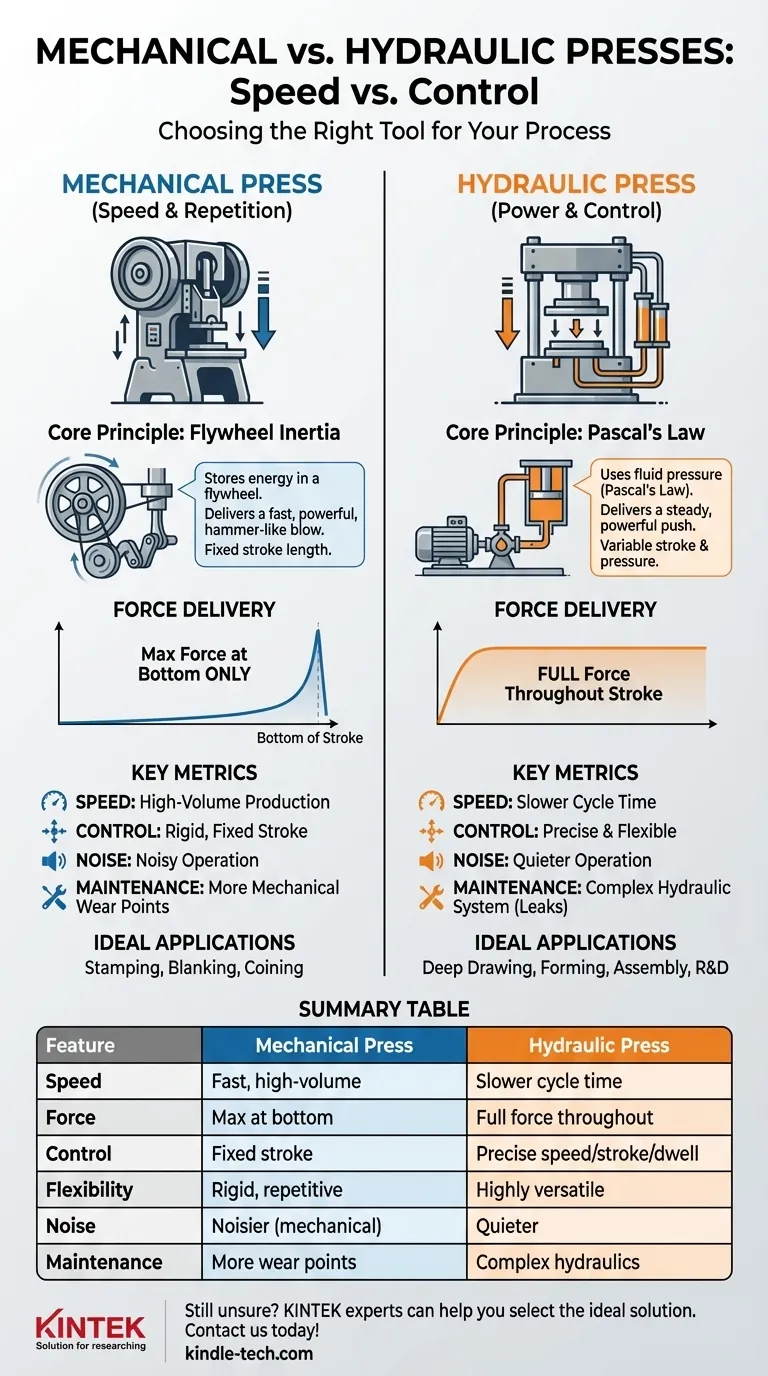

At their core, mechanical and hydraulic presses achieve the same goal through fundamentally different means. A mechanical press uses a flywheel and crank system to deliver a fast, powerful stroke, making it ideal for speed and repetition. In contrast, a hydraulic press uses fluid pressure to generate force, offering superior control and power that can be applied consistently throughout the entire stroke.

The choice between a mechanical and hydraulic press is not about which is "better," but which is right for the specific task. Mechanical presses trade flexibility for speed, while hydraulic presses trade speed for immense force and precise control.

The Core Difference: How They Generate Force

To choose the right press, you must first understand their distinct operating principles. The method of force generation dictates every other performance characteristic.

Mechanical Presses: The Power of Flywheel Inertia

A mechanical press stores energy in a large, spinning flywheel. When activated, a clutch connects the flywheel to a crankshaft or eccentric gear, which drives a ram down in a single, rapid motion.

Think of it like a hammer blow. The force is delivered quickly and is at its absolute maximum only at the very bottom of the stroke. The stroke length is fixed and determined by the physical construction of the crank.

Hydraulic Presses: The Advantage of Pascal's Law

A hydraulic press utilizes Pascal's principle, where an electric motor powers a pump to push incompressible fluid (typically oil) into a cylinder. This pressure acts on a piston, driving the ram down.

This is more like a steady, powerful push than a strike. Full, consistent force is available at any point during the ram's travel, not just at the bottom. The stroke length, pressure, speed, and even dwell time can be precisely controlled by managing the fluid flow with valves.

Comparing Key Performance Metrics

The differences in operating principles lead to significant trade-offs in performance, cost, and complexity.

Speed and Cycle Time

Mechanical presses are the clear winners for speed. Their fixed cycle is inherently fast, making them the standard for high-volume production like blanking, coining, and shallow stamping.

Hydraulic presses are generally slower. The ram must travel, build pressure, retract, and release pressure, resulting in a longer cycle time compared to the simple rotational action of a mechanical press.

Force and Tonnage

Hydraulic presses are unmatched in force capacity and application. They can generate enormous tonnage and, critically, can deliver that full tonnage at any point in the stroke. This is essential for deep-drawing or forming operations that require sustained force over a distance.

A mechanical press only achieves its rated tonnage at the very bottom of its stroke. Its available force is significantly lower at the beginning and middle of its downward motion.

Control and Flexibility

Hydraulic presses offer complete control. The operator can adjust the ram speed, stroke length, pressure, and the duration the pressure is held (dwell time). This makes them incredibly versatile for a wide range of jobs, from research and development to complex forming tasks.

Mechanical presses are rigid by design. The stroke length is fixed, and there is no ability to "dwell" under pressure at the bottom of the stroke. Adjustments are far more limited and often require significant mechanical changes.

Noise and Maintenance

As they have fewer moving parts in the core pressing mechanism, hydraulic presses operate much more quietly than mechanical presses. The primary sound comes from the motor and pump, which can be managed.

Mechanical presses, with their flywheel, clutch, brake, and gears, are inherently noisier. They also have more mechanical wear points that require a consistent maintenance schedule.

Understanding the Trade-offs

Neither press type is a perfect solution for every problem. Understanding their limitations is key to avoiding costly mistakes.

The Rigidity of Mechanical Presses

The fixed stroke and speed of a mechanical press make it a highly specialized tool. It is exceptionally efficient for its intended purpose—high-speed, repetitive work—but lacks the flexibility for custom jobs or processes requiring variable force.

The Versatility of Hydraulic Presses

While flexible, hydraulic systems can be more complex. They involve pumps, valves, hoses, and controllers that require specialized knowledge for troubleshooting and maintenance. A leak can be a significant issue, causing downtime and creating safety hazards.

Upfront Cost vs. Lifetime Value

For high-volume manufacturing, a mechanical press often provides a lower cost-per-part due to its high speed, despite potentially higher upfront investment.

A hydraulic press may have a lower initial cost for a given tonnage and is more adaptable to a changing workload, making it a better long-term value for job shops or labs that handle a variety of tasks.

Making the Right Choice for Your Application

Your decision should be driven entirely by the demands of your specific process and business goals.

- If your primary focus is high-volume stamping, blanking, or coining: A mechanical press is the superior choice for its unmatched speed and repeatability.

- If your primary focus is deep drawing, forming, or assembly: A hydraulic press provides the consistent force and control necessary for these processes.

- If your primary focus is maximum force and precision: A hydraulic press is the only option for applications requiring extreme tonnage, pressure holding, or precise control over the entire stroke.

- If your primary focus is versatility for a job shop or R&D: The flexibility of a hydraulic press to handle various jobs with different force and stroke requirements is invaluable.

Choosing the right press begins with understanding whether your process demands speed and repetition or power and control.

Summary Table:

| Feature | Mechanical Press | Hydraulic Press |

|---|---|---|

| Speed | Fast, high-volume production | Slower cycle time |

| Force | Max force at bottom of stroke | Full force throughout the stroke |

| Control | Fixed stroke, limited adjustments | Precise control over speed, stroke, and dwell time |

| Flexibility | Rigid, ideal for repetitive tasks | Highly versatile for various jobs |

| Noise Level | Noisier due to mechanical parts | Quieter operation |

| Maintenance | More mechanical wear points | Complex hydraulic system, potential for leaks |

Still unsure which press is right for your operation? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and reliability. Whether you require the speed of a mechanical press or the control of a hydraulic press, our experts can help you select the ideal solution to enhance your efficiency and productivity. Contact us today to discuss your specific requirements and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy