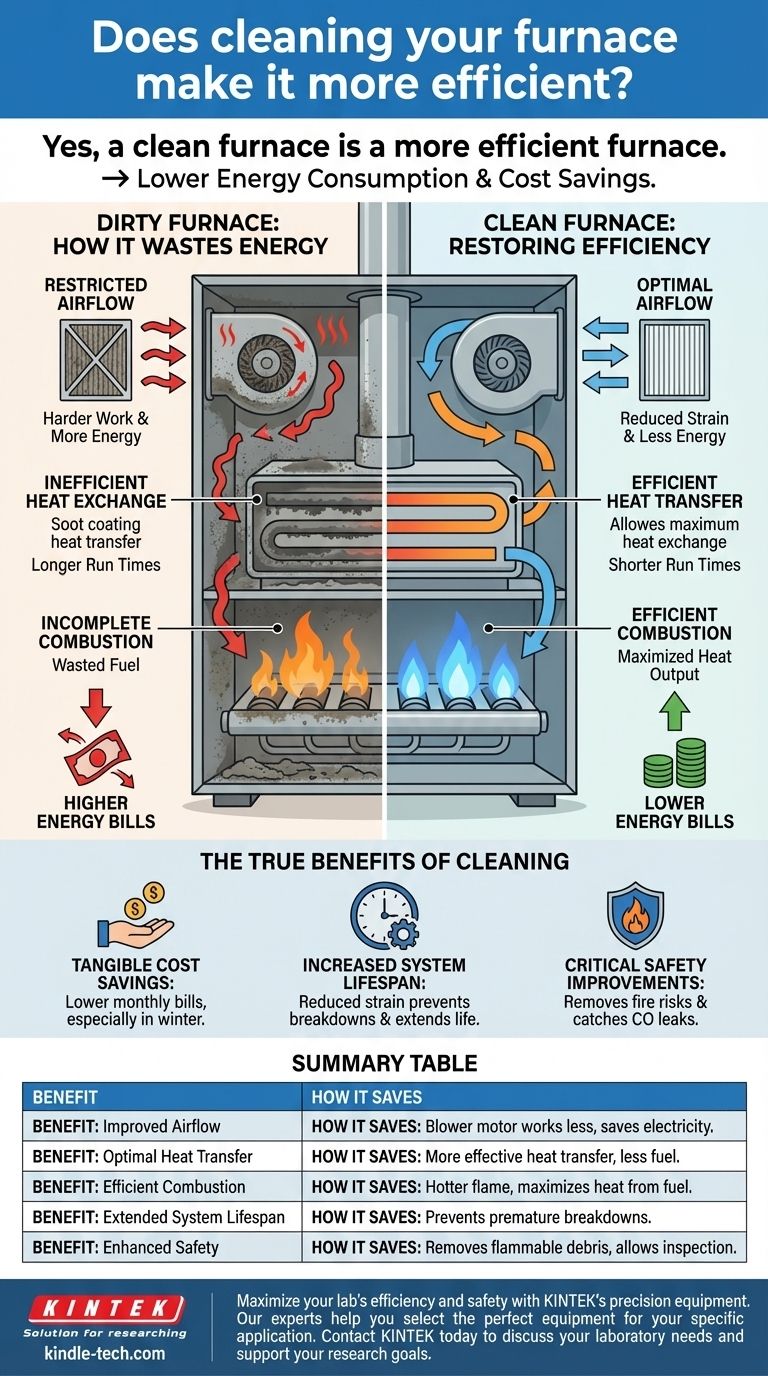

Yes, a clean furnace is a more efficient furnace. When critical components like the boiler, burners, and ductwork are free of dust and debris, your heating system does not have to run as long or work as hard to heat your home, directly translating into lower energy consumption and cost savings.

The core issue is simple: dirt, dust, and soot act as insulators and obstructions. Cleaning a furnace removes these barriers, allowing it to transfer heat and move air according to its original design specifications, restoring its peak efficiency.

How a Dirty Furnace Wastes Energy

A furnace is a system of interconnected parts, and neglect in one area creates a cascading effect that undermines the entire operation. The goal is to transfer heat to the air and distribute that air throughout your home; dirt compromises both of these functions.

The Problem of Restricted Airflow

The most common point of failure is airflow. Dust and debris build-ups force the system's fan, or blower motor, to work significantly harder to push air.

This obstruction typically occurs in three key places: the air filter, the blower wheel itself, and the ductwork. A clogged filter is the most frequent culprit, acting like a dam that chokes the system and strains the motor.

The Impact on Heat Exchange

The central component for heat transfer is the heat exchanger. In a gas furnace, burners heat this metal chamber, and the blower then pushes air across its hot surface.

When a layer of soot or dust coats the heat exchanger, it acts as a layer of insulation. This prevents heat from transferring efficiently to the air, forcing the furnace to burn more fuel and run longer to satisfy the thermostat's call for heat.

The Effect on Fuel Combustion

For gas or oil furnaces, clean burners are essential for efficient fuel combustion. Burners clogged with debris can produce an inefficient, wavering flame.

This incomplete combustion fails to generate the maximum possible heat from the fuel being used. A professional cleaning ensures the burners are clear, resulting in a clean, hot flame that maximizes the energy output of every unit of fuel.

Understanding the True Benefits of Cleaning

While improved efficiency is the primary goal, the positive outcomes extend to the system's longevity and your home's safety.

Tangible Cost Savings

An efficient furnace runs for shorter cycles and burns fuel more effectively. This directly reduces your monthly gas, oil, or electricity bill, especially during the coldest months of the year.

Increased System Lifespan

When a furnace is forced to overcome clogged filters and dirty components, it places immense strain on parts like the blower motor and safety switches. This constant overwork leads to premature wear and tear.

Regular cleaning reduces this strain, helping to prevent costly breakdowns and extend the operational life of your entire HVAC system.

Critical Safety Improvements

A furnace cleaning is also a safety inspection. A technician will clear away flammable debris that can accumulate near the burner assembly, reducing fire risk.

Crucially, they inspect the heat exchanger for cracks or rust. A compromised heat exchanger could leak dangerous carbon monoxide into your home's air, a risk that routine maintenance is designed to catch.

Making the Right Choice for Your Goal

Your approach to furnace maintenance depends on your immediate goal, from basic upkeep to ensuring long-term performance.

- If your primary focus is routine upkeep: Regularly replace your furnace air filter every 1-3 months to maintain proper airflow.

- If your primary focus is maximum efficiency and safety: Schedule a professional cleaning and tune-up with a qualified HVAC technician annually.

- If your primary focus is solving high energy bills on an old system: Understand that while cleaning will help, it can't fix an outdated, inefficient design; a system replacement may be the most cost-effective long-term solution.

Ultimately, keeping your furnace clean is one of the most effective ways to ensure it operates efficiently, reliably, and safely.

Summary Table:

| Benefit of a Clean Furnace | How It Saves Energy & Money |

|---|---|

| Improved Airflow | Blower motor doesn't have to work as hard, reducing strain and electricity use. |

| Optimal Heat Transfer | Clean heat exchanger transfers heat more effectively, requiring less fuel. |

| Efficient Combustion | Clean burners produce a hotter flame, maximizing heat output from fuel. |

| Extended System Lifespan | Reduced wear and tear prevents premature breakdowns and costly repairs. |

| Enhanced Safety | Removes flammable debris and allows for inspection of critical components like the heat exchanger. |

Maximize your lab's efficiency and safety with KINTEK's precision equipment. Just as a clean furnace ensures optimal performance for your home, the right lab equipment is crucial for accurate, reliable, and safe results. KINTEK specializes in high-quality lab furnaces, ovens, and consumables designed for peak efficiency and longevity. Let our experts help you select the perfect equipment for your specific application. Contact KINTEK today to discuss your laboratory needs and discover how we can support your research and development goals.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the different types of laboratory furnaces? Find the Perfect Fit for Your Application

- What is the difference between a box furnace and a muffle furnace? Choose the Right Lab Furnace for Your Application

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab

- What is a laboratory furnace called? A Guide to Muffle and Tube Furnaces

- What are the conditions for a muffle furnace? Ensure Safety, Performance, and Longevity