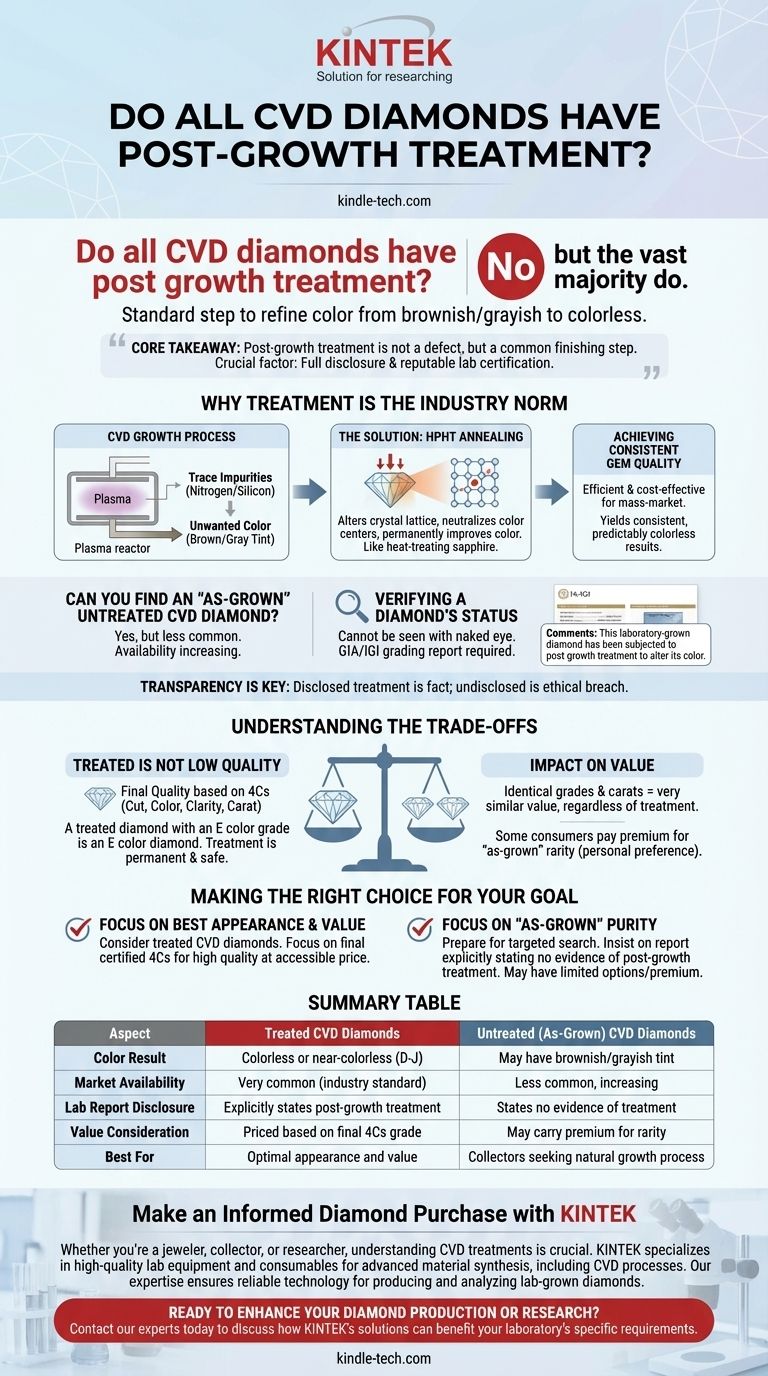

No, not all CVD diamonds undergo post-growth treatment, but the vast majority of those intended for gem-quality jewelry do. It is a standard and often necessary step in the manufacturing process to refine the diamond's color from a brownish or grayish tint to a desirable colorless or near-colorless grade.

The core takeaway is that post-growth treatment is not a defect, but rather a common and accepted finishing step for most CVD diamonds. The crucial factor for a buyer is not whether a diamond was treated, but that the treatment is fully disclosed and the final quality is certified by a reputable lab.

Why Treatment is the Industry Norm for CVD Diamonds

To understand why treatment is so common, you have to understand the chemistry of the CVD (Chemical Vapor Deposition) growth process itself. The goal is to create a perfect carbon lattice, but minor impurities are often unavoidable.

The Challenge of Unwanted Color

The CVD growth chamber is a highly controlled environment, but trace elements can still be incorporated into the diamond's crystal structure as it forms.

These impurities create "color centers" that absorb light, resulting in a visible tint. The most common issues are a brownish hue caused by nitrogen and other structural defects, or a grayish tint caused by silicon impurities.

The Solution: HPHT Annealing

The primary post-growth treatment used on CVD diamonds is HPHT annealing. This involves placing the diamond in a machine that subjects it to High-Pressure and High-Temperature conditions.

This process doesn't add anything to the diamond. Instead, it alters the diamond's crystal lattice on an atomic level, effectively neutralizing the color centers and permanently improving the diamond's color. It's best understood as a final refinement, much like heat treating a sapphire.

Achieving Consistent Gem Quality

It is often more efficient and cost-effective for manufacturers to grow diamonds quickly and then treat them to achieve the target color.

Growing a perfect, colorless "as-grown" CVD diamond is possible, but it requires a much slower and more expensive process. For mass-market production, the grow-and-treat model yields more consistent and predictable results.

Can You Find an "As-Grown" Untreated CVD Diamond?

Yes, untreated gem-quality CVD diamonds exist, but they are less common in the market. As technology improves, their availability is increasing, but treatment remains the standard.

Verifying a Diamond's Status

You cannot tell if a diamond has been treated just by looking at it. The only way to know for sure is through a grading report from a reputable gemological laboratory like the GIA or IGI.

These reports will explicitly state whether the diamond shows evidence of post-growth treatment. If it has been treated, the comments section might note something like, "This laboratory-grown diamond has been subjected to post-growth treatment to alter its color."

The Importance of Transparency

The critical issue is not the treatment itself, but the disclosure of it. Any reputable vendor will sell CVD diamonds with a corresponding lab report that documents their characteristics, including any treatments. An undisclosed treatment is a serious ethical breach; a disclosed one is simply a fact about the stone's origin.

Understanding the Trade-offs

Viewing treatment as a simple "good" vs. "bad" issue is a common mistake. The reality is more nuanced and depends on your priorities as a buyer.

Treatment is Not a Sign of Low Quality

A treated CVD diamond is not inherently inferior to an untreated one. The final quality of any diamond—lab-grown or natural—is judged by its 4Cs (Cut, Color, Clarity, and Carat) after all processes are complete.

A treated diamond with an E color grade is, for all practical purposes, an E color diamond. The treatment is permanent and does not impact the diamond's stability or durability.

Impact on Value

The market price for a CVD diamond is based on its final, certified attributes. Two diamonds with identical grades and carat weights will have very similar values, regardless of whether one was treated and the other was "as-grown."

Some consumers may place a premium on an "as-grown" stone for its perceived purity, but this is a personal preference rather than an objective measure of quality or value.

Making the Right Choice for Your Goal

Ultimately, the decision rests on what you value most. The key is to make an informed choice based on transparent, certified information.

- If your primary focus is on the best possible appearance and value: You should confidently consider treated CVD diamonds. Focus on the final color and clarity grades on the certificate, as this is the industry standard for producing beautiful, high-quality stones at an accessible price.

- If your primary focus is on acquiring a completely "as-grown" stone: Be prepared for a more targeted search. Insist on a grading report that explicitly states there is no evidence of post-growth treatment, and understand that this may limit your options or come at a slight premium.

Your final decision should be guided by the certified quality of the diamond, not by the specific steps in its manufacturing journey.

Summary Table:

| Aspect | Treated CVD Diamonds | Untreated (As-Grown) CVD Diamonds |

|---|---|---|

| Color Result | Colorless or near-colorless (D-J) | May have brownish/grayish tint |

| Market Availability | Very common (industry standard) | Less common, increasing with technology |

| Lab Report Disclosure | Explicitly states post-growth treatment | States no evidence of treatment |

| Value Consideration | Priced based on final 4Cs grade | May carry premium for rarity |

| Best For | Optimal appearance and value | Collectors seeking natural growth process |

Make an Informed Diamond Purchase with KINTEK

Whether you're a jeweler, collector, or researcher, understanding CVD diamond treatments is crucial for selecting the right gem for your needs. At KINTEK, we specialize in providing high-quality lab equipment and consumables that support advanced material synthesis, including CVD processes.

Our expertise ensures you have access to reliable technology for producing and analyzing lab-grown diamonds. Let us help you achieve consistent, high-quality results with transparent manufacturing insights.

Ready to enhance your diamond production or research? Contact our experts today to discuss how KINTEK's solutions can benefit your laboratory's specific requirements.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- Why are metal catalysts essential for creating graphene via the CVD process? Unlock High-Quality Graphene Synthesis

- Why is chemical vapor deposition important? Unlock Atomic-Level Precision for Your Materials

- What is the use of DC sputtering? Deposition of Conductive Thin Films for High-Tech Applications

- What is vapour deposition method for nanoparticle synthesis? A Guide to High-Purity Material Creation

- What is the main difference between ALD and CVD? Precision vs. Speed in Thin Film Deposition

- How plasma is formed in RF sputtering? Unlocking the Process for Insulating Materials

- How does the Hot Filament Chemical Vapour Deposition (HFCVD) process work? Master High-Quality Diamond Synthesis

- What is the typical particle size range obtained from CVD? Achieve Nanometer Precision and High Purity