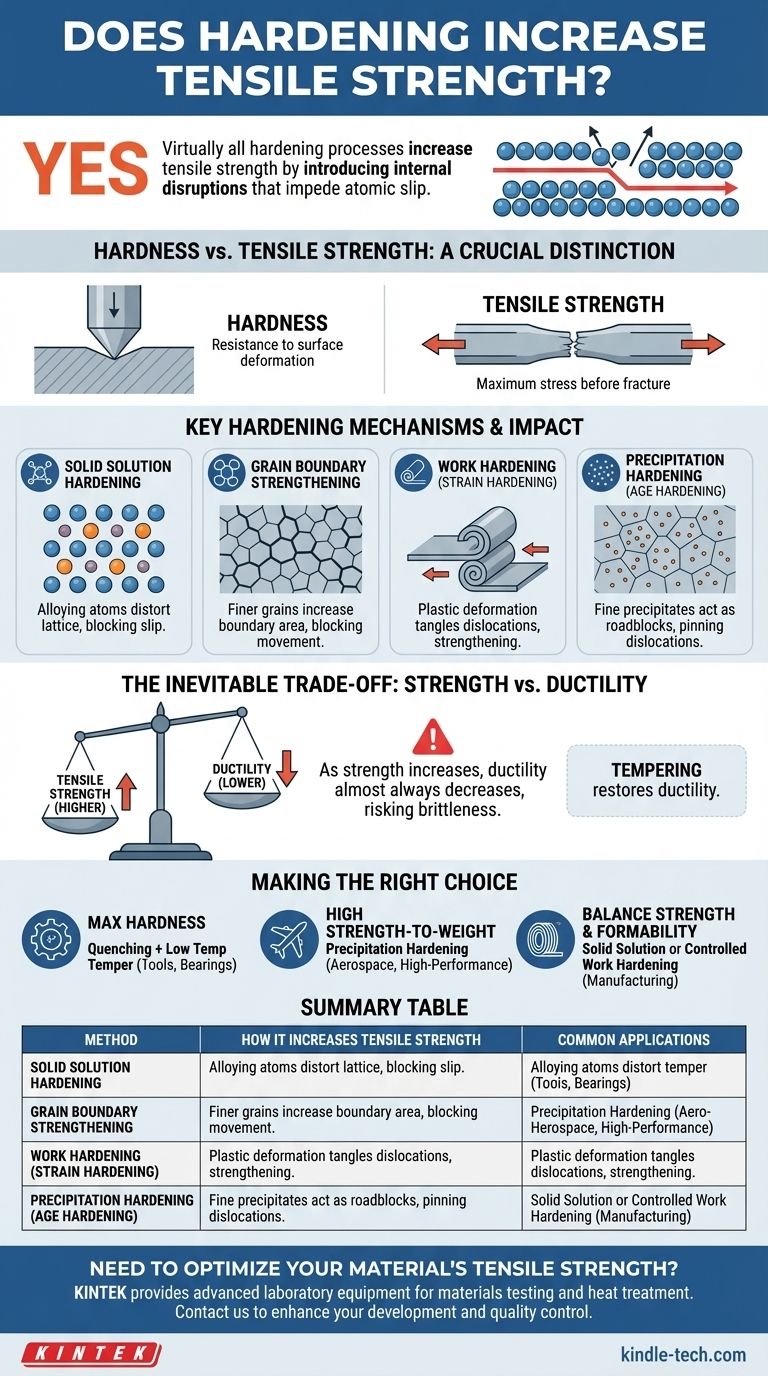

Yes, virtually all hardening processes are designed to increase a material's tensile strength. Hardening works by intentionally introducing disruptions into the material's internal crystal structure. These disruptions make it more difficult for the atomic layers to slip past one another, which is the physical mechanism of deformation. This increased resistance to deformation is what we measure as higher tensile strength.

The core principle is this: hardening methods reorganize a material’s internal structure—at the atomic or grain level—to impede the movement that allows for bending and stretching. This resistance directly translates to higher tensile strength, but almost always at the cost of reduced ductility.

Hardness vs. Tensile Strength: A Crucial Distinction

While closely related and often increasing together, hardness and tensile strength are not the same property. Understanding the difference is key to selecting the right material and process.

What is Hardness?

Hardness measures a material's resistance to localized surface deformation, such as scratching, abrasion, or indentation. It is primarily a surface-level property.

What is Tensile Strength?

Tensile strength (or Ultimate Tensile Strength, UTS) measures the maximum stress a material can withstand while being pulled or stretched before it fractures. It is a measure of the material's bulk structural integrity.

Key Hardening Mechanisms and Their Impact

Hardening isn't a single action but a category of metallurgical processes. Each method increases tensile strength by creating different types of internal obstacles.

Solid Solution Hardening

This process involves adding atoms of an alloying element to the base metal. As noted in the reference, these "foreign" atoms don't fit perfectly in the crystal lattice.

This imperfect fit creates internal stress and distorts the atomic planes, making it much harder for them to slip past one another under load, thereby increasing tensile strength.

Grain Boundary Strengthening

Materials are made of many individual crystals, or "grains." The interfaces between these grains are called grain boundaries.

These boundaries act as natural barriers to dislocation movement. By making the grains smaller (a finer grain structure), you increase the total area of these grain boundaries, creating more obstacles and significantly increasing the material's strength. Processes like sintering directly influence this grain structure.

Work Hardening (Strain Hardening)

This is a mechanical process where a metal is strengthened by plastic deformation, such as rolling, drawing, or bending it at room temperature.

The physical act of deforming the material creates a cascade of new dislocations within the crystal structure. These dislocations become tangled, impeding each other's movement and making the material stronger and harder.

Precipitation Hardening (Age Hardening)

This is a heat treatment technique that creates tiny, uniformly dispersed particles of a secondary phase within the primary metal's grain structure.

These fine precipitates act like microscopic roadblocks, effectively pinning dislocations in place and providing a powerful strengthening effect. This is a common method for high-strength aluminum, magnesium, and nickel alloys.

Understanding the Inevitable Trade-off: Strength vs. Ductility

You cannot fundamentally change a material's properties without consequences. The most critical trade-off in hardening is sacrificing ductility to gain strength.

The Inverse Relationship

Ductility is the measure of a material's ability to deform under tensile stress—think of its ability to stretch or bend before it breaks.

The very mechanisms that increase strength (pinning dislocations, stressing the lattice) also restrict the plastic deformation that defines ductility. As a result, as tensile strength increases, ductility almost always decreases.

The Risk of Brittleness

A material with very low ductility is considered brittle. While incredibly strong, a fully hardened, brittle material may fracture suddenly under load with little to no warning or deformation.

This is why processes like tempering are often performed after hardening. Tempering slightly reduces the peak hardness and strength but restores a crucial amount of ductility and toughness, preventing catastrophic failure.

Making the Right Choice for Your Goal

The optimal approach depends entirely on the component's intended application.

- If your primary focus is maximum hardness and wear resistance: Use heat treatments like quenching followed by a low-temperature temper for tools and bearing surfaces.

- If your primary focus is high strength-to-weight ratio: Use precipitation hardening, which is ideal for aerospace and high-performance applications.

- If your primary focus is balancing strength with formability: Use solid solution hardening (by choosing the right alloy) or controlled work hardening during the manufacturing process.

Ultimately, hardening is about engineering a material's internal structure to achieve the precise balance of properties required for its specific job.

Summary Table:

| Hardening Method | How It Increases Tensile Strength | Common Applications |

|---|---|---|

| Solid Solution Hardening | Adds alloying atoms to distort the crystal lattice, impeding dislocation movement. | Alloy steels, stainless steels |

| Grain Boundary Strengthening | Creates finer grains with more boundaries to block dislocation motion. | Sintered metals, fine-grained alloys |

| Work Hardening | Introduces dislocations via plastic deformation, tangling them to strengthen the material. | Cold-rolled sheets, drawn wires |

| Precipitation Hardening | Forms fine precipitates that pin dislocations, providing significant strength. | Aerospace alloys, high-strength aluminum |

Need to Optimize Your Material's Tensile Strength?

Hardening is a precise science that requires the right equipment and expertise. At KINTEK, we specialize in providing advanced laboratory equipment and consumables for materials testing and heat treatment processes. Whether you're developing high-strength alloys or need precise control over your hardening cycles, our solutions help you achieve the perfect balance of strength and ductility for your specific application.

Contact us today to discuss how our lab equipment can enhance your material development and quality control processes. Let's strengthen your success together!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the FDM extrusion process? A Complete Guide to Layer-by-Layer 3D Printing

- What are the disadvantages of a screw compressor? Key Trade-offs to Consider Before Buying

- What is bio-oil mainly produced by? Converting Biomass to Renewable Fuel via Fast Pyrolysis

- How thick is gold sputtering? Achieve Precise Coatings from Ångstroms to Microns

- How to calculate coating thickness? Select the Right Method for Accurate Results

- What are the results of sintering? From Powder to High-Strength Solid Parts

- What is the standard for elemental analysis? A Guide to Accurate, Traceable Results

- What is the main problem with biomass energy? The Sustainability Contradiction Explained