In short, no. Increasing hydraulic pressure does not directly increase the speed of an actuator like a cylinder or motor. The speed of a hydraulic system is determined by the flow rate—the volume of fluid moved over time. Pressure is the component that provides the force or torque needed to move the load.

The most common misunderstanding in hydraulics is confusing force with speed. The core principle to remember is that pressure dictates force, while flow rate dictates speed. To solve a speed problem, you must address the system's flow, not its pressure setting.

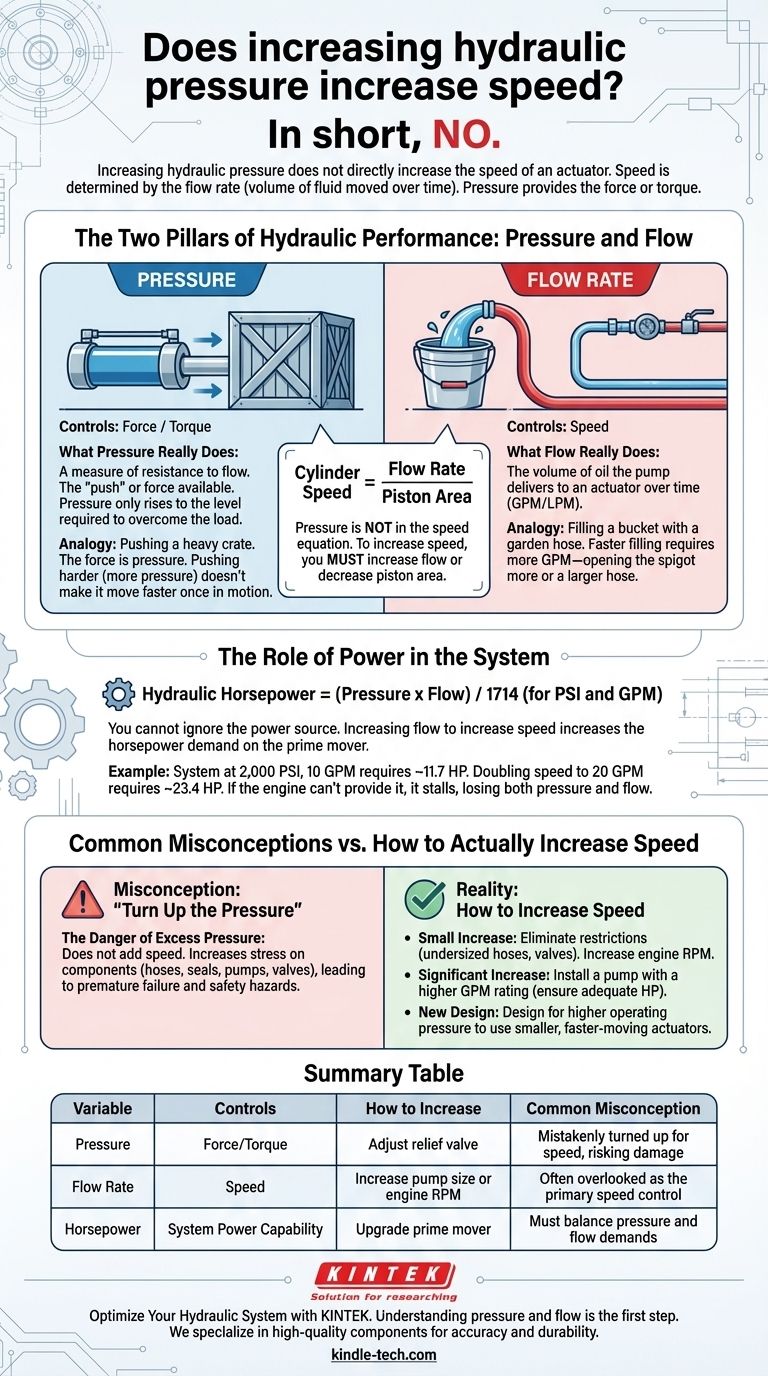

The Two Pillars of Hydraulic Performance: Pressure and Flow

To properly diagnose and improve a hydraulic system, you must treat pressure and flow as two separate variables that perform two distinct jobs.

What Pressure Really Does

Pressure is a measure of resistance to flow. It is the "push" or force available to do work. The pressure in a system only rises to the level required to overcome the load it's moving.

Think of trying to push a heavy crate. The force you apply is the pressure. If the crate is light, you don't have to push very hard. If it's heavy, you must push much harder. Simply deciding to push harder (increasing the pressure setting) won't make the crate move faster once it's already in motion.

What Flow Really Does

Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), is the variable that determines speed. It is the volume of oil the pump delivers to an actuator.

Imagine filling a bucket with a garden hose. The speed at which the bucket fills is a direct result of the flow rate from the hose. To fill it faster, you need more GPM—either by opening the spigot more or by using a larger hose. The actuator (a cylinder or motor) is the bucket; to make it move faster, you must supply it with more fluid per minute.

The Equation for Speed

This relationship isn't theoretical; it's mathematical. The speed of a hydraulic cylinder is calculated directly from the flow rate and the cylinder's physical dimensions.

Cylinder Speed = Flow Rate / Piston Area

As you can see, pressure is not a variable in the speed calculation. The only way to increase speed is to increase the flow rate or decrease the piston area.

The Role of Power in the System

Pressure and flow are not entirely independent; they are linked by the requirements of hydraulic horsepower. Understanding this connection is crucial to avoid system-level problems.

Why You Can't Ignore the Power Source

The power required by a hydraulic system is a product of both pressure and flow. The formula is:

Hydraulic Horsepower = (Pressure x Flow) / 1714 (when using PSI and GPM)

This means you cannot simply increase one variable without consequence. If you install a larger pump to increase flow (for more speed), the horsepower demand on the prime mover (engine or electric motor) will increase proportionally.

A Practical Example

If your system runs at 2,000 PSI with a 10 GPM pump, it requires about 11.7 HP. If you want to double the speed by installing a 20 GPM pump, your horsepower requirement will double to 23.4 HP. If your engine can't provide that power, it will stall or bog down, and you will lose both pressure and flow.

Common Misconceptions and Trade-offs

Simply "turning up the pressure" at the system's relief valve is a common but misguided reaction to poor performance. This approach not only fails to solve the speed issue but can introduce serious risks.

The Danger of Excess Pressure

Increasing the pressure setting beyond the design specification does not add speed. It only increases the stress on every component in the system—hoses, seals, pumps, and valves. This can lead to premature component failure, catastrophic oil leaks, and significant safety hazards.

When Higher Pressure Indirectly Helps Speed

There is one scenario where higher pressure relates to speed, but it's in the design phase, not the tuning phase. A system designed to operate at a higher pressure (e.g., 5,000 PSI vs. 3,000 PSI) can use smaller-diameter cylinders to achieve the same amount of force.

Because a smaller cylinder has less internal volume, it requires a lower flow rate (GPM) to extend or retract at the same speed. This allows for a more compact, efficient, and often more responsive system design, but it is not something you can change by adjusting a valve on existing equipment.

How to Actually Increase Hydraulic Speed

To make your system faster, you must focus on the true driver of speed: flow rate. Here are the correct approaches based on your goal.

- If your primary focus is a small speed increase: Investigate and eliminate restrictions in the system. Undersized hoses, fittings, or restrictive valves can rob flow. Increasing the engine's RPM (if possible) will also increase the flow from a fixed-displacement pump.

- If your primary focus is a significant speed increase: Your solution is to increase the system's flow rate. This almost always requires installing a pump with a higher GPM rating and ensuring your engine or electric motor has enough horsepower to support it.

- If you are designing a new system for high speed: Consider designing for a higher operating pressure. This allows for the use of smaller, faster-moving actuators for a given force requirement, creating a more responsive and efficient system from the ground up.

By focusing on flow rate for speed and pressure for force, you gain precise control over your hydraulic system's performance and ensure its long-term reliability.

Summary Table:

| Variable | Controls | How to Increase | Common Misconception |

|---|---|---|---|

| Pressure | Force/Torque | Adjust relief valve | Mistakenly turned up for speed, risking damage |

| Flow Rate | Speed | Increase pump size or engine RPM | Often overlooked as the primary speed control |

| Horsepower | System Power Capability | Upgrade prime mover | Must balance pressure and flow demands |

Optimize Your Hydraulic System with KINTEK

Struggling with slow hydraulic equipment or unreliable performance? Understanding the precise roles of pressure and flow is the first step toward a solution. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including hydraulic system components designed for accuracy and durability.

Whether you're maintaining existing machinery or designing a new system for maximum efficiency, our expertise ensures you get the right components for your specific laboratory needs. We help you:

- Select the correct pumps and actuators for optimal flow rates

- Identify and replace restrictive hoses or fittings

- Ensure your system has adequate horsepower for desired performance

Don't let hydraulic misconceptions slow down your operations. Contact our experts today for a personalized consultation and discover how KINTEK can enhance your lab's hydraulic performance and reliability.

Visual Guide

Related Products

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation