (CVD)

The primary method used is Chemical Vapor Deposition (CVD). A substrate (the object to be coated) is placed inside a vacuum chamber.

The chamber is heated to very high temperatures, often over 800°C (1472°F), and a carbon-rich gas, like methane, is introduced along with hydrogen.

A source of energy, typically microwaves, is used to break down the gas molecules. This allows pure carbon atoms to settle and bond onto the substrate's surface, slowly building up a crystalline diamond structure.

The Critical Role of the Substrate

The material being coated, known as the substrate, is crucial. It must be able to withstand the high temperatures of the CVD process without melting or deforming.

Furthermore, the surface must be meticulously cleaned and often "seeded" with nano-diamond particles. These tiny seed crystals act as nucleation sites, providing a template for the new diamond film to begin growing uniformly.

The Result: A True Diamond Film

The end result is not a "diamond-like" material but a film of polycrystalline diamond—a mosaic of tiny, interlocked diamond crystals. It possesses the same chemical structure and physical properties as a mined diamond.

Why Diamond Coatings Are So Valuable

Applying a diamond film can radically transform the performance of a base material. The benefits are tied directly to the intrinsic properties of diamond itself.

Unmatched Hardness and Wear Resistance

This is the most well-known property. A diamond coating makes surfaces incredibly resistant to scratching, abrasion, and wear. This is essential for industrial cutting tools, drill bits, and grinding wheels, dramatically extending their operational lifespan.

Extremely Low Friction

Diamond has one of the lowest coefficients of friction of any solid material. A diamond-coated surface is exceptionally "slippery," which is ideal for reducing wear and energy loss in moving parts, such as bearings or engine components.

Superior Thermal Conductivity

Diamond is the best known thermal conductor—five times better than copper. This allows it to rapidly draw heat away from a source. This property is vital for high-performance electronics, where it's used as a heat spreader for powerful computer chips.

Chemical Inertness and Biocompatibility

Diamond is chemically inert, meaning it does not react with most acids, bases, or other corrosive substances. It is also biocompatible, so the human body does not reject it, making it an excellent coating for medical implants and surgical tools.

Understanding the Trade-offs and Limitations

While powerful, diamond coating is not a universal solution. The process involves significant engineering challenges that limit its widespread application.

The Challenge of Adhesion

Getting the diamond film to stick firmly to the substrate is the single biggest challenge. Materials expand and contract at different rates when heated. If the thermal expansion mismatch between the diamond and the substrate is too great, the coating can crack or peel off.

High Cost and Complexity

The CVD process requires expensive, specialized equipment, high-purity gases, and a significant amount of energy. This makes true diamond coating a cost-prohibitive process for all but the most high-performance applications.

Substrate Material Limitations

The high temperatures required for CVD mean that many common materials, such as plastics, aluminum, or standard steel, cannot be coated without being damaged or melting. The choice of substrate is restricted to materials like tungsten carbide, silicon, or ceramics.

Not to Be Confused with DLC

Many products are coated with Diamond-Like Carbon (DLC), not true diamond. DLC is a hard, low-friction carbon film, but its atoms are arranged amorphously (randomly) rather than in a crystal lattice. DLC is an excellent and more cost-effective coating, but it does not possess the full thermal or hardness properties of true crystalline diamond.

Making the Right Choice for Your Goal

Deciding between true diamond, DLC, or another coating depends entirely on the technical requirements and budget of the application.

- If your primary focus is extreme industrial performance: True diamond coating is the gold standard for cutting tools, wear parts, and drills where maximum lifespan and performance are non-negotiable.

- If your primary focus is durable consumer goods: For items like high-end watches, knives, or firearm components, Diamond-Like Carbon (DLC) provides excellent hardness and a premium finish at a much more accessible cost.

- If your primary focus is advanced electronics: The unparalleled thermal conductivity of a true CVD diamond film is essential for managing heat in next-generation semiconductors and high-power lasers.

- If your primary focus is biomedical applications: The absolute chemical inertness and biocompatibility of a pure diamond coating make it a leading choice for long-term medical implants where reliability is paramount.

Ultimately, diamond coating is a specialized engineering solution used to bestow the superlative properties of diamond onto materials that could otherwise never possess them.

Summary Table:

| Property | Benefit | Common Applications |

|---|---|---|

| Extreme Hardness | Superior wear and abrasion resistance | Cutting tools, drill bits |

| High Thermal Conductivity | Efficient heat dissipation | Electronics, semiconductors |

| Low Friction | Reduced wear in moving parts | Bearings, engine components |

| Chemical Inertness & Biocompatibility | Resistance to corrosion, safe for medical use | Surgical tools, implants |

Ready to enhance your products with the ultimate performance of diamond coatings? KINTEK specializes in advanced lab equipment and consumables for cutting-edge applications. Our expertise in materials science can help you leverage CVD diamond technology to achieve superior hardness, thermal management, and longevity for your industrial tools, electronics, or medical devices. Contact our experts today to discuss how we can support your project with precision solutions tailored to your laboratory needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition