Cleaning a filter press is a systematic, multi-step process that concludes each filtration cycle. It primarily involves opening the press, manually removing the compacted solid "cake" that has formed between the plates, and inspecting the filter cloths to ensure they are ready for the next run. This is not merely a janitorial task but a critical maintenance procedure that directly impacts the press's efficiency and longevity.

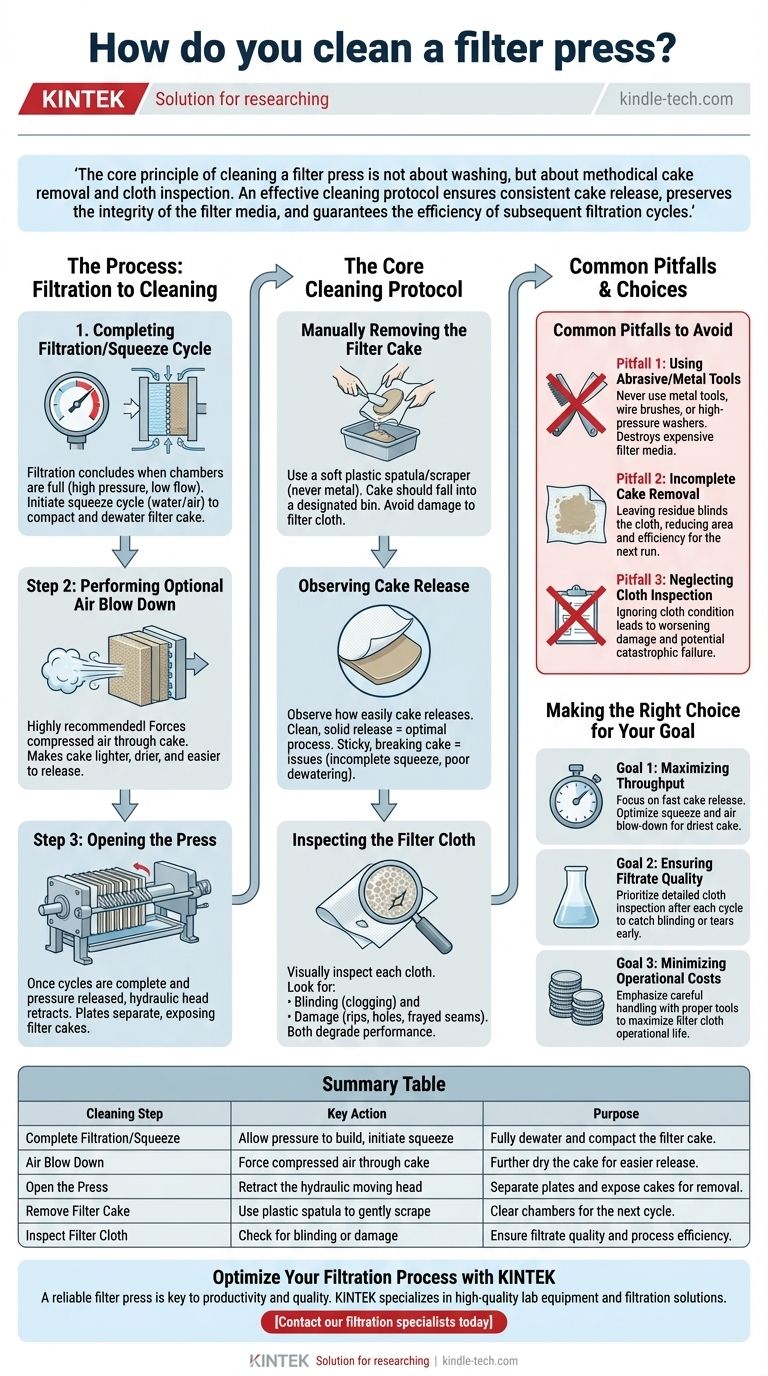

The core principle of cleaning a filter press is not about washing, but about methodical cake removal and cloth inspection. An effective cleaning protocol ensures consistent cake release, preserves the integrity of the filter media, and guarantees the efficiency of subsequent filtration cycles.

The Process: From Filtration to Cleaning

Before you can clean the press, the filtration cycle must be properly completed. The final steps of this cycle are designed to make the cleaning process itself faster and more effective.

Step 1: Completing the Filtration and Squeeze Cycle

The filtration run concludes when the chambers are full of solids, indicated by a sharp rise in feed pressure and a significant drop in the filtrate flow rate.

At this point, for presses equipped with membrane plates, a "squeeze" cycle is initiated. Water or air is pumped behind the flexible membrane on the plates, further compacting and dewatering the filter cake.

Step 2: Performing Optional Air Blow Down

An optional but highly recommended step is the air blow down. Compressed air is forced through the cake, pushing out remaining liquid.

This makes the cake lighter, drier, and more cohesive. A properly dewatered cake is significantly easier to remove and is less likely to stick to the filter cloth.

Step 3: Opening the Press

Once all cycles are complete and the internal pressure is released, the hydraulic system is used to retract the moving head of the press. This separates the filter plates and exposes the filter cakes for removal.

The Core Cleaning Protocol

With the filter press open, the hands-on cleaning work begins. The focus is on two key objectives: removing the cake and verifying the condition of the filter media.

Manually Removing the Filter Cake

The primary task is the physical removal of the filter cake from each chamber. This is typically done with a plastic spatula or scraper.

It is critical to use tools that are softer than the filter cloth material to avoid accidental rips, tears, or abrasion. The cake should fall from the cloths into a designated bin, hopper, or conveyor below the press.

Observing Cake Release

As you remove the cake, pay close attention to how easily it separates from the cloth. This is a key diagnostic observation.

If the cake releases cleanly in a solid sheet, it indicates the process is running optimally. If it is sticky, wet, or breaks apart, it may signal an issue with the preceding steps, such as an incomplete squeeze or insufficient dewatering.

Inspecting the Filter Cloth

After the bulk of the cake is removed, visually inspect the surface of each filter cloth. You are looking for two main issues: blinding and damage.

Blinding occurs when fine particles become lodged in the weave of the cloth, preventing liquid from passing through. Damage includes any rips, holes, or frayed seams. Both conditions will severely degrade the press's performance in the next cycle.

Common Pitfalls to Avoid

An improper cleaning procedure can cause more problems than it solves. Avoiding these common mistakes is essential for maintaining a reliable filtration system.

Using Abrasive or Metal Tools

Never use metal scrapers, wire brushes, or high-pressure power washers directly on the cloths. This is the fastest way to destroy expensive filter media, leading to poor filtrate quality and costly downtime.

Incomplete Cake Removal

Leaving significant amounts of cake residue on the cloths is a common mistake. This residue can blind the cloth, reducing the available filtration area and leading to longer cycle times and wetter cakes in the next run.

Neglecting Cloth Inspection

Simply removing the cake without inspecting the cloth is a missed opportunity. A small tear or a blinded spot that is ignored will only worsen over time, eventually leading to a catastrophic failure that can contaminate a batch of filtrate.

Making the Right Choice for Your Goal

Your cleaning protocol should align with your primary operational objective.

- If your primary focus is maximizing throughput: Your goal is a fast and complete cake release. Ensure the squeeze and air blow-down cycles are optimized to produce the driest possible cake.

- If your primary focus is ensuring filtrate quality: The most critical step for you is the detailed inspection of the filter cloths after each cycle to catch any tears or signs of blinding early.

- If your primary focus is minimizing operational costs: Emphasize careful handling of the filter cloths with appropriate tools to maximize their operational life, as they are a significant recurring expense.

Ultimately, a disciplined and consistent cleaning process is the foundation of reliable and efficient filter press operation.

Summary Table:

| Cleaning Step | Key Action | Purpose |

|---|---|---|

| Complete Filtration/Squeeze | Allow pressure to build, then initiate squeeze cycle. | Fully dewater and compact the filter cake. |

| Air Blow Down | Force compressed air through the cake. | Further dry the cake for easier release. |

| Open the Press | Retract the hydraulic moving head. | Separate plates and expose cakes for removal. |

| Remove Filter Cake | Use a plastic spatula to gently scrape cake from each cloth. | Clear chambers for the next cycle. |

| Inspect Filter Cloth | Check for blinding (clogging) or damage (tears). | Ensure filtrate quality and process efficiency. |

Optimize Your Filtration Process with KINTEK

A reliable filter press is key to your lab's productivity and product quality. Proper cleaning and maintenance are non-negotiable. KINTEK specializes in high-quality lab equipment and consumables, including filtration solutions designed for durability and ease of use.

Let our experts help you select the right filter press and accessories to meet your specific throughput, quality, and cost goals.

Contact our filtration specialists today to discuss your laboratory needs and ensure your processes run smoothly and efficiently.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are some of the problems related to hydraulic power? Manage Leaks, Contamination, and Inefficiency

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid

- What are the most common causes of hydraulic system failure? Prevent Downtime and Costly Repairs

- What are the failures in a hydraulic system? Prevent Costly Downtime with Expert Diagnosis

- What happens if a hydraulic system leaks? Prevent Costly Damage and Safety Hazards