To reduce a furnace's temperature rise, you must increase the volume of air moving across its heat exchanger. A high temperature rise is a critical warning sign that your furnace is struggling to "breathe," which can lead to overheating, safety shutdowns, and premature component failure. The solution is rarely about turning down the heat; it’s about improving airflow.

A furnace's temperature rise is a direct symptom of its airflow. Instead of viewing it as a heat problem, treat it as an airflow problem. The core task is to identify and remove any restrictions that prevent air from moving freely through the system.

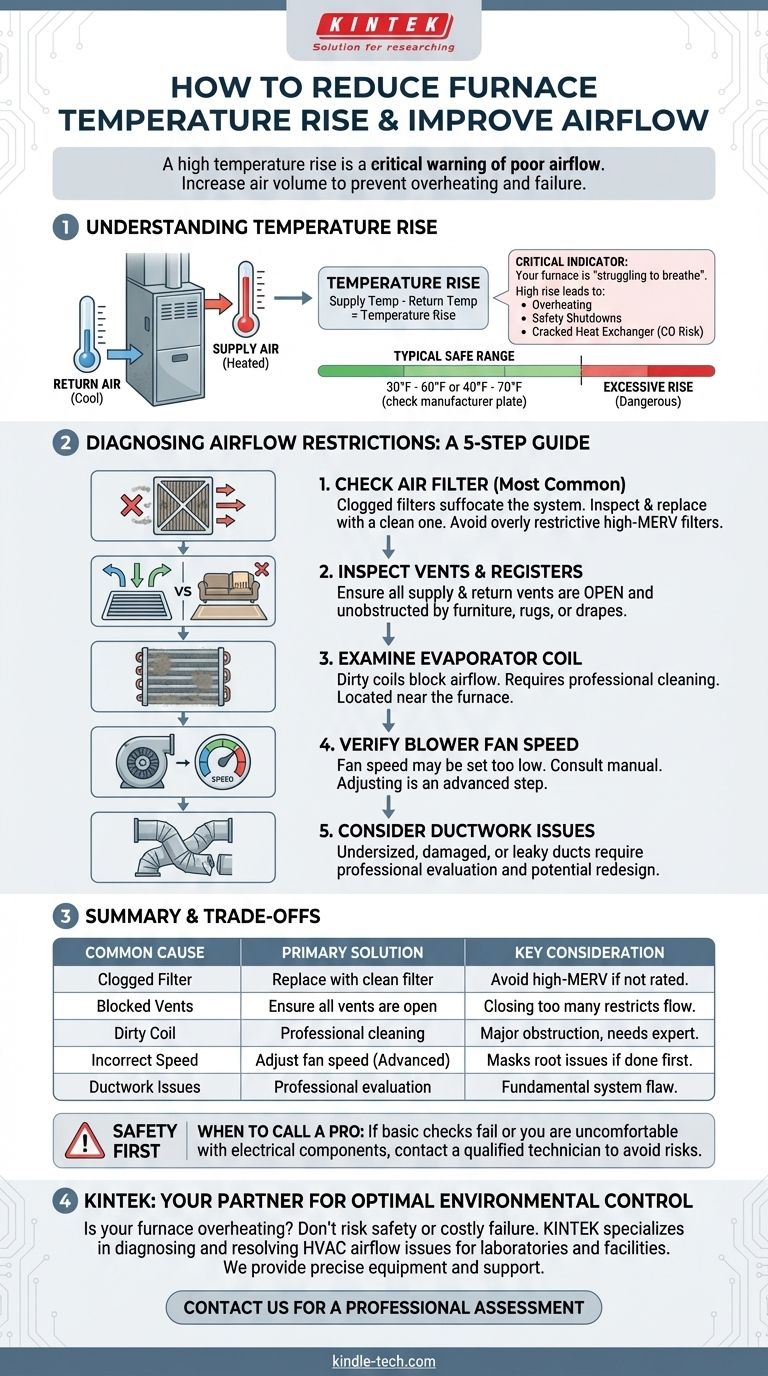

What is Temperature Rise and Why Does It Matter?

Before fixing the problem, it's essential to understand what you're measuring and why it's a vital health indicator for your heating system.

Defining Temperature Rise

Temperature rise is the difference between the air temperature going into your furnace (the return air) and the heated air coming out (the supply air).

It's measured by placing a thermometer in the return ductwork near the furnace and another in the supply plenum just after the furnace. The formula is simple: Supply Air Temperature - Return Air Temperature = Temperature Rise.

Finding the Correct Range for Your Furnace

Every furnace is designed to operate within a specific temperature rise range. This information is printed on the manufacturer's data plate, usually located on a sticker inside the furnace cabinet.

The acceptable range might look something like "30°F - 60°F" or "40°F - 70°F". If your measured rise is above this range, the system is operating outside of its design parameters.

The Dangers of an Excessive Rise

When airflow is too low, the heat produced by the burners isn't carried away fast enough. This causes heat to build up inside the furnace, leading to several serious problems.

The most immediate issue is tripping the high-limit switch, a safety device that shuts the furnace down to prevent overheating. This results in intermittent heating and a system that can't run a full cycle.

Over time, chronic overheating can stress the heat exchanger, causing cracks. A cracked heat exchanger can allow dangerous combustion gases, including carbon monoxide (CO), to mix with your home's air.

A Step-by-Step Guide to Diagnosing Airflow Issues

A high temperature rise is almost always caused by an airflow restriction. To solve it, you must find the bottleneck. Follow these steps, starting with the easiest and most common culprits.

Step 1: Check the Air Filter (The Most Common Culprit)

A clogged air filter is the number one cause of high temperature rise. It effectively suffocates the system, dramatically reducing the amount of air the blower fan can pull through.

Your first action should always be to inspect and, if necessary, replace the air filter with a clean one.

Step 2: Inspect Vents and Registers

Your furnace can't push air into rooms if the pathways are blocked. Walk through your home and ensure all supply and return registers are open and not obstructed by furniture, rugs, or drapes.

Closing too many vents in unused rooms can also severely restrict system airflow, concentrating all the heat into a smaller area and driving up the temperature rise.

Step 3: Examine the Evaporator Coil

If you have a central air conditioning system, an evaporator coil sits on top of or just downstream from your furnace. This coil can become caked with dust and debris, creating a massive obstruction to airflow.

Visually inspecting the coil may require removing an access panel. If it's dirty, it must be professionally cleaned, as this is a delicate and often difficult-to-access component.

Step 4: Verify the Blower Fan Speed

Furnace blowers are often multi-speed motors. The speed is typically set via color-coded wires on the main control board. The furnace may be set to a speed that is too low for the system's needs.

Consulting your furnace's installation manual can help you identify if the fan is set to the correct speed for heating mode. Adjusting this is a more advanced step and may be best left to a technician.

Step 5: Consider the Ductwork Itself

In some cases, the problem is the ductwork system. It may be undersized for the furnace, have too many sharp turns, or have collapsed or disconnected sections in a crawlspace or attic. This is a fundamental design issue that requires professional evaluation.

Understanding the Trade-offs and Cautions

While the goal is to lower the temperature rise, how you achieve it has implications for the system's overall performance and safety.

The Pitfall of High-MERV Filters

High-efficiency air filters (MERV 11 and above) are excellent at capturing small particles, but they are also more restrictive to airflow.

Using a filter with a MERV rating that is too high for your system can create the very problem you're trying to solve. Always use a filter that meets, but doesn't drastically exceed, your furnace manufacturer's recommendation.

Blower Speed Is a Solution, But Not Always the First Solution

Increasing the blower speed will definitively lower the temperature rise. However, if you do this without clearing an obstruction like a dirty filter or coil, you are only masking the root problem.

This forces the motor to work harder, increasing energy consumption and noise levels, while the underlying restriction remains. Always clear obstructions first.

When to Call a Professional (Safety First)

While checking filters and vents is safe for any homeowner, tasks involving the furnace cabinet should be approached with caution.

If you are not comfortable working with electrical components or if the problem persists after checking the basics, it's time to call a qualified HVAC technician. They have the tools and expertise to safely diagnose issues with the blower, control board, and heat exchanger.

Making the Right Adjustment for Your System

Your approach should be dictated by the problem's complexity and your comfort level with the equipment.

- If you are a homeowner performing routine maintenance: Start with the simplest fixes like replacing the filter and ensuring all registers are open and unobstructed.

- If the initial checks don't solve the issue: Your next step is to investigate potential obstructions at the evaporator coil or, if you're comfortable, verify the furnace's blower speed setting against its manual.

- If the temperature rise is still too high: This points to a more fundamental issue like undersized ductwork or a failing component, which requires a professional diagnosis.

Restoring proper airflow is the single most effective way to ensure your furnace operates safely, efficiently, and reliably for years to come.

Summary Table:

| Common Cause of High Temperature Rise | Primary Solution | Key Consideration |

|---|---|---|

| Clogged Air Filter | Replace with clean, manufacturer-recommended filter | Avoid overly restrictive high-MERV filters |

| Blocked Vents/Registers | Ensure all supply and return vents are open and unobstructed | Closing too many vents can restrict airflow |

| Dirty Evaporator Coil | Professional cleaning required | A major obstruction that needs expert attention |

| Incorrect Blower Fan Speed | Adjust speed setting per furnace manual (advanced) | Masking other issues if done first; increases noise/energy use |

| Undersized or Damaged Ductwork | Professional evaluation and potential redesign | A fundamental system design issue |

Is your furnace overheating or shutting down unexpectedly? Don't risk safety hazards like carbon monoxide leaks or costly component failure. The expert team at KINTEK specializes in diagnosing and resolving HVAC airflow issues for laboratories and facilities. We provide precise equipment and consumables to maintain optimal environmental control. Contact us today for a professional assessment to ensure your heating system operates safely and efficiently!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is high temperature sintering of ceramics? Transform Powder into Dense, High-Performance Components

- Is pyrolysis of plastic harmful to the environment? It Depends on How You Manage the Outputs

- How much sample is needed for XRF? Focus on Quality, Not Quantity, for Accurate Results

- How hot can a metal surface get in the sun? The Surprising Science Behind Extreme Heat

- Can you provide a typical example of the calcination process? Discover the Limestone to Lime Transformation

- What is the name of the industrial furnace? A Guide to Classifying Heating Equipment

- What is the importance of biomass pyrolysis? Turn Waste into Fuel, Carbon Sequestration, and More

- Why is a benchtop drying oven utilized at 90°C for N,S-TiO2/SSA synthesis? Ensure Catalyst Stability and Reusability