Pressing a high-quality KBr pellet is a standard laboratory technique for preparing solid samples for Fourier-Transform Infrared (FTIR) spectroscopy. The process involves thoroughly mixing a small amount of your sample with pure, dry potassium bromide (KBr) powder, loading the mixture into a specialized die, and applying tons of force with a hydraulic press. This high pressure fuses the KBr into a transparent, glass-like disc, trapping the sample within its matrix for analysis.

The ultimate goal is not simply to create a solid disc, but to suspend your sample particles in an infrared-transparent medium. Success depends on three key factors: the purity and dryness of your KBr, the microscopic uniformity of your sample mixture, and the application of sufficient pressure to eliminate light scattering.

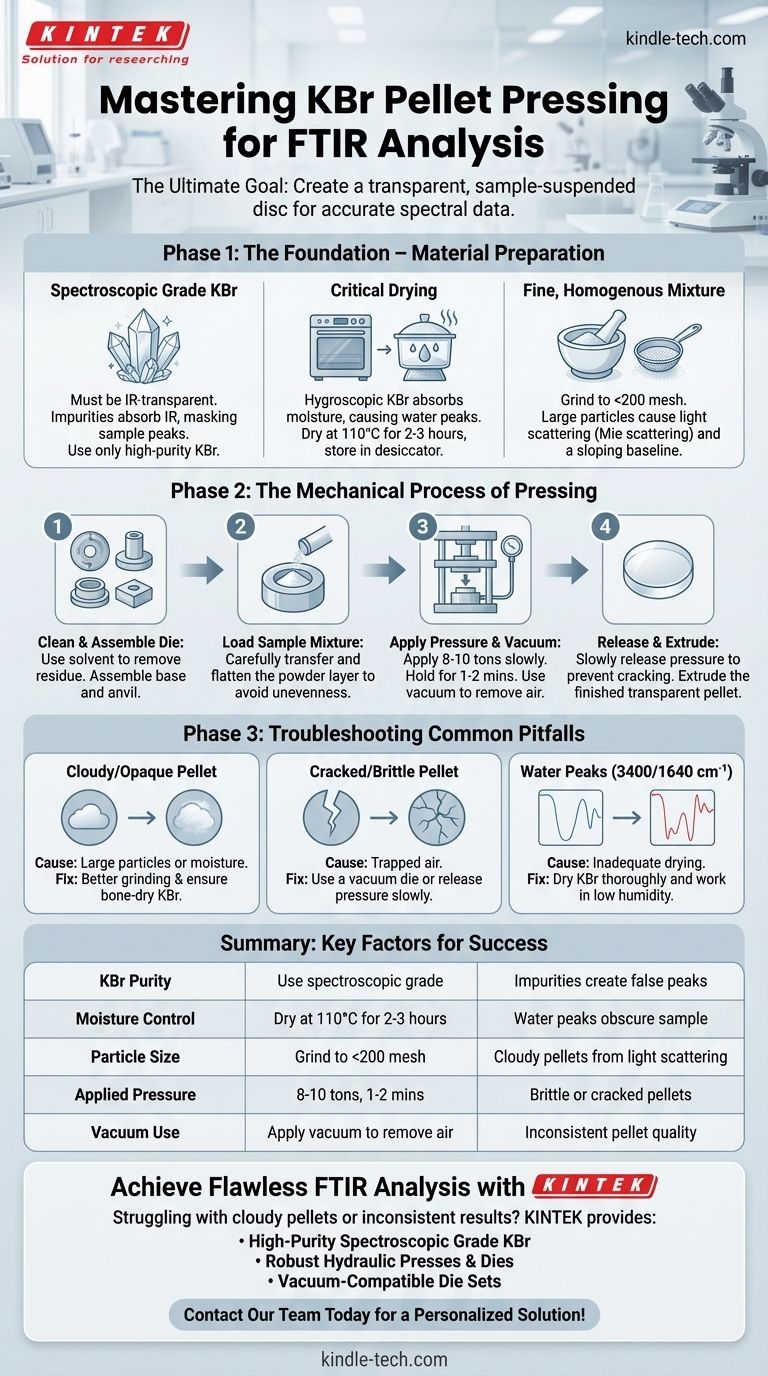

The Foundation: Preparing Your Materials

Before you even touch a press, the quality of your spectrum is determined by the materials you prepare. Rushing these initial steps is the most common source of poor results.

Use Only Spectroscopic Grade KBr

The KBr itself is your analytical window. It must be transparent to infrared light. Any impurities in the salt will absorb IR radiation and appear in your final spectrum, potentially masking the peaks from your actual sample. Always use KBr specifically designated as "spectroscopic grade."

The Critical Step of Drying

Potassium bromide is hygroscopic, meaning it readily absorbs moisture from the air. Since water has very strong and broad absorption bands in the infrared region, even trace amounts will obscure large portions of your spectrum.

To prevent this, KBr powder must be dried in an oven at approximately 110°C for at least two to three hours before use. Store the dried KBr in a desiccator to keep it moisture-free.

Achieve a Fine, Homogenous Mixture

For a clear pellet, the solid particles of your sample must be ground to a size smaller than the wavelength of the infrared light being used. This prevents a phenomenon called Mie scattering, which causes a sloping baseline and reduces spectral quality.

Thoroughly grind your sample (typically ~1 mg) with the dried KBr (typically 200-300 mg) using an agate mortar and pestle until the mixture is a fine, uniform powder. A good rule of thumb is to aim for a particle size of 200 mesh or finer.

The Mechanical Process of Pressing

With your materials properly prepared, you can now move to the die and press. This stage requires cleanliness and methodical application of force.

Step 1: Clean and Assemble the Die

Any oils, dust, or previous sample residue on the die will contaminate your pellet. Thoroughly clean all parts of the die set (the body, base, and anvils/bolts) with a solvent like chloroform or acetone and wipe dry with a clean tissue. Assemble the die by inserting the base and the bottom anvil.

Step 2: Load the Sample Mixture

Carefully transfer your ground KBr/sample mixture into the die cavity. Gently tap the side of the die to ensure the powder forms a flat, even layer. An uneven distribution of powder can lead to a pellet with varying thickness or even a "donut" shape, which compromises analytical accuracy.

Step 3: Apply Pressure

Insert the top anvil or bolt and transfer the entire die assembly to the hydraulic press. Many die sets are designed to be used with a vacuum pump connection; if available, apply a vacuum for several minutes. This removes trapped air and residual moisture, which is the leading cause of cracked or cloudy pellets.

Slowly and steadily apply pressure. A typical load for a standard 13 mm die is 8 to 10 tons. Hold this pressure for one to two minutes. This immense force causes the KBr particles to plastically deform and fuse into a solid, transparent disc.

Step 4: Release and Extrude the Pellet

Gently and slowly release the hydraulic pressure. Releasing the pressure too quickly can cause the pellet to shatter. Carefully disassemble the die and extrude your finished pellet. A high-quality pellet will be transparent or translucent, resembling a small glass window.

Understanding the Common Pitfalls

Troubleshooting is a key part of the KBr technique. Understanding what can go wrong will help you diagnose and fix your process.

Cloudy or Opaque Pellets

This is the most common issue. It is caused by light scattering from particles that are too large or from trapped moisture. The solution is to grind your sample mixture more thoroughly or for a longer time, and to ensure your KBr is bone-dry.

Cracked or Brittle Pellets

Pellets that crack upon extrusion are typically the result of trapped air. Using a vacuum-compatible die is the best way to prevent this. If you don't have one, applying and releasing the pressure more slowly can help.

Interference from Water Peaks

Seeing broad, rolling peaks around 3400 cm⁻¹ and 1640 cm⁻¹ means your pellet is contaminated with water. This points directly to inadequate drying of your KBr or preparing the pellet in a highly humid environment.

Brown Discoloration

If you notice a brown tint in your KBr powder or pellet, you may have overheated the KBr during the drying step. Heating KBr too rapidly or at too high a temperature can cause it to oxidize to potassium bromate (KBrO₃).

Making the Right Choice for Your Goal

Always run a background spectrum using a "blank" pellet made from pure KBr. This helps you identify any contamination from your salt, moisture, or die, distinguishing it from your actual sample.

- If your primary focus is routine qualitative identification: Ensure your pellet is clear enough to minimize light scattering and that your KBr is dry enough that water peaks do not obscure your sample's key functional groups.

- If your primary focus is quantitative analysis: Be meticulous about weighing the sample and KBr to ensure a consistent concentration and pathlength, and always use a vacuum die to create perfectly clear, uniform pellets.

- If you are troubleshooting a noisy or sloping spectrum: Your first suspects should be particle size (inadequate grinding) and moisture content (inadequate drying).

Mastering these fundamentals transforms KBr pellet pressing from a routine chore into a powerful tool for precise and reliable spectroscopic analysis.

Summary Table:

| Key Factor | Best Practice | Common Pitfall |

|---|---|---|

| KBr Purity | Use spectroscopic grade KBr | Impurities create false peaks |

| Moisture Control | Dry at 110°C for 2-3 hours | Water peaks obscure sample data |

| Particle Size | Grind to <200 mesh (finer than IR wavelength) | Cloudy pellets from light scattering |

| Applied Pressure | 8-10 tons for 1-2 minutes (13mm die) | Brittle or cracked pellets |

| Vacuum Use | Apply vacuum to remove trapped air | Inconsistent pellet quality |

Achieve Flawless FTIR Analysis with KINTEK

Struggling with cloudy pellets, water interference, or inconsistent results? The quality of your KBr pellet directly determines the accuracy of your FTIR spectroscopy. At KINTEK, we specialize in the precise lab equipment and consumables you need for reliable sample preparation.

We provide:

- High-Purity Spectroscopic Grade KBr – Ensure a clear analytical window free from impurities.

- Robust Hydraulic Presses and Pellet Dies – Achieve the consistent, high pressure required for transparent pellets.

- Vacuum-Compatible Die Sets – Eliminate trapped air and moisture for perfect results every time.

Let us help you master the technique. Our experts understand the challenges of sample preparation and can recommend the ideal equipment for your specific laboratory needs.

Contact our team today to discuss your FTIR requirements and get a personalized solution!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy