To choose the right press, you must first ignore the machines themselves and instead define your specific operational requirements. The correct choice depends entirely on the application you need to perform, the materials you will be working with, and the scale of your production. Key specifications like force, size, and control systems are simply a reflection of these core needs.

The most common mistake is shopping for a press based on a single specification like tonnage. The key is to reverse your thinking: clearly define the job to be done, and the right machine will become self-evident.

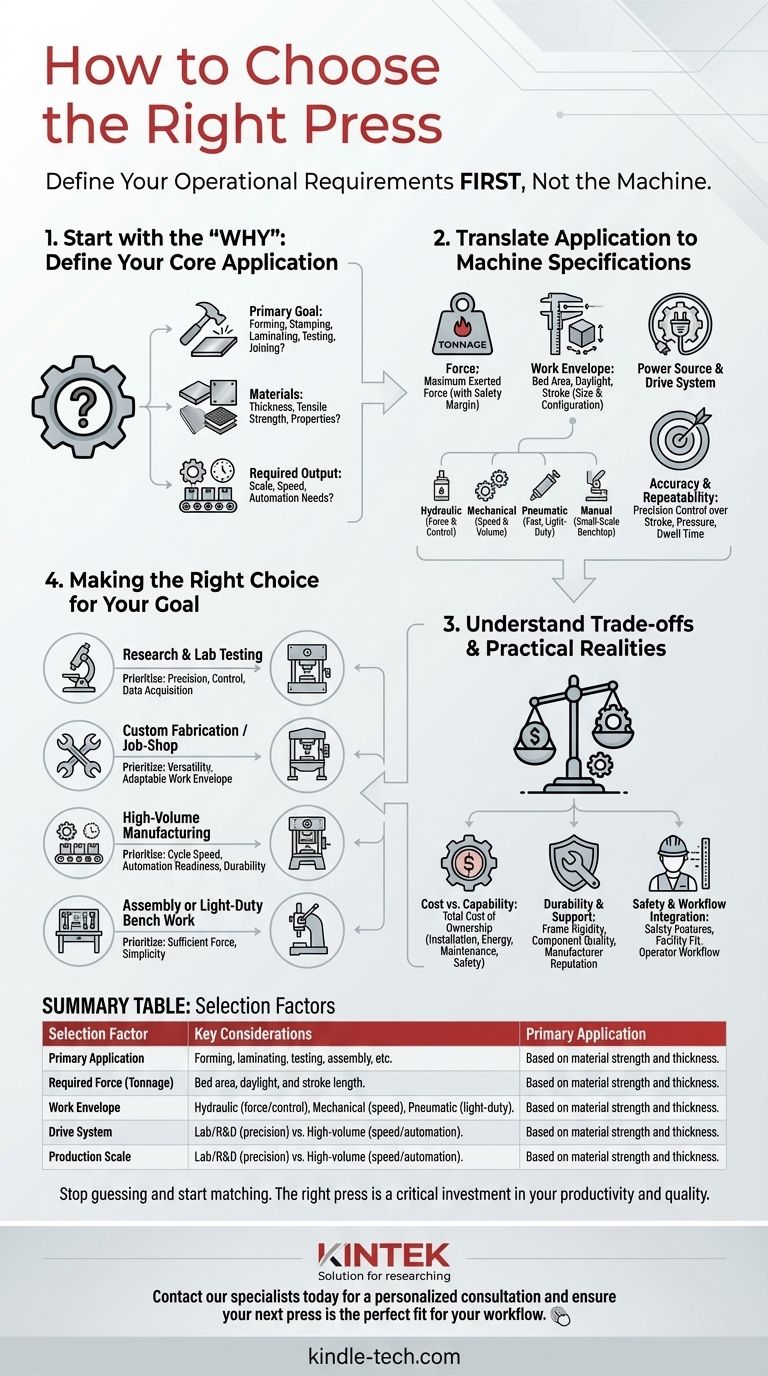

Start with the "Why": Defining Your Core Application

Before you can evaluate any piece of equipment, you must have an exact understanding of the work it will perform. This is the most critical phase of the selection process.

What Is Your Primary Goal?

A press is a tool for applying controlled force. You must identify the specific type of work you are doing. Common applications include forming or stamping metal, laminating materials, compressing powders, conducting destructive material testing, or joining components. Each goal requires different characteristics.

What Materials Are You Using?

The properties of your workpiece dictate the press's requirements. Working with thick steel requires immense force (tonnage), while composites or plastics may require less force but demand precise temperature and pressure control over time.

What Is Your Required Output?

The scale and speed of your operation are crucial. A research lab performing a few tests per day has vastly different needs than a production line manufacturing thousands of parts per hour. This factor will heavily influence the required automation and drive system.

Translating Application to Machine Specifications

Once you have defined your operational needs, you can begin to match them to the technical specifications of a press.

Force (Tonnage)

This is the maximum force the press can exert and is the most common starting point. It is determined by your material's thickness and tensile strength, as well as the complexity of the operation. Always calculate the required tonnage for your most demanding job and add a safety margin.

Size and Configuration (The "Work Envelope")

This refers to the physical space available for your work. Key dimensions include the bed area (the length and width of the working surface), the daylight (the maximum vertical space for your tooling), and the stroke (how far the ram can travel). Your tooling and parts must fit comfortably within this envelope.

Power Source and Drive System

The mechanism that generates the force is a primary differentiator.

- Hydraulic presses use fluid pressure and offer exceptional force and precise control, making them highly versatile for forming, molding, and testing.

- Mechanical presses use a flywheel and clutch to deliver force in a rapid stroke, making them ideal for high-speed, high-volume stamping and punching.

- Pneumatic presses use air pressure for fast, repeatable strokes at lower forces, suitable for assembly, punching, and marking.

- Manual (Arbor) presses are human-powered and used for small-scale benchtop work like seating bearings or light assembly.

Accuracy and Repeatability

For high-quality output, especially in research or precision manufacturing, the press must perform the same way every time. This involves precise control over the stroke position, the applied pressure, and the dwell time (how long pressure is held).

Understanding the Trade-offs and Practical Realities

No machine is perfect for every scenario. Being aware of the inherent compromises is key to making a wise investment.

Cost vs. Capability

The total cost of ownership goes far beyond the initial purchase price. You must factor in installation, energy consumption, required safety systems, and ongoing maintenance. A complex, high-tonnage press may be impressive, but it is an expensive liability if its capabilities are not actually needed.

Durability and Manufacturer Support

A press is a long-term investment that operates under extreme forces. The frame's rigidity and the quality of the components are paramount for a long service life. Investigate the manufacturer's reputation, warranty, and the availability of technical support and spare parts.

Safety and Workflow Integration

A press can be an extremely dangerous machine. Ensure it is equipped with modern safety features like light curtains, dual-hand controls, and emergency stops. Consider how the machine will fit into your facility and the overall operator workflow.

Making the Right Choice for Your Goal

Filter your options by focusing on your primary objective.

- If your primary focus is research and lab testing: Prioritize precision, control, and data acquisition features over raw speed or size.

- If your primary focus is custom fabrication or job-shop work: Seek versatility; a hydraulic press with an adaptable work envelope is often the most effective choice.

- If your primary focus is high-volume, repetitive manufacturing: Emphasize cycle speed, automation readiness, and extreme durability, which often points toward a mechanical press.

- If your primary focus is assembly or light-duty bench work: A pneumatic or manual arbor press provides sufficient force without the complexity and cost of a larger system.

By clearly defining your operational needs first, you transform the complex task of choosing a press into a simple matter of matching specifications.

Summary Table:

| Selection Factor | Key Considerations |

|---|---|

| Primary Application | Forming, laminating, testing, assembly, etc. |

| Required Force (Tonnage) | Based on material strength and thickness. |

| Work Envelope | Bed area, daylight, and stroke length. |

| Drive System | Hydraulic (force/control), Mechanical (speed), Pneumatic (light-duty). |

| Production Scale | Lab/R&D (precision) vs. High-volume (speed/automation). |

Stop guessing and start matching. The right press is a critical investment in your productivity and quality. At KINTEK, we specialize in lab equipment and consumables, serving laboratory needs with precision machinery. Our experts will help you analyze your specific application—whether it's for research, testing, or custom fabrication—to recommend the perfect press for your force, size, and control requirements.

Contact our specialists today for a personalized consultation and ensure your next press is the perfect fit for your workflow.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.