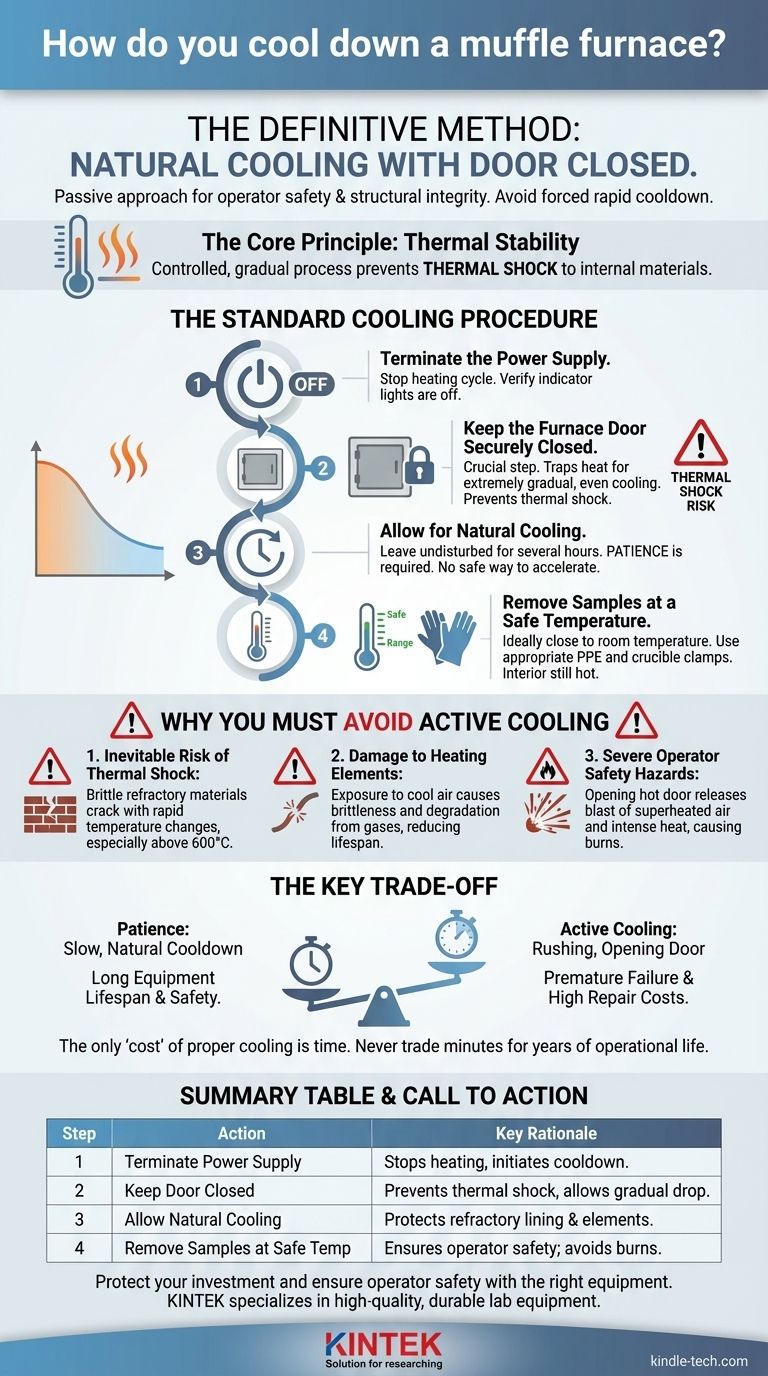

The definitive method for cooling a muffle furnace is to turn off the power supply and allow it to cool down naturally with the door closed. This passive approach is critical for both operator safety and the structural integrity of the furnace. Forcing a rapid cooldown by opening the door at high temperatures can cause irreversible damage.

The core principle of muffle furnace operation is thermal stability. Just as the heating process is controlled and gradual, the cooling process must be as well. A slow, natural cooldown prevents thermal shock to the internal refractory materials and heating elements, ensuring the longevity of the equipment and the safety of the user.

The Standard Cooling Procedure

Properly cooling a muffle furnace is a simple but non-negotiable process. Rushing these steps is the most common cause of premature equipment failure.

Step 1: Terminate the Power Supply

The first action is always to cut power to the furnace. Your controller will indicate that the heating cycle has stopped; for example, a temperature-rise indicator light (often green) will turn off.

Step 2: Keep the Furnace Door Securely Closed

This is the most critical step. Leaving the door closed traps the heated air, allowing for an extremely gradual and even temperature drop.

Opening the door introduces a rush of cool, ambient air, creating a severe temperature gradient. This sudden change is known as thermal shock.

Step 3: Allow for Natural Cooling

The furnace must be left undisturbed to cool on its own. The time required can be significant, often several hours, depending on the furnace's size, insulation, and peak operating temperature.

There is no safe way to accelerate this process. Patience is a required part of the procedure.

Step 4: Remove Samples at a Safe Temperature

Only open the door and remove your samples after the furnace has cooled to a safe temperature, ideally close to room temperature. Even a furnace that appears cool on the outside can hold significant residual heat internally.

Always use appropriate personal protective equipment (PPE) and crucible clamps, as the samples themselves will still be very hot.

Why You Must Avoid Active Cooling

The temptation to speed up the cooling process is a dangerous one. Understanding the risks involved reinforces the importance of the standard procedure.

The Inevitable Risk of Thermal Shock

Muffle furnaces are lined with refractory ceramic materials designed to withstand immense heat. However, these materials are brittle and highly susceptible to cracking if their temperature changes too quickly.

Opening the furnace door above 600°C is especially hazardous, as this rapid change can cause the lining to fracture, leading to costly repairs and compromised performance.

Damage to Heating Elements

The heating elements are also vulnerable. Exposing hot elements to cool air can cause them to become brittle. Furthermore, any volatile or corrosive gases created during the heating process can rapidly degrade the element surface upon exposure to air, drastically reducing their lifespan.

Severe Operator Safety Hazards

Opening the door of a hot furnace will release a blast of superheated air and intense radiant heat. This poses an immediate and severe risk of burns to the operator.

Understanding the Key Trade-off

When operating a muffle furnace, the primary trade-off during shutdown is clear and simple.

Patience vs. Equipment Lifespan

The only "cost" of proper cooling is time. The process is inherently slow.

Attempting to save time by opening the door or using any other method of active cooling directly trades minutes saved for months or years of the furnace's operational life. It is a trade-off that is never worth making.

Pitfall: Introducing Contaminants

Never attempt to cool a furnace with water, compressed air, or any other substance. This will cause catastrophic failure of the refractory lining and likely destroy the heating elements.

This rule extends to your samples and tools—ensure any clamps or crucibles are completely dry before they enter the furnace at any temperature.

Making the Right Choice for Your Goal

Adhering to the correct cooling protocol is essential for any application. Your primary goal will simply reinforce which aspect of the procedure is most critical.

- If your primary focus is equipment longevity: Always prioritize a slow, natural cooldown with the door sealed to prevent thermal shock to the furnace's internal lining.

- If your primary focus is user safety: Never open the furnace door at high temperatures and always wait until it has cooled to a safe level to prevent severe burns.

- If your primary focus is procedural integrity: Ensure the power is fully disconnected and the furnace is secured after use to protect internal components from both damage and ambient moisture.

Properly cooling your muffle furnace is a fundamental part of its safe and effective operation.

Summary Table:

| Step | Action | Key Rationale |

|---|---|---|

| 1 | Terminate Power Supply | Stops the heating cycle and initiates cooldown. |

| 2 | Keep Door Closed | Prevents thermal shock by allowing a gradual, even temperature drop. |

| 3 | Allow Natural Cooling | Protects the refractory lining and heating elements from damage. |

| 4 | Remove Samples at Safe Temp | Ensures operator safety; samples and interior may still be hot. |

Protect your investment and ensure operator safety with the right equipment. Proper furnace operation is fundamental to lab efficiency and success. KINTEK specializes in high-quality, durable lab equipment, including muffle furnaces designed for superior thermal management and long-term reliability. Let our experts help you select the perfect furnace for your application and provide guidance on best practices. Contact KINTEK today to enhance your laboratory's capabilities and safety protocols.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why the melting temperature of ceramic is higher than for most metals? Unpacking Atomic Bond Strength

- At what temperature does ceramic melt? A Guide to Ceramic Heat Resistance

- What is a furnace classified as? Understand the Two Main Types for Your Application

- What is a muffle furnace used in determination of? Precise Ash Content and Material Composition

- What are furnaces usually made of? A Guide to Materials for Extreme Temperatures